Triticale bran dietary fiber powder and manufacturing method thereof

A technology of dietary fiber powder and wheat bran, which is applied in the direction of food ingredients as taste improvers, food science, food ingredients, etc., can solve the problems that cannot be widely eaten, waste bran nutrients, and poor taste, etc. Achieve the effect of enriching black wheat nutrients, increasing soluble dietary fiber, and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

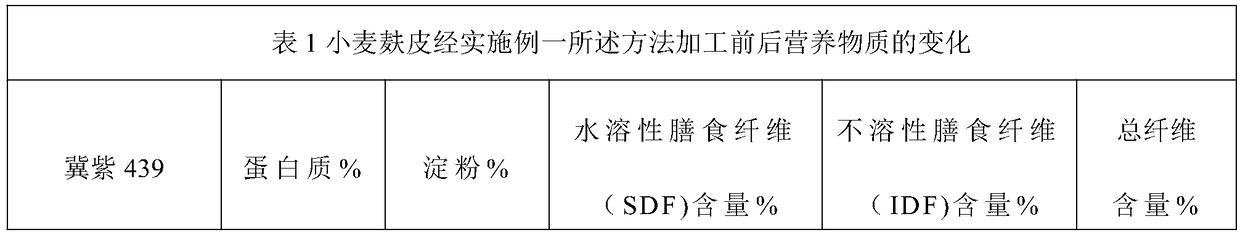

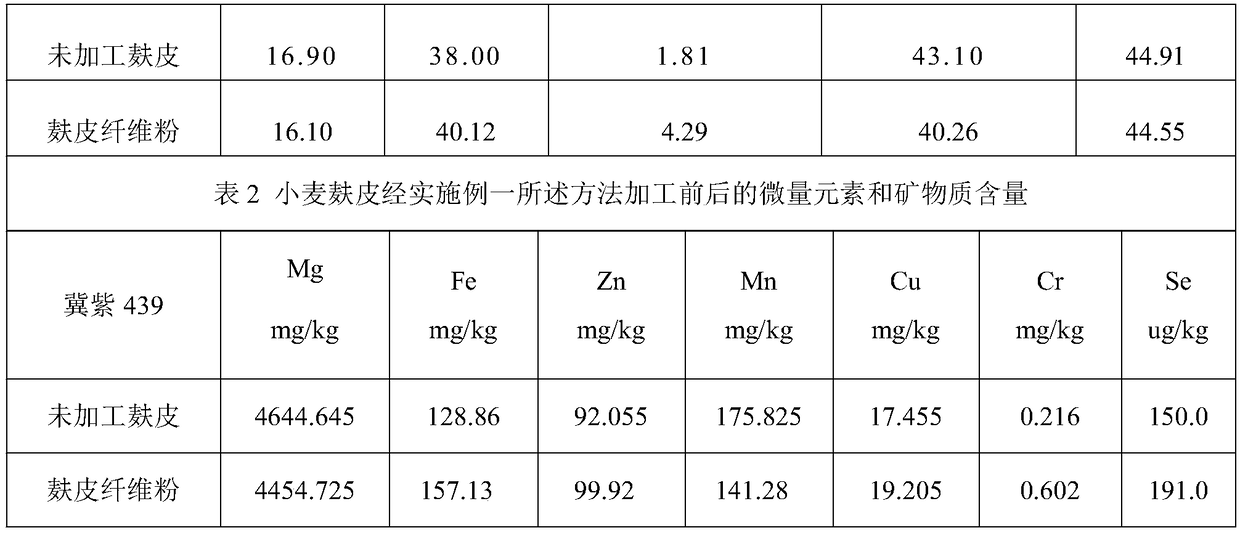

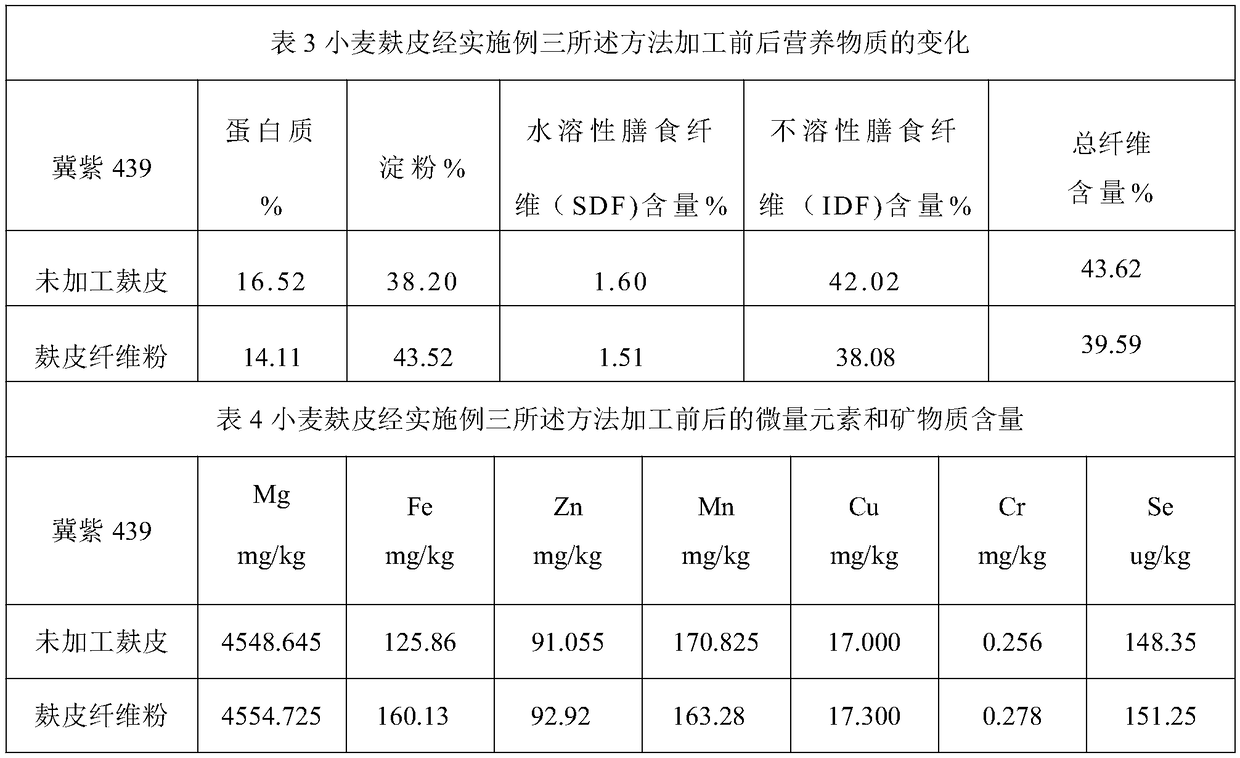

[0024] This embodiment relates to a kind of triticale bran fiber powder and its preparation.

Embodiment 11

[0026] After the black wheat is processed, the bran is collected. Among them, the bran quality of Guantao black wheat "Jizi 439" is the best, and the black wheat bran is processed according to the following methods:

[0027] a, pulverization: the triticale bran is added to the blade pulverizer and pulverized to obtain 60 mesh bran fragments;

[0028] b. Humidification and puffing: Use drinking water to spray wet bran fragments and stir evenly. The mass ratio of the bran fragments to the amount of drinking water sprayed is 100:12, and the humidity of the bran is controlled to reach 22%. , let go and open as the standard; then put it into the twin-screw extruder, and under the conditions of temperature 135 ° C and extruder screw speed 400r / min, the pellets are obtained by twin-screw shaft extrusion and shearing, and the puffing is completed;

[0029] c. Grinding: Add the puffed bran to a broken-wall milling mill for grinding. Under the conditions of grinding rotation speed 350r / ...

Embodiment 12

[0031] After the black wheat is processed, the bran is collected. Among them, the bran quality of Guantao black wheat "Jizi 439" is the best, and the black wheat bran is processed according to the following methods:

[0032] a, pulverization: the triticale bran is added to the blade grinder and pulverized to obtain 55 mesh bran fragments;

[0033] b. Humidification and puffing: Use drinking water to spray wet bran fragments and stir evenly. The mass ratio of the bran fragments to the amount of drinking water sprayed is 100:14, and the humidity of the bran is controlled to reach 24%. , let go and open as the standard; then put it into the twin-screw extruder, and under the conditions of temperature 140°C and extruder screw speed 360r / min, the pellets are obtained by twin-screw shaft extrusion and shearing, and the puffing is completed;

[0034] c. Grinding: Add the puffed bran to a broken-wall milling mill for grinding. Under the conditions of grinding rotation speed 330r / min a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com