Preparation method of fermented capsicum sections in bag

A technology for fermenting peppers and peppers, which is applied in the fields of biotechnology and food, can solve the problems of uncontrollable fermentation, high cost of pepper segments, large discharge of high-salt and high-acid wastewater, and achieve the effect of inhibiting infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

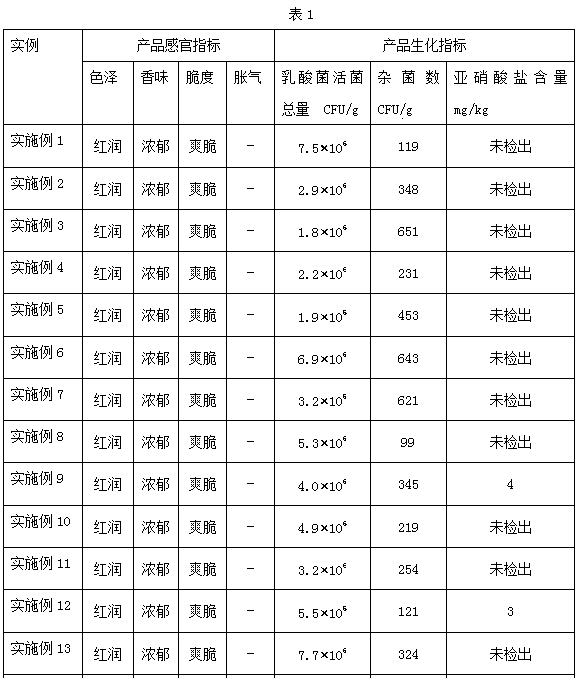

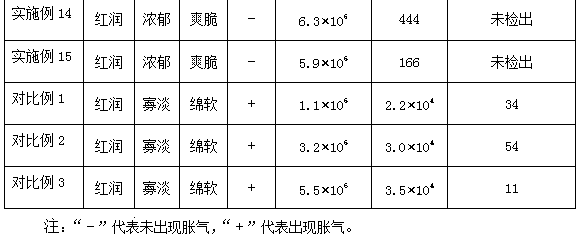

Examples

Embodiment 1

[0083] A method for preparing fermented pepper segments in a bag includes the following steps:

[0084] 1) Pretreatment

[0085] Remove impurities and inedible parts of fresh peppers, clean them, and set aside;

[0086] 2) Disinfection and cleaning

[0087] Disinfect the peppers treated in step 1) with a disinfectant solution for 3 minutes to control the total number of microorganisms below 300 CFU / g; rinse with clean water for 3 minutes and drain;

[0088] 3) Slitting

[0089] Cut the peppers processed in step 2) to obtain pepper segments with a length of 1.5 cm for use;

[0090] 4) Preparation of fermentation solution

[0091] A. Weigh, based on the total weight of each kilogram of pepper segment and fermentation solution, weigh the following components:

[0092] Sodium ethylenediaminetetraacetate 0.10g / kg, potassium sorbate 0.30g / kg, sodium metabisulfite 0.05g / kg, sodium dehydroacetate 0.30g / kg, iodized salt 80.00g / kg, citric acid 5.00g / kg, Lactic acid bacteria powder 0.10g / kg and Lact...

Embodiment 2

[0100] A method for preparing fermented pepper segments in a bag includes the following steps:

[0101] 1) Pretreatment

[0102] Remove impurities and inedible parts of fresh peppers, clean them, and set aside;

[0103] 2) Disinfection and cleaning

[0104] Disinfect the peppers treated in step 1) with a disinfectant for 5 minutes to control the total number of microorganisms below 300 CFU / g; rinse with water for 5 minutes and drain;

[0105] 3) Slitting

[0106] Cut the chili peppers processed in step 2) to obtain chili sections with a length of 2.0 cm for use;

[0107] 4) Preparation of fermentation solution

[0108] A. Weigh, based on the total weight of each kilogram of pepper segment and fermentation solution, weigh the following components:

[0109] Sodium ethylenediaminetetraacetate 0.25g / kg, potassium sorbate 0.50g / kg, sodium metabisulfite 0.10g / kg, sodium dehydroacetate 0.50g / kg, iodized salt 150.00g / kg, citric acid 10.00g / kg, Lactic acid bacteria powder 0.50g / kg and Lactobacillu...

Embodiment 3

[0117] A method for preparing fermented pepper segments in a bag includes the following steps:

[0118] 1) Pretreatment

[0119] Remove impurities and inedible parts of fresh peppers, clean them, and set aside;

[0120] 2) Disinfection and cleaning

[0121] Disinfect the peppers treated in step 1) with a disinfectant for 4 minutes, and control the total number of microorganisms below 300 CFU / g; rinse with clean water for 4 minutes and drain;

[0122] 3) Slitting

[0123] Cut the peppers processed in step 2) to obtain pepper segments with a length of 1.8 cm for use;

[0124] 4) Preparation of fermentation solution

[0125] A. Weigh, based on the total weight of each kilogram of pepper segment and fermentation solution, weigh the following components:

[0126] Sodium ethylenediaminetetraacetate 0.15g / kg, potassium sorbate 0.40g / kg, sodium metabisulfite 0.08g / kg, sodium dehydroacetate 0.40g / kg, iodized salt 110.00g / kg, citric acid 8.00g / kg, Lactic acid bacteria powder 0.30g / kg and Lactobacil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com