Movable type complete equipment for thermal desorption of polluted waste and method

A complete set of equipment, thermal desorption technology, applied in lighting and heating equipment, removal of solid waste, restoration of polluted soil, etc., can solve the problems of low thermal desorption temperature, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

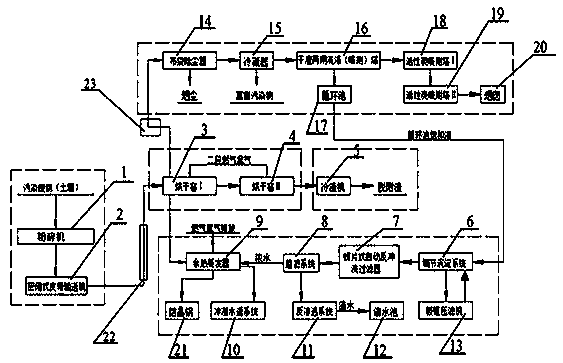

[0032] Example 1: Such as figure 1 As shown, the mobile pollutant waste thermal desorption complete set of equipment includes a feed module, a thermal phase separation module, a discharge module, a water treatment module, and an exhaust gas treatment module; the feed module is connected to the thermal phase separation module, and The thermal phase separation module is respectively connected with the discharge module, the water treatment module, and the exhaust gas treatment module, and the exhaust gas treatment module is connected with the water treatment module.

[0033] The feed module includes a pulverizer 1, a closed belt conveyor 2 and a screw feeder 22; the discharge port of the pulverizer 1 is in communication with the input end of the closed belt conveyor 2, and the closed belt conveyor 2 The output end of the screw feeder 22 is connected to the feed port;

[0034] The thermal phase separation module includes a drying kiln I3, a drying kiln II4, and a mixed gas warehouse 2...

Embodiment 2

[0044] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1. The difference is that the bag filter 14 is a pulse-type bag filter, and the bag filter 14 can also introduce compressed air through the air duct. The bag filter 14 The bottom of the ash hopper is provided with a manual flap valve and a heavy hammer type ash unloading valve. The side wall of the ash hopper is provided with an inspection hole and an ash stabbing port; the condenser 15 is a glass tube condenser. The tube group is installed vertically, the steam travels through the tube pass, and the condensate travels through the shell pass to form a reverse convection heat exchange form. The maximum temperature difference: ≤120°; the feed module, thermal phase separation module, discharge module, and water treatment The equipment of the module and the exhaust gas treatment module are all installed on a base, and the base is movable; a mist removal tower is added between the scrubbing tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com