Lithium ion battery composite positive pole material and preparation method thereof

A composite positive electrode material and lithium-ion battery technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that the increase in capacity is not very effective, and achieve improved charge and discharge capacity, improved conductivity, and high battery capacity. The effect of chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

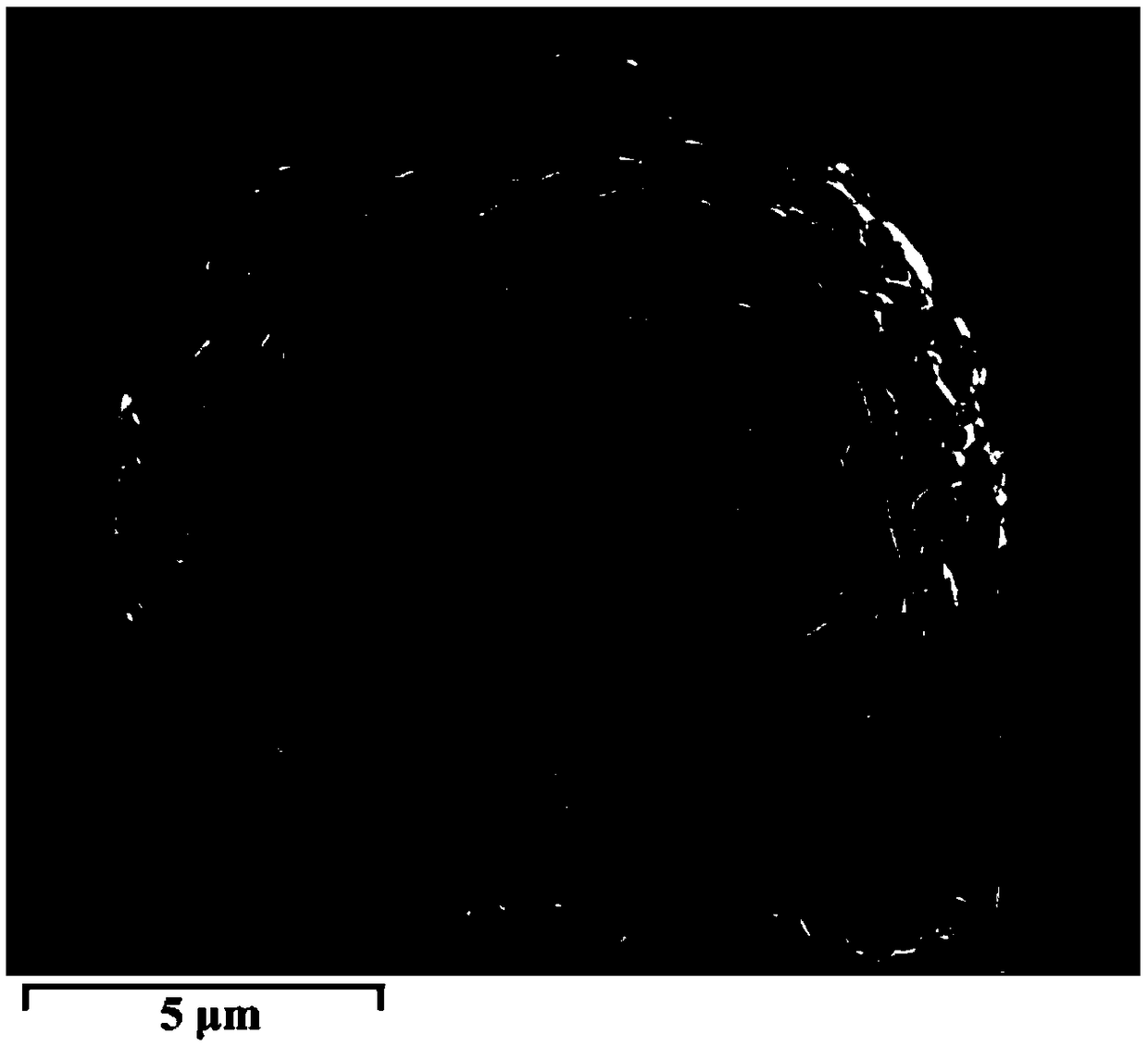

[0035] The bulk cathode material is LiNi with a median particle size of about 10 μm 0.6 co 0.2 mn 0.2 o 2 , which is the sample before improvement, such as figure 1 shown.

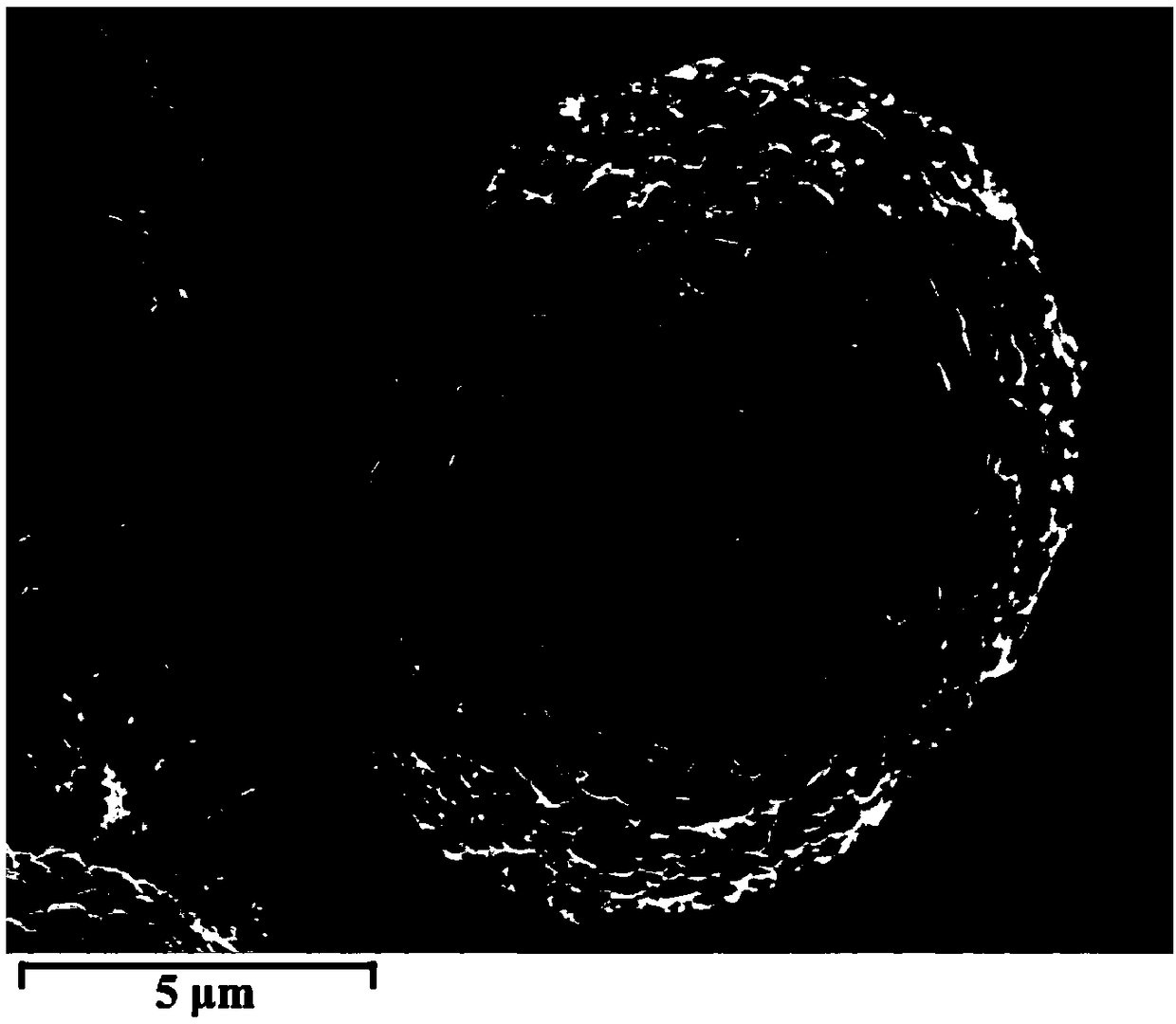

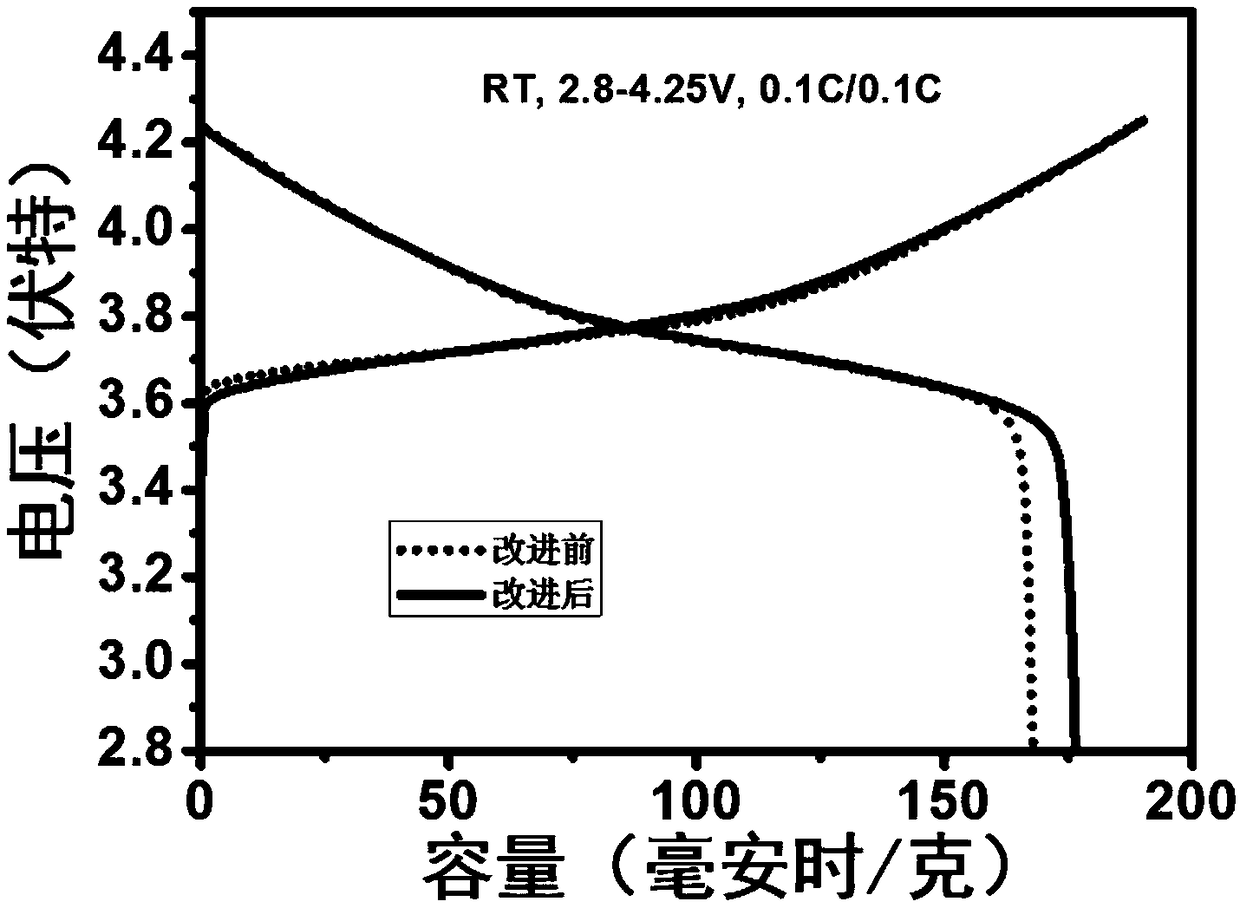

[0036] 1mol of LiNi 0.6 co 0.2 mn 0.2 o 2 After preliminary grinding with 0.08mol lithium hydroxide, 0.085mol nickel acetate, 0.015mol cobalt acetate and 0.002mol lithium fluoride, 15mL ethanol was added for wet ball milling. The resulting mixture was dried in an oven at 120°C and calcined at 700°C in oxygen for 5 hours to obtain LiNi 0.6 co 0.2 mn 0.2 o 2 and Li 0.82 Ni 0.85 co 0.15 o 1.99 f 0.02 A composite positive electrode material, wherein the mass fraction of the high-nickel lithium-containing oxide in the composite material is about 9%, and the particle size of the high-nickel lithium-containing oxide is less than 100nm. Such as figure 2As shown, the spherical particles in the figure are the improved morphology, and the small particles on the surface are the morphology of the hig...

Embodiment 2

[0042] Following Example 1, except that lithium fluoride is not added, the amount of lithium hydroxide added is changed to 0.082mol, and the chemical formula of the high-nickel lithium-containing oxide in the obtained compound is Li 0.82 Ni 0.85 co 0.15 o 2 . The obtained composite material was assembled into a half-battery as a working electrode, and the battery was charged and discharged. The voltage range was 2.8-4.25V. The charge-discharge curve in the first week was tested at 0.1C / 0.1C, and the cycle capacity retention rate was tested at 1C / 1C.

Embodiment 3

[0044] Follow Example 1, just change the amount of lithium hydroxide added to 0.072mol, and the amount of lithium fluoride to 0.01mol, and the chemical formula of the high-nickel lithium-containing oxide in the obtained compound is Li 0.82 Ni 0.85 co 0.15 o 1.95 f 0.1 . The obtained composite material was assembled into a half-battery as a working electrode, and the battery was charged and discharged. The voltage range was 2.8-4.25V. The charge-discharge curve in the first week was tested at 0.1C / 0.1C, and the cycle capacity retention rate was tested at 1C / 1C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com