Wet preparation method of instant whole-corn nutrition snowflake tablets

A snowflake and corn technology, which is applied in the field of wet preparation of instant whole corn nutritional snowflakes, can solve the problems of reducing the nutritional value of corn flakes, affecting the gelatinization characteristics of starch, affecting the reconstitution of products, etc., and achieving the retention of nutritional components And flavor substances, solve the effect of rough taste, easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the present embodiment, the process steps of preparing instant whole corn nutritional snow flakes are as follows:

[0043] (1) Raw material pretreatment

[0044] Select bad and bad kernels from the prepared dry corn kernels to obtain dry corn kernels with complete shape, yellow color, no mildew, no insects, no peculiar smell, and no peculiar smell;

[0045] (2) Soak

[0046] Measure out 50 kilograms of dry corn kernels for soaking from the dry corn kernels after step (1) pretreatment, add it in the mixing tank and soak with 100 kilograms of lactic acid solution of mass concentration 0.25%, soaking temperature is 38 ℃, Soaking time is 9h;

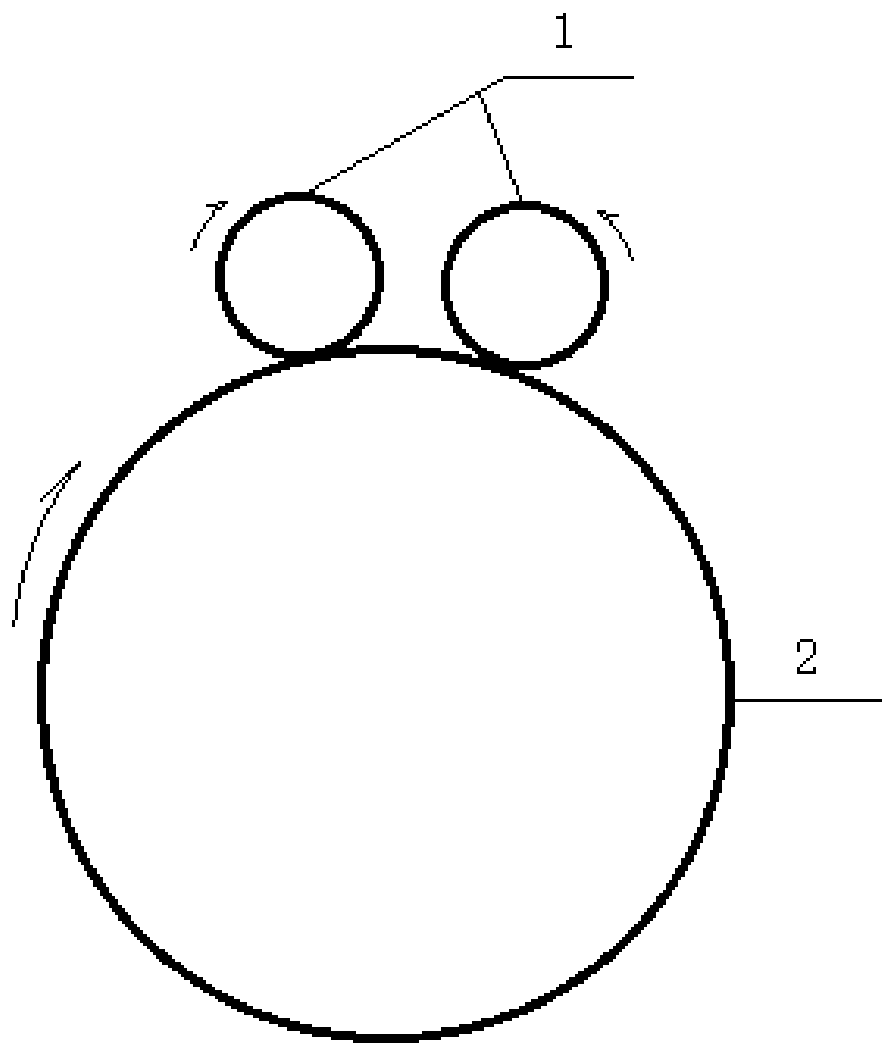

[0047] (3) Refining

[0048] The soaked corn kernels are repeatedly washed with tap water until the pH value of the cleaning solution is neutral, and then the cleaned corn kernels are transported to the colloidal abrasive hopper by a screw conveyor, and tap water is added to pass through the colloid mill for grinding. The addit...

Embodiment 2

[0064] In the present embodiment, the process steps of preparing instant whole corn nutritional snow flakes are as follows:

[0065] (1) Raw material pretreatment

[0066] Select bad and bad kernels from the prepared dry corn kernels to obtain dry corn kernels with complete shape, yellow color, no mildew, no insects, no peculiar smell, and no peculiar smell;

[0067] (2) Soak

[0068] Measure out 50 kilograms of dry corn kernels for soaking from the dry corn kernels after step (1), add it in the soaking vat and soak with 125 kilograms of lactic acid solution of mass concentration 0.10%, soaking temperature is 35 ℃, Soaking time is 10h;

[0069] (3) Refining

[0070] The soaked corn kernels are repeatedly washed with distilled water until the pH value of the cleaning solution is neutral, and then the cleaned corn kernels are transported to the colloidal abrasive hopper by a screw conveyor, and distilled water is added to pass through the colloid mill for grinding. The add-o...

Embodiment 3

[0086] In the present embodiment, the process steps of preparing instant whole corn nutritional snow flakes are as follows:

[0087] (1) Raw material pretreatment

[0088] Select bad and bad kernels from the prepared dry corn kernels to obtain dry corn kernels with complete shape, yellow color, no mildew, no insects, no peculiar smell, and no peculiar smell;

[0089] (2) Soak

[0090] Measure out 50 kilograms of dry corn kernels for soaking from the dry corn kernels after step (1), add it into the soaking tank and soak with 120 kilograms of lactic acid solution of mass concentration 0.70%, soaking temperature is 53 ℃, Soaking time is 6h;

[0091] (3) Refining

[0092] The soaked corn kernels are washed repeatedly with mineral water until the pH value of the cleaning solution is neutral, and then the cleaned corn kernels are transported to the colloidal abrasive hopper by a screw conveyor, and mineral water is added to pass through the colloid mill for refining , the add-on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com