A kind of rapid discharge device and discharge method of waste square battery

A prismatic battery and discharge device technology, applied in the direction of secondary battery charging/discharging, secondary battery, secondary battery maintenance/maintenance, etc. Liquid system and other problems, to achieve the effect of simple and easy discharge operation, avoid waste water and exhaust gas pollution, and speed up the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

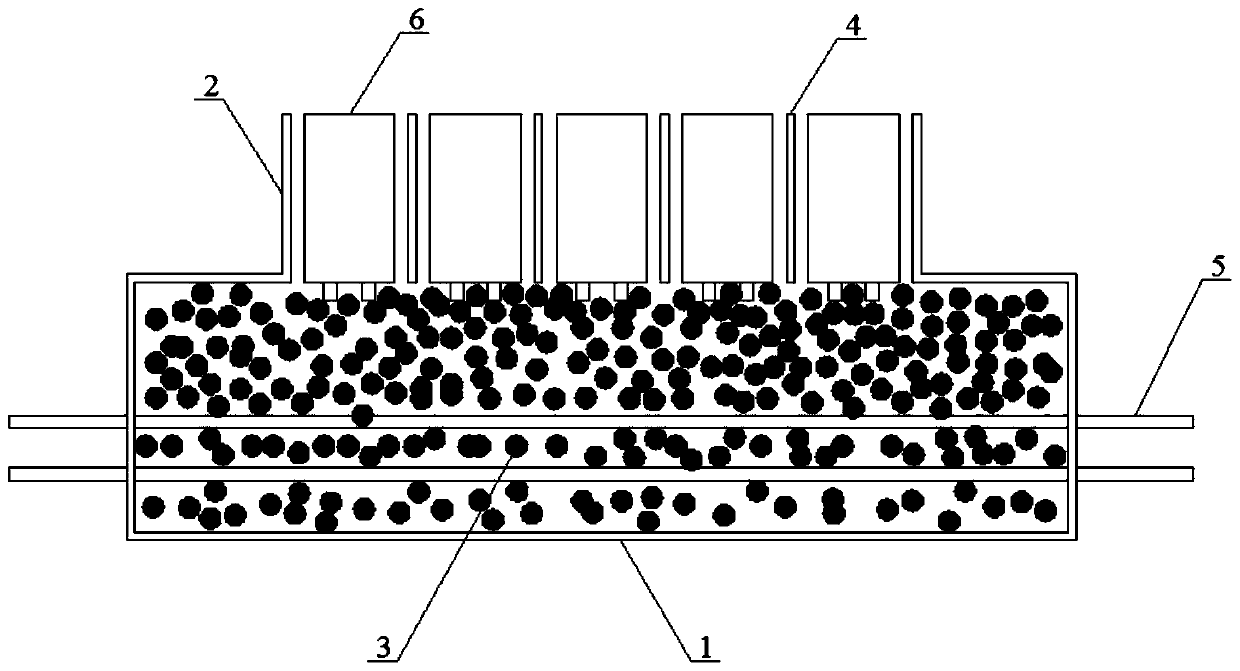

[0026] Such as figure 1 As shown, a rapid discharge device for waste square batteries is composed of a heat exchange tank 1 and a battery support 2 arranged above the heat exchange tank. The inside of the heat exchange tank is filled with metal conductive particles 3. The battery support is composed of multiple The battery is composed of a battery placement frame 4, the inverted battery pole is in contact with the metal conductive particles, and a heat exchange tube 5 is also arranged inside the heat exchange tank.

[0027] The heat exchange tube is made of aluminum, and the metal conductive particles are mixed with copper particles and aluminum particles with a mass ratio of 1:1. The particle size of the metal conductive particles is 0.35mm.

[0028] Using the above-mentioned discharge device to quickly discharge the waste square battery, put the waste square battery upside down in the battery placement frame, ensure that the pole of the battery is in contact with the metal c...

Embodiment 2

[0030] Such as figure 1 As shown, a rapid discharge device for waste square batteries is composed of a heat exchange tank 1 and a battery support 2 arranged above the heat exchange tank. The inside of the heat exchange tank is filled with metal conductive particles 3 and sand. The battery support is composed of multiple It is composed of a battery placement frame 4 for an inverted battery, and the inverted battery pole is in contact with metal conductive particles, and a heat exchange tube 5 is also provided inside the heat exchange tank.

[0031] The heat exchange tube is made of aluminum, and the metal conductive particles are mixed with copper particles and aluminum particles with a mass ratio of 1:1. The particle size of the metal conductive particles is 0.35mm. The mass ratio of metal conductive particles to sand is 1:0.05, and the particle size of the sand is 0.35mm.

[0032] Using the above-mentioned discharge device to quickly discharge the waste square battery, put t...

Embodiment 3

[0034] Such as figure 1 As shown, a rapid discharge device for waste square batteries is composed of a heat exchange tank 1 and a battery support 2 arranged above the heat exchange tank. The heat exchange tank is filled with metal conductive particles 3 and conductive agents. The battery support is composed of multiple A battery placement frame 4 for an inverted battery is formed. The inverted battery pole is in contact with metal conductive particles, and a heat exchange tube 5 is also provided inside the heat exchange tank.

[0035] The heat exchange tube is made of aluminum, and the metal conductive particles are mixed with copper particles and aluminum particles with a mass ratio of 1:1. The particle size of the metal conductive particles is 0.35mm. The mass ratio of the metal conductive particles to the conductive agent is 1:0.05, and the fiber diameter of the conductive agent is 150nm.

[0036] Preparation of conductive agent: first add 10g nano-carbon fiber into 50g sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com