Extraction method and application of okra dietary fiber

A technology of dietary fiber and extraction method, which is applied in the field of extraction of okra dietary fiber, can solve the problems of high dietary fiber yield, unsuitability for large-scale production, poor taste, etc., to reduce extraction cost, improve rough taste, water absorption and The effect of water solubility enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

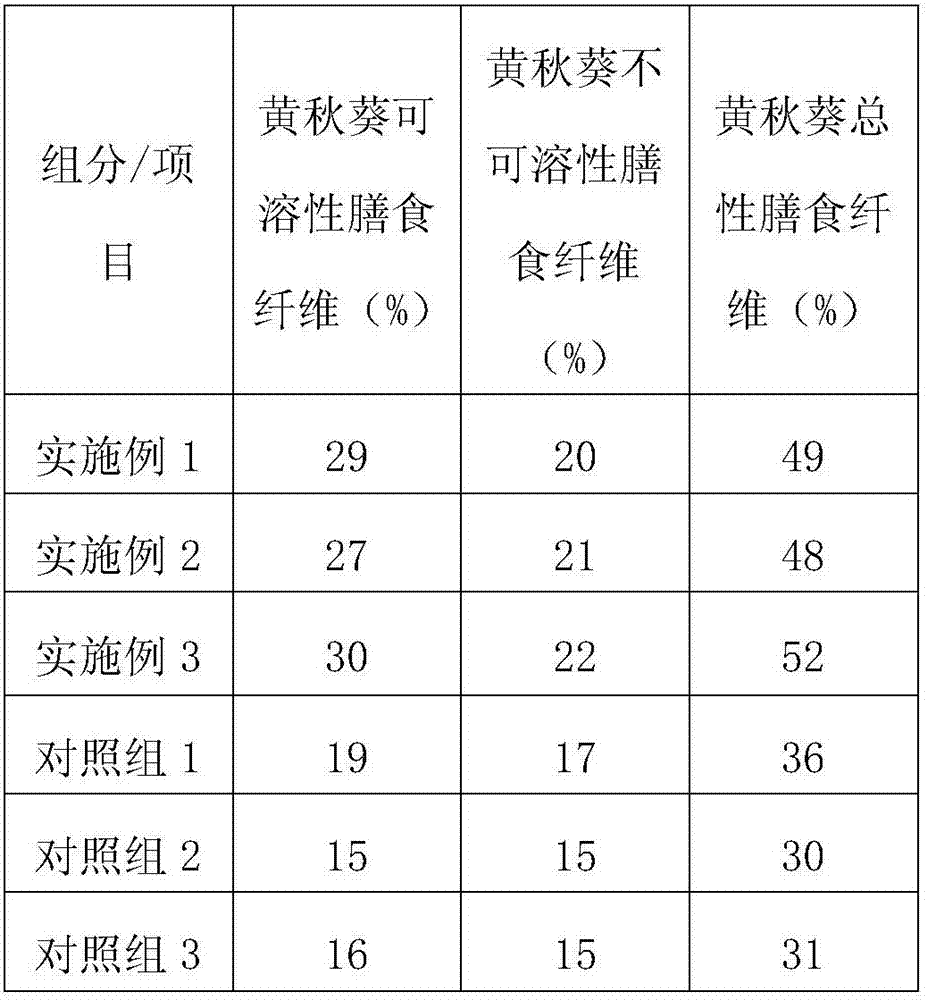

Examples

Embodiment 1

[0024] A kind of extraction method of okra dietary fiber of the present embodiment comprises the following steps:

[0025] (1) Pretreatment: Wash the fresh okra, put it in a drying oven and dry it to constant weight at 55° C., grind the dried okra into powder, pack it into a bag and seal it for later use;

[0026] (2) Ultrasonic treatment: Mix and stir the above powder and distilled water evenly at a weight ratio of 1:25, and treat with ultrasonic wave for 8 minutes, the power of ultrasonic wave is 150W, and the frequency is 250KHz;

[0027] (3) Enzymolysis: mix and stir the mixture after the above-mentioned ultrasound with 0.2% cellulase, 1% magnesium chloride and 3% calcium dihydrogen phosphate by weight of the mixture after the ultrasound, and put it into a shaker Shake the enzymolysis in a water bath at 45°C for 1 hour, after the end of the enzymolysis, transfer to a water bath to inactivate the enzyme at 80°C for 8 minutes, cool to obtain the enzymolysis solution;

[002...

Embodiment 2

[0034] A kind of extraction method of okra dietary fiber of the present embodiment comprises the following steps:

[0035] (1) Pretreatment: Wash the fresh okra, put it in a drying oven and dry it to constant weight at 65° C., grind the dried okra into powder, pack it into a bag and seal it for later use;

[0036] (2) Ultrasonic treatment: Mix the above powder and distilled water with a weight ratio of 1:35 and stir evenly, and treat with ultrasonic wave for 12 minutes, the power of ultrasonic wave is 200W, and the frequency is 350KHz;

[0037] (3) Enzymolysis: mix and stir the mixture after the above-mentioned ultrasound with 0.4% cellulase, 3% magnesium chloride and 5% calcium dihydrogen phosphate by weight of the mixture after the ultrasound, and put it into a shaker Shake the enzymolysis in a water bath at 55°C for 2 hours, after the end of the enzymolysis, transfer to a water bath to inactivate the enzyme at 90°C for 12 minutes, cool to obtain the enzymolysis solution;

...

Embodiment 3

[0044] A kind of extraction method of okra dietary fiber of the present embodiment comprises the following steps:

[0045] (1) Pretreatment: Wash the fresh okra, put it in a drying oven and dry it at 60°C until it reaches a constant weight, and grind the dried okra into powder, pack it into a bag and seal it for later use;

[0046] (2) Ultrasonic treatment: Mix and stir the above powder and distilled water at a weight ratio of 1:30, and treat with ultrasonic wave for 10 minutes, the power of ultrasonic wave is 180W, and the frequency is 300KHz;

[0047] (3) Enzymolysis: mix and stir the mixture after the above-mentioned ultrasound with 0.3% cellulase, 2% magnesium chloride and 4% calcium dihydrogen phosphate by weight of the mixture after the ultrasound, and put it into a shaker Enzymolysis was carried out in a water bath at 50°C for 1.5 hours, and after the end of the enzymolysis, it was transferred to a water bath to inactivate the enzyme at 85°C for 10 minutes, cooled to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com