Commercial kitchen modular kitchen waste centralized dehydration and oil-removing system

A kitchen waste, modular technology, applied in the direction of grease/oily substance/float removal device, liquid separation, solid waste removal, etc., to achieve the effect of increasing sanitation level, reducing equipment investment and operating costs, and efficient nearby treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

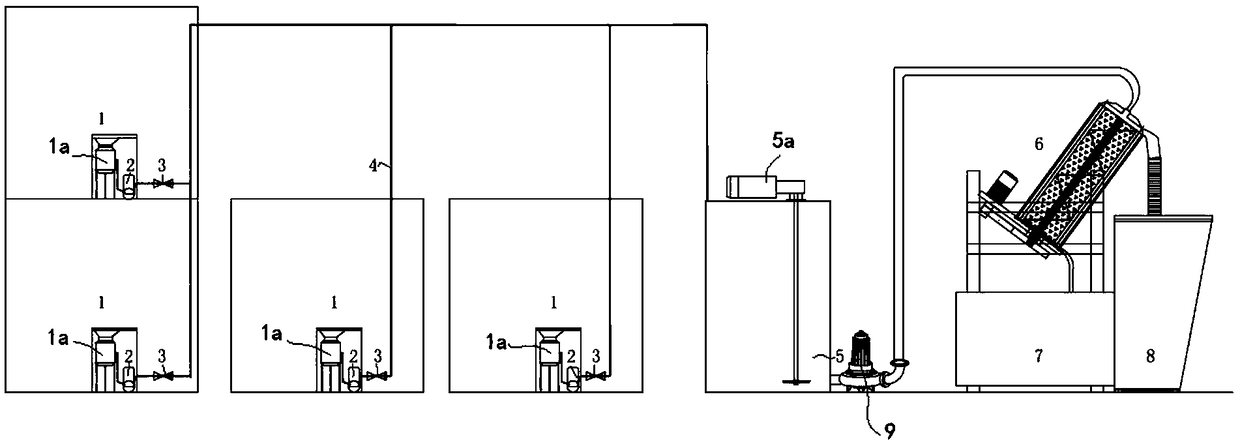

[0019] see figure 1 , a commercial kitchen modular food waste centralized dehydration and oil separation system shown in the figure, including a number of food waste collection stations distributed on different food waste collection points of commercial kitchen cabinets 1, at least one food waste temporary storage tank 5 , at least one dehydration unit 6 , at least one oil-water separator 7 , and at least one trash can 8 .

[0020] Each food waste collection station 1 includes at least one food waste grinder 1a, and each food waste grinder 1a has a waste water discharge port containing food waste. The kitchen waste collection station 1 among the present invention can be arranged in different places and different floors of commercial kitchens.

[0021] Each food waste temporary storage tank 5 has a waste water feed port containing food waste and a waste water discharge port containing food waste; in addition, each food waste temporary storage tank 5 is provided with a stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com