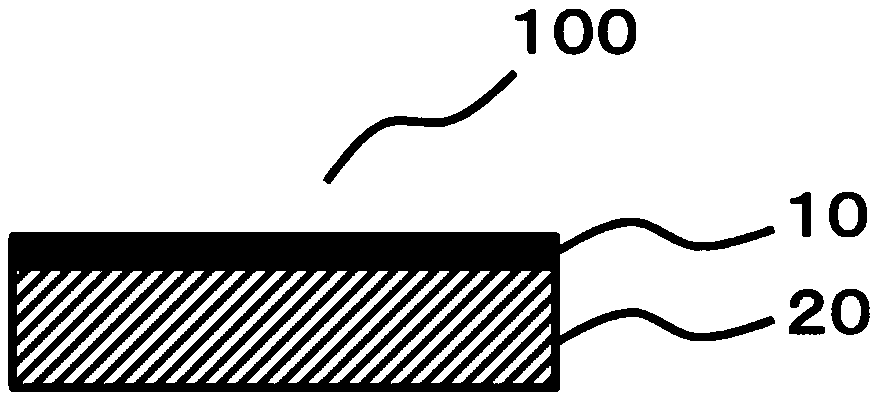

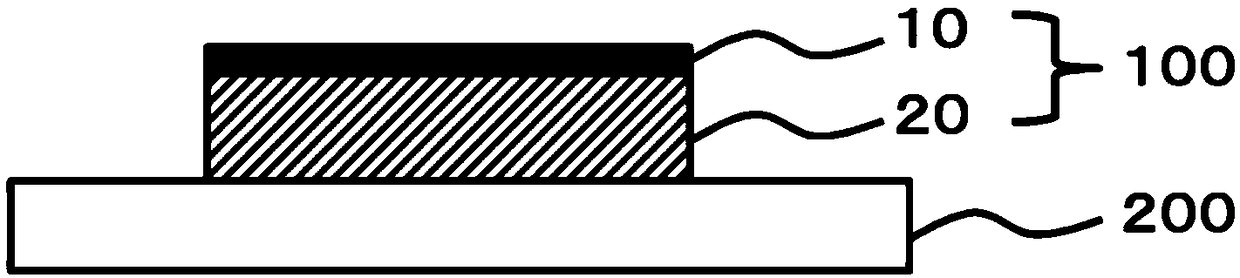

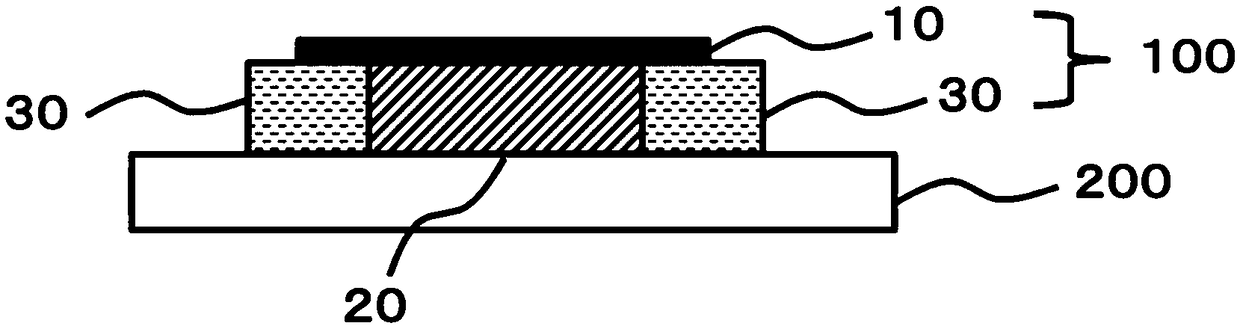

Polysulfide adhesive tape

A sulfide-based, polysulfide technology, applied in the direction of non-polymer organic compound adhesives, graft polymer adhesives, adhesive types, etc., can solve the problem of pre-standing adherends, long-term, time-consuming issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146]100 parts by weight of polysulfide oligomer (manufactured by Toray Fine Chemical, product name "THIOKOL LP-55"), 1 part by weight each of UV initiator (manufactured by BASF Corporation, product name "Irgacure 819" and "Irgacure 651"), Tertiary amine catalyst (manufactured by Tokyo Chemical Industry Co., Ltd., product name "2,4,6-tris(dimethylaminomethyl)phenol") 0.1 parts by weight, butyl acrylate 10 parts by weight, N-vinylpyrrolidone 7 parts by weight, A polysulfide polymer was prepared by mixing 3 parts by weight of acrylic acid, 3 parts by weight of 1,6-hexanediol diacrylate, and 1.5 parts by weight of a bifunctional isocyanate crosslinking agent (manufactured by Asahi Kasei Chemicals, product name "Duranate 50M-HDI") . The above-mentioned polysulfide polymer was coated on the treated surface of a release liner (manufactured by Mitsubishi Polyester Film Co., Ltd., trade name "MRE", thickness 38 μm) to obtain a coating layer. A second release liner (manufactured by M...

Embodiment 2

[0151] An adhesive tape (2) was produced in the same manner as in Example 1 except that butyl acrylate, N-vinylpyrrolidone, and acrylic acid were not added when preparing the polysulfide polymer.

[0152] The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com