MoP/C composite nanomaterial for alkaline electrocatalytic hydrogen evolution

A nano-material and carbon composite technology, which is applied in the direction of catalyst activation/preparation, chemical/physical process, physical/chemical process catalyst, etc., can solve the problems of poor electrocatalytic hydrogen evolution performance, high cost of raw material preparation, poor product stability, etc., to achieve Good hydrogen evolution performance, good catalytic effect, easy recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

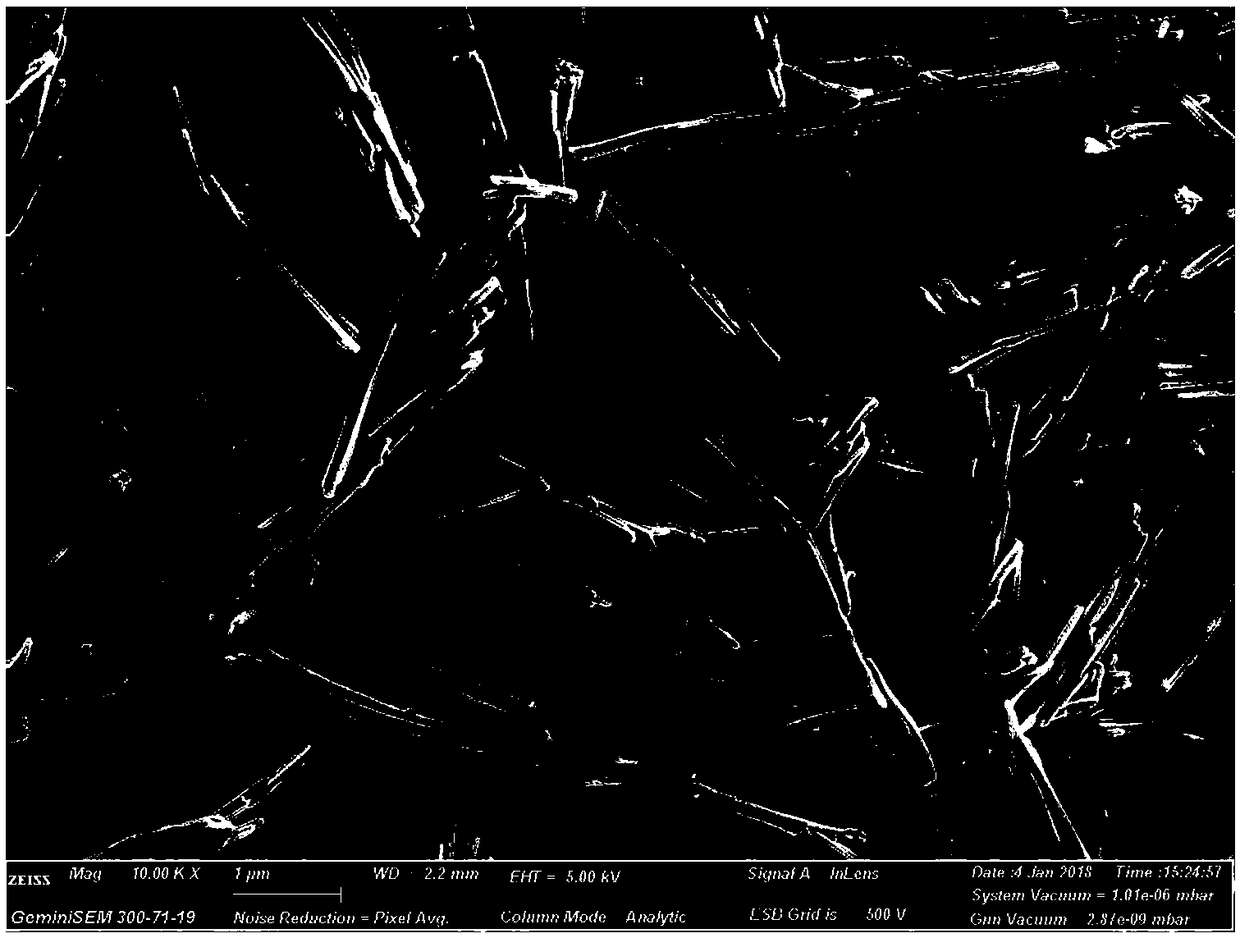

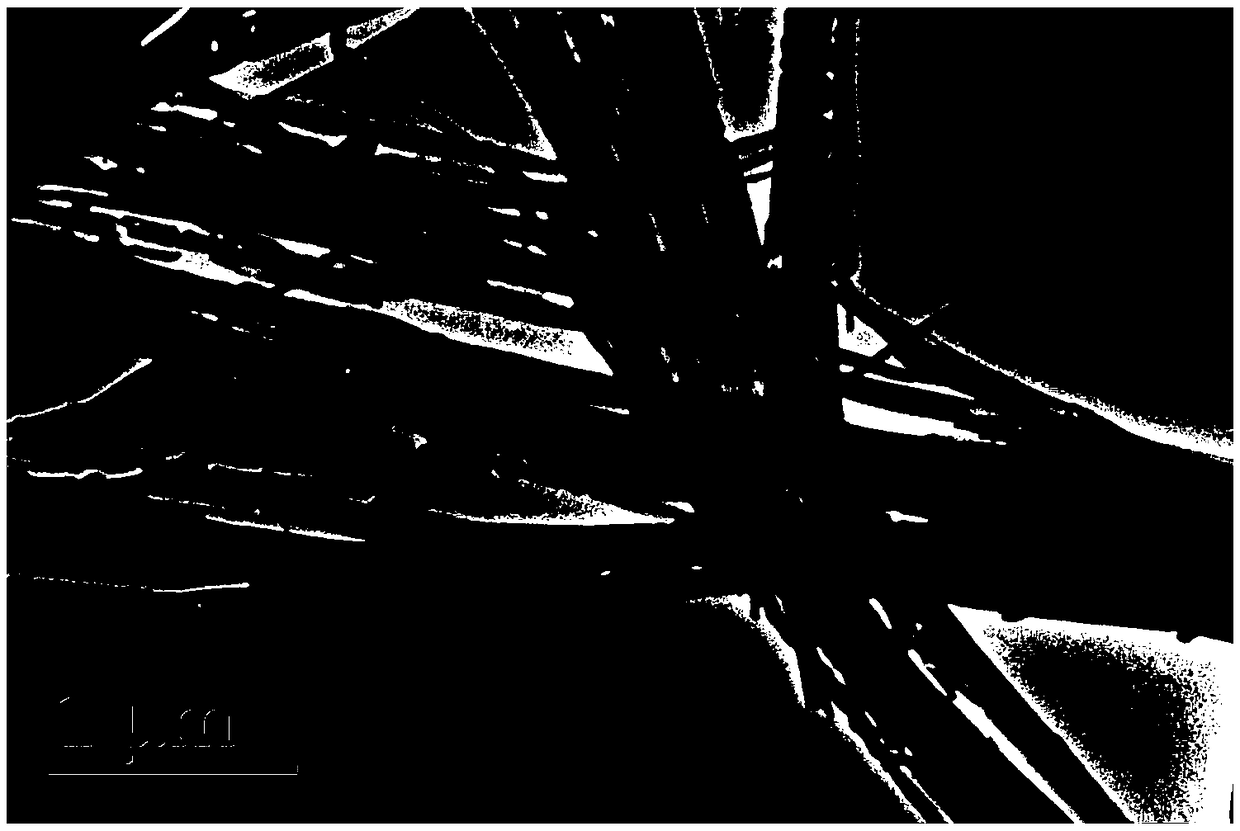

[0030] In the Erlenmeyer flask, weigh 2.48g ammonium molybdate tetrahydrate (NH 4 ) 6 Mo 7 o 24 .4H 2 Add 40ml of uniform deionized water containing 3.28ml of aniline solution to dissolve it, pass through 99.99% nitrogen for protection, the gas flow rate is 25ml / min, at the same time, use microwave to heat to 50 ° C, and then slowly add 1mol / L Adjust the pH value to 4.0 with dilute hydrochloric acid solution, keep at 50 degrees Celsius for 4h to obtain the Mo-MOF precursor intermediate, and then wash with distilled water and ethanol solution respectively for 3 times (the mass of the Mo-MOF precursor intermediate, distilled water and ethanol : volume: volume = 1:45:45), and then centrifuged at 2500 rpm for 15 minutes, and then freeze-dried. Mo-MOF precursors. Transfer the Mo-MOF precursor to the alumina ark, and weigh 2g of sodium hypophosphite in another alumina ark and place it upstream of the tube furnace, 17cm away from the MOF precursor, at 100ml / min with a volume fra...

Embodiment 2

[0036] In the Erlenmeyer flask, weigh 2.48g ammonium molybdate tetrahydrate (NH 4 ) 6 Mo 7 o 24 .4H 2 Add 40ml of uniform deionized water containing 3.28ml of aniline solution to dissolve it, pass through 99.99% nitrogen for protection, the gas flow rate is 20ml / min, at the same time, use microwave to heat to 45°C, and then slowly add 0.8mol / L dilute hydrochloric acid solution to adjust the pH value to 4.5, keep at 45°C for 6h to obtain the Mo-MOF precursor intermediate, and then wash with distilled water and ethanol solution for 3 times respectively (the Mo-MOF precursor intermediate, distilled water and ethanol (mass: volume: volume = 1:40:40), and then centrifuged at 1500 rpm for 15 minutes, and then freeze-dried. The freeze-drying temperature is -45°C, the vacuum is 50Pa, and the drying time is 48h. A precursor containing Mo-MOF is obtained. Transfer the Mo-MOF precursor to the alumina ark, and weigh 2g of sodium hypophosphite in another alumina ark and place it upst...

Embodiment 3

[0039] In the Erlenmeyer flask, weigh 2.48g ammonium molybdate tetrahydrate (NH 4 ) 6 Mo 7 o 24 .4H 2 Add 40ml of uniform deionized water containing 3.28ml of aniline solution to dissolve it, pass through 99.99% nitrogen for protection, the gas flow rate is 30ml / min, at the same time, use microwave to heat to 55 ° C, and then slowly drop 1.2mol / L dilute hydrochloric acid solution to adjust the pH value to 3.5, keep at 55°C for 3h to obtain the Mo-MOF precursor intermediate, and then wash with distilled water and ethanol solution for 3 times respectively (the Mo-MOF precursor intermediate, distilled water and ethanol (mass: volume: volume = 1:40:40), and then centrifuged at 3000 rpm for 10 minutes, and then freeze-dried. The freeze-drying temperature is -55°C, the vacuum is 10Pa, and the drying time is 48h. A precursor containing Mo-MOF is obtained. Transfer the Mo-MOF precursor to the alumina ark, and weigh 2g of sodium hypophosphite in another alumina ark and place it u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com