High-acid and high-peptide fermented soybean meal and preparation method thereof

A technology for fermenting soybean meal and high-peptide, which is applied in applications, animal feed, animal feed, etc. It can solve the problems of low content of small peptides and organic acids, incomplete antigen degradation, etc., and achieve improved digestion utilization and total acid content of soybean meal and small peptide content are high, and the effect of increasing lactic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

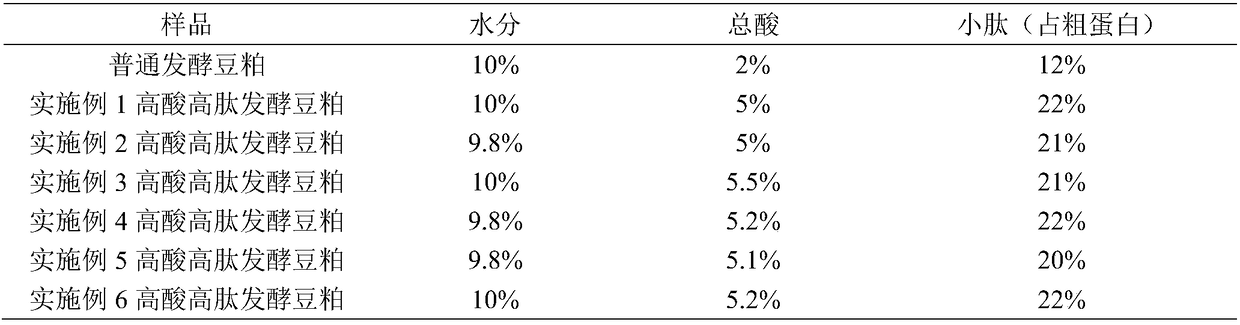

Examples

Embodiment 1

[0026] The cultivation of primary strains of lactic acid bacteria:

[0027] Get 2% glucose by weight, 1% peptone, 1% yeast extract, 1% beef extract, 0.5% sodium acetate, 0.05% magnesium sulfate, 0.025% manganese sulfate, 0.1% dihydrogen phosphate Potassium, 0.1% Tween 80, and water as the balance, sterilized at 121°C for 20 minutes, inoculated with glycerin-preserved lactic acid bacteria strains, and cultured at 37°C for 48 hours to obtain lactic acid bacteria seed liquid for future use.

[0028] Cultivation of primary strains of Aspergillus oryzae:

[0029] Take 1 part of bran, 6 parts of corn flour, and 1 part of water in parts by weight, mix well, sterilize at 121°C for 20 minutes, add mold powder, and culture at 35°C for 48 hours to obtain Aspergillus oryzae seed liquid, which is set aside.

[0030] Cultivation of primary strains of Bacillus coagulans:

[0031] Take 1% peptone, 0.5% yeast extract, 2% glucose, and 1% sodium chloride by weight percentage, mix well, sterili...

Embodiment 2

[0038] The cultivation of primary strains of lactic acid bacteria:

[0039] Get 2% glucose by weight, 1% peptone, 1% yeast extract, 1% beef extract, 0.5% sodium acetate, 0.05% magnesium sulfate, 0.025% manganese sulfate, 0.1% dihydrogen phosphate Potassium, 0.1% Tween 80, and water as the balance, sterilized at 121°C for 20 minutes, inoculated with glycerin-preserved lactic acid bacteria strains, and cultured at 37°C for 48 hours to obtain lactic acid bacteria seed liquid for future use.

[0040] Cultivation of primary strains of Rhizopus oryzae: Take 3 parts of bran, 3 parts of corn flour, and 3 parts of water in parts by weight, mix well, sterilize at 121°C for 20min, insert mold powder, and cultivate at 35°C for 48h to obtain Aspergillus oryzae Seed liquid, spare.

[0041] Cultivation of primary strains of Bacillus coagulans:

[0042] Take 1% peptone, 0.5% yeast extract, 2% glucose, and 1% sodium chloride by weight percentage, mix well, sterilize at 121°C for 20 minutes, ...

Embodiment 3

[0049] The cultivation of primary strains of lactic acid bacteria:

[0050] Get 2% glucose by weight, 1% peptone, 1% yeast extract, 1% beef extract, 0.5% sodium acetate, 0.05% magnesium sulfate, 0.025% manganese sulfate, 0.1% dihydrogen phosphate Potassium, 0.1% Tween 80, and water as the balance, sterilized at 121°C for 20 minutes, inoculated with glycerin-preserved lactic acid bacteria strains, and cultured at 37°C for 48 hours to obtain lactic acid bacteria seed liquid for future use.

[0051] Cultivation of primary strains of Aspergillus oryzae:

[0052] Take 2 parts of bran, 4 parts of corn flour, and 3 parts of water in parts by weight, mix them evenly, sterilize at 121°C for 20 minutes, add mold powder, and cultivate at 35°C for 48 hours to obtain Aspergillus oryzae seed liquid, which is set aside.

[0053] Cultivation of primary strains of Bacillus coagulans:

[0054] Take 1% peptone, 0.5% yeast extract, 2% glucose, and 1% sodium chloride by weight percentage, mix we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com