A method for preparing silica sol by slurrying electrolysis of silicon micropowder

A technology of silica sol and silicon micropowder, which is applied to electrolysis components, electrolysis processes, cells, etc., can solve the problems of high environmental damage and high preparation cost, and achieve the effects of high utilization rate of raw materials, improved yield, and easy and controllable process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

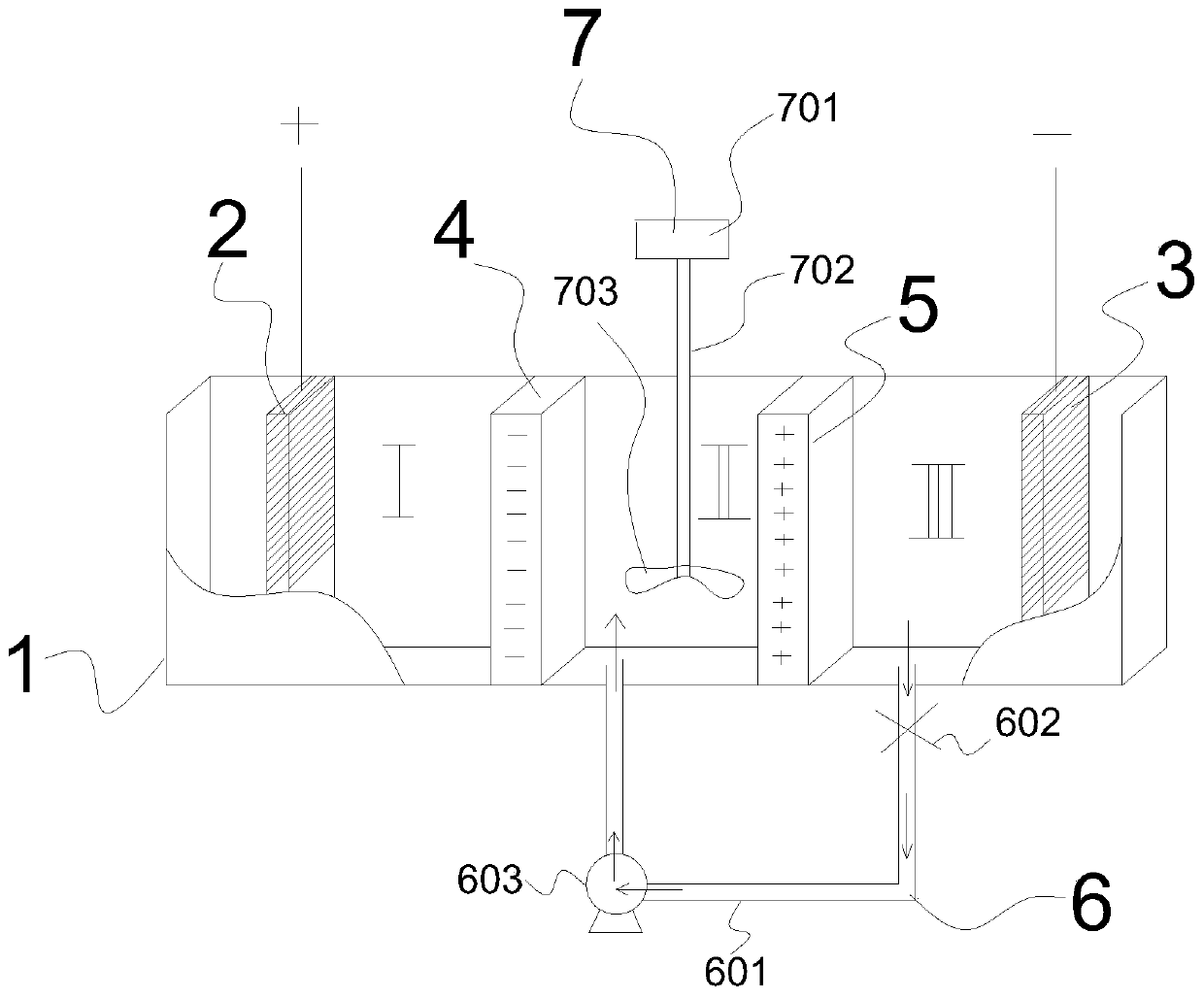

[0047] combine as figure 1 In the shown bipolar membrane electrolyzer device, this embodiment provides a method for preparing silica sol by slurrying and electrolyzing silicon micropowder, including:

[0048] 1000kg of silicon micropowder recovered in a silicon smelter (the test result of the main component of the silicon micropowder is: SiO 2 92%, C6%, Fe 2 o 3 1.1%, MgO0.1%, CaO 0.1%), with a mass fraction of 30% sodium hydroxide solution, according to the solid-liquid ratio between silicon micropowder and sodium hydroxide solution: 3-6:1 mixed slurry, and Pump the mixed slurry to figure 1 In the intermediate reaction chamber II in the electrolysis reaction device shown, adjust the initial pH of the mixed slurry to 12-14, and continue to stir and mix under stirring conditions. At the same time, turn on the external electrolysis power supply, control the electrolysis voltage to 2.5-5V, and the current density to 350-800A / m 2 , The mixing temperature of the reaction slur...

Embodiment 2

[0051] combine as figure 1 In the shown bipolar membrane electrolyzer device, this embodiment provides a method for preparing silica sol by slurrying and electrolyzing silicon micropowder, including:

[0052] Take 500kg of silicon micropowder recovered in a silicon smelter (the test result of the main component of the silicon micropowder is: SiO 2 90%, C8%, Fe 2 o 3 1.1%, MgO0.1%, CaO 0.1%), with a mass fraction of 30% sodium hydroxide solution, according to the solid-liquid ratio between silicon micropowder and potassium hydroxide: 1-5:1 mixed slurry, and After mixing, the slurry is pumped to figure 1 In the intermediate reaction chamber II of the electrolytic reaction device shown, adjust the initial pH of the mixed slurry to 10-12, and continue stirring and mixing under stirring conditions. At the same time, turn on the external electrolysis power supply, control the electrolysis voltage to 3.5-4.5V, and the current density to 450-600A / m 2 , The mixing temperature of ...

Embodiment 3

[0055] combine as figure 1 In the shown bipolar membrane electrolyzer device, this embodiment provides a method for preparing silica sol by slurrying and electrolyzing silicon micropowder, including:

[0056] 600kg of silicon micropowder recovered in a certain chemical smelting plant (the detection result of the main components of the silicon micropowder is the same as that in Example 3), with a mass fraction of 30% sodium hydroxide solution, according to the solid-liquid ratio between the silicon micropowder and the sodium hydroxide solution Ratio: 10:1 mixing slurry, and pump the mixed slurry to such as figure 1 In the intermediate reaction chamber II of the electrolytic reaction device shown, adjust the initial pH of the mixed slurry to 12-15, and continue stirring and mixing under stirring conditions. At the same time, turn on the external electrolysis power supply, control the electrolysis voltage to 2.5-4.5V, and the current density to 350-650A / m 2 , The mixing tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com