A silicon carbide mosfet drive circuit

A drive circuit, silicon carbide technology, applied in electronic switches, electrical components, high-efficiency power electronic conversion, etc., can solve the problems of low upper limit of gate turn-on voltage, device gate breakdown damage, low gate turn-on voltage, etc., to achieve Effects of reducing crosstalk, increasing switching speed, and reducing switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

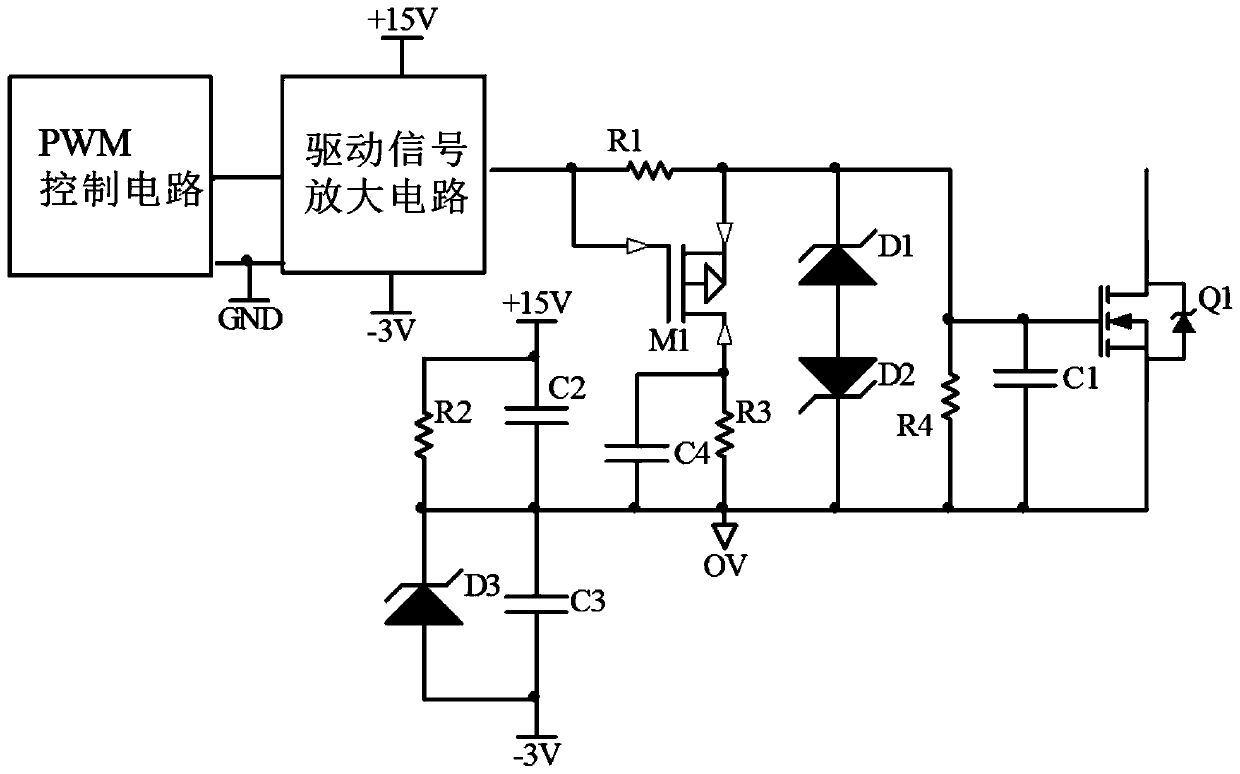

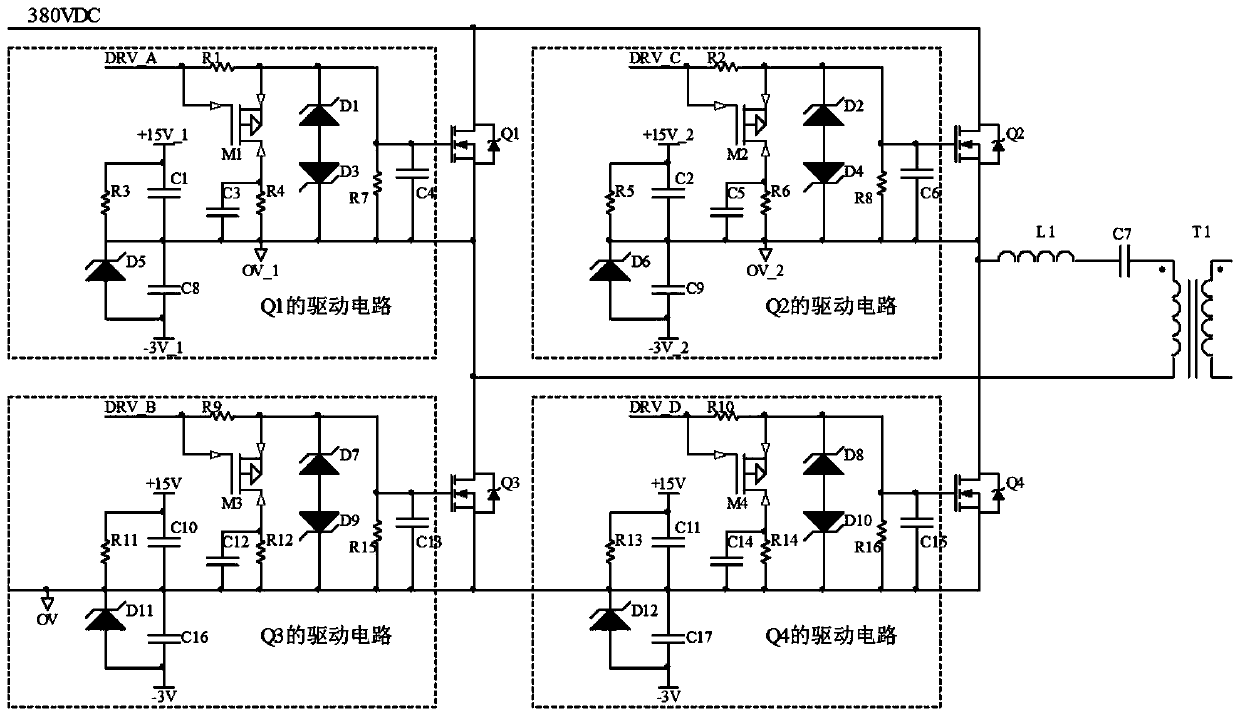

[0017] figure 1 It is the silicon carbide MOSFET driving circuit of the present invention.

[0018] The PWM control circuit generates a PWM pulse signal. After the PWM pulse signal passes through the driving signal amplifier circuit, the silicon carbide MOSFET switch is controlled through the resistor R1. The output of the power supply includes +15V, 0V and -3V DC voltage, and the +15V and -3V DC voltage are respectively given to The driving signal amplification circuit is powered, and 0V is connected to the source of the silicon carbide MOSFET (Q1).

[0019] The driving circuit of Q1 is composed of driving resistor R1, P-channel MOS tube M1, resistor R3, diodes D1, D2, resistor R4 and capacitors C1, C4, the output terminal of the driving signal amplifier circuit is connected with the driving resistor R1 and P-channel MOS tube M1 The gate of M1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com