Beef tallow as well as preparation method and application thereof

A kind of technology of butter and oil, applied in the fields of application, edible oil/fat, food science, etc., can solve the problem that the smell of mutton is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

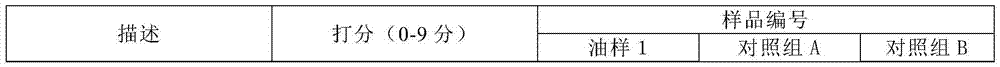

Embodiment 1

[0087] Frying oil 1: containing 1000g butter, 9000g palm oil, 50ppm tertiary butyl hydroquinone

[0088] Wherein the beef tallow raw material is beef waist oil, adds the water of 1% by weight relative to the total weight of beef fat in the cooking pot, and the cooking process is the technology in the present invention, and specific parameters are as follows:

[0089] (1) First, the temperature of the substrate is raised to 110° C. at a rate of 2° C. / min, and the temperature is kept at 110-115° C. until the moisture content of the substrate is 0.1% by weight;

[0090] (2) Then continue to heat up the substrate to 160°C at a rate of 3°C / min, continue heating and keep the temperature at 160-165°C until the moisture content of the substrate is 0.05% by weight, maintain the substrate temperature at 160-165°C, and keep warm After 30 minutes, stop heating and remove the oil residue;

[0091] Control group A: containing 1000g butter, 9000g palm oil, 50ppm tert-butylhydroquinone

[0...

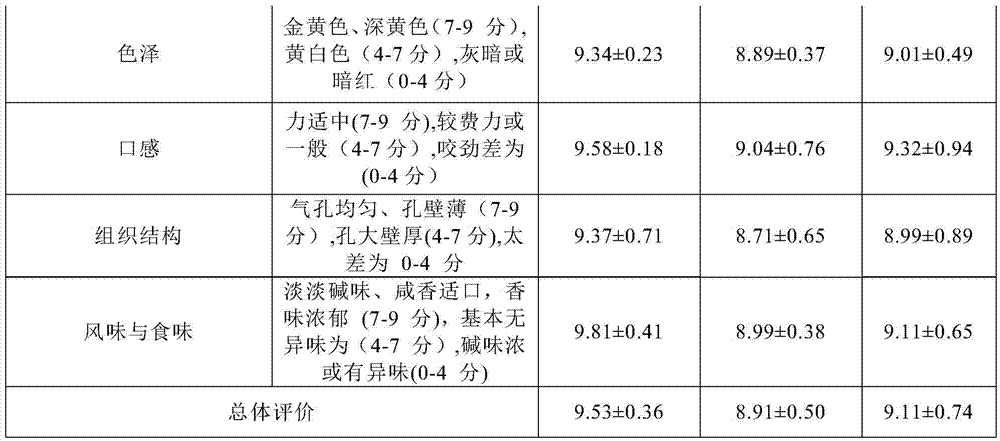

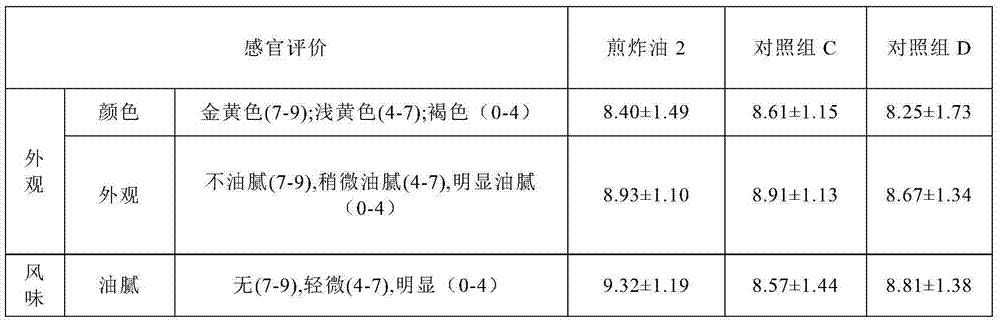

Embodiment 2

[0101] Frying oil 2: Contains 500g butter, 9000g high oleic sunflower oil, 500g rice oil, 800ppm ascorbyl palmitate

[0102] Wherein the beef tallow raw material is beef waist oil, adds the water of 1.5% by weight relative to the total weight of beef fat in the cooking pot, and the cooking process is a technique among the present invention, and specific parameters are as follows:

[0103] (1) First, the temperature is raised to 130° C. at a rate of 1° C. / min, and the temperature is kept at 128-130° C. until the moisture content is 0.05% by weight;

[0104] (2) Then continue to heat up to 180°C at a rate of 2°C / min, continue heating and keep the temperature at 175-180°C until the moisture content of the substrate is 0.01% by weight, continue to keep warm for 10min, stop heating, and remove the oil residue;

[0105] Control group C: containing 500g butter, 9000g high oleic sunflower oil, 500g rice oil, 800ppm ascorbyl palmitate

[0106] Wherein the tallow raw material is tripe ...

Embodiment 3

[0119] Frying oil 3: Contains 9500g butter, 200g corn oil, 300g tea seed oil, 1000ppm vitamin E

[0120] Wherein the beef tallow raw material is beef waist oil, adds the water of 0.5% by weight relative to the total weight of beef fat in the cooking pot, and the cooking process is a technique among the present invention, and specific parameters are as follows:

[0121] (1) First, the temperature is raised to 120° C. at a rate of 3° C. / min, and the temperature is kept at 120-125° C. until the moisture content is 0.1% by weight;

[0122] (2) Then continue to heat up to 170°C at a rate of 5°C / min, continue heating and keep the temperature at 170-173°C until the moisture content of the substrate is 0.01% by weight, continue to keep warm for 10min, stop heating, and remove the oil residue;

[0123] Control group E: 9700g butter, 200g corn oil, 100g tea seed oil, 1000ppm vitamin E

[0124] Wherein the beef tallow raw material is beef waist oil, adds the water of 0.5% by weight rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com