Diffusion pump capable of achieving rapid starting, floating heating and rotating injection

A fast-start, heating and rotating technology, applied in the field of diffusion pumps, can solve the problems of uneven heating, slow heating rate of pump oil, increase operating costs, etc., to reduce heating power and heating time, shorten startup time, and reduce operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

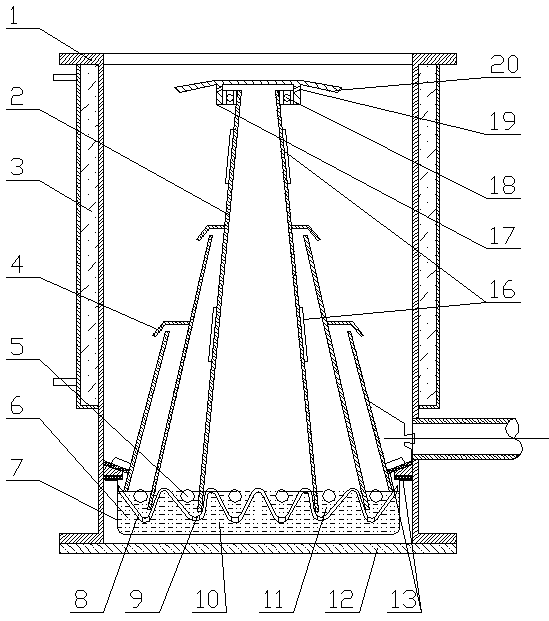

[0027] Embodiment 1: The embodiment of a kind of diffusion pump of floating heating rotary injection of the present invention is as follows figure 1 As shown, the basic structure includes: pump body 1, pump core 2, cooling system 3, injection system 4, pump oil 6, evaporation system 7 and control system, pump core 2 is equipped with a heating device 16, and injection system 4 adopts a rotary Spray head, rotary spray head 17 is installed on the upper end of steam conduit through bearing 18, can install one or several, blade 20 can also be installed on the rotary spray head 17, to further improve the performance of diffusion pump; Cooling system 3, pump oil 6 and control system Basically the same as the prior art, the pump body 1 can be divided into straight cavity and convex cavity. For the convenience of assembly, the bottom of the pump body 1 can be provided with a movable bottom plate 12; Heat insulation is installed inside the pump body 1. The outer surface of the evaporati...

Embodiment 2

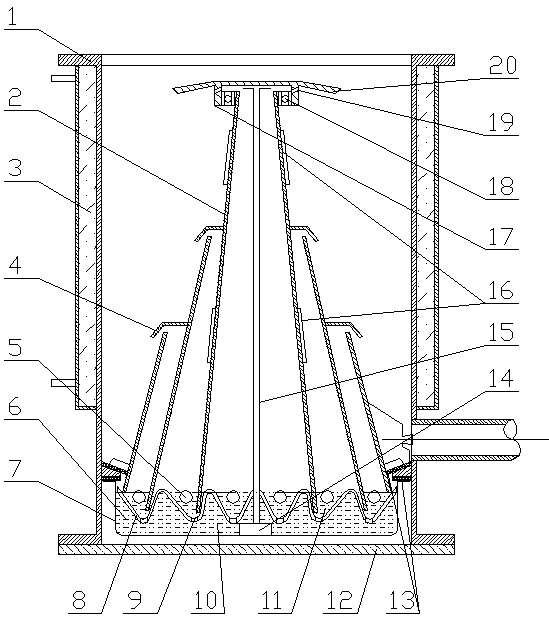

[0032] Embodiment 2: Another embodiment of the diffusion pump of the present invention with quick start floating heating rotary jet is as follows figure 2 As shown, compared with Embodiment 1, a submersible pump 14 and an oil pipe 15 are added in the oil storage area 10; the submersible pump 14 is connected with the oil pipe 15, and the top of the oil pipe 15 is located at the nozzle of the primary injection system; the diffusion pump stops When vacuuming, first turn off the vacuum valve and the power supply of the evaporation system 7, the heater 5 and the heating device 16 stop heating, then turn on the submersible pump 14, the pump oil 6 in the oil storage area 10 is injected at the nozzle through the oil pipe 15, and a part of the pump The oil 6 is sprayed onto the inner wall of the pump body 1 and cooled by the cooling system 3. Another part of the pump oil 6 is sprayed on the pump core 2 to cool the pump core 2. The pump oil 6 cooled by the cooling system 3 and the The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com