Preparation method of gypsum scanning electron microscope sample

A scanning electron microscope and gypsum technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to prepare gypsum samples well, not being able to obtain high-quality microcrystalline morphology photos, and not being able to obtain sizes, etc., to achieve Good electrical conductivity, uniform thickness, fast sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method for a gypsum scanning electron microscope sample, comprising the steps of:

[0054] 1) Mix water and building gypsum powder of no less than 200 meshes, the ratio of mixture to water is 100:55, and stir quickly to form a uniform slurry. The stirring time is 1min. The slurry is viscous but can flow.

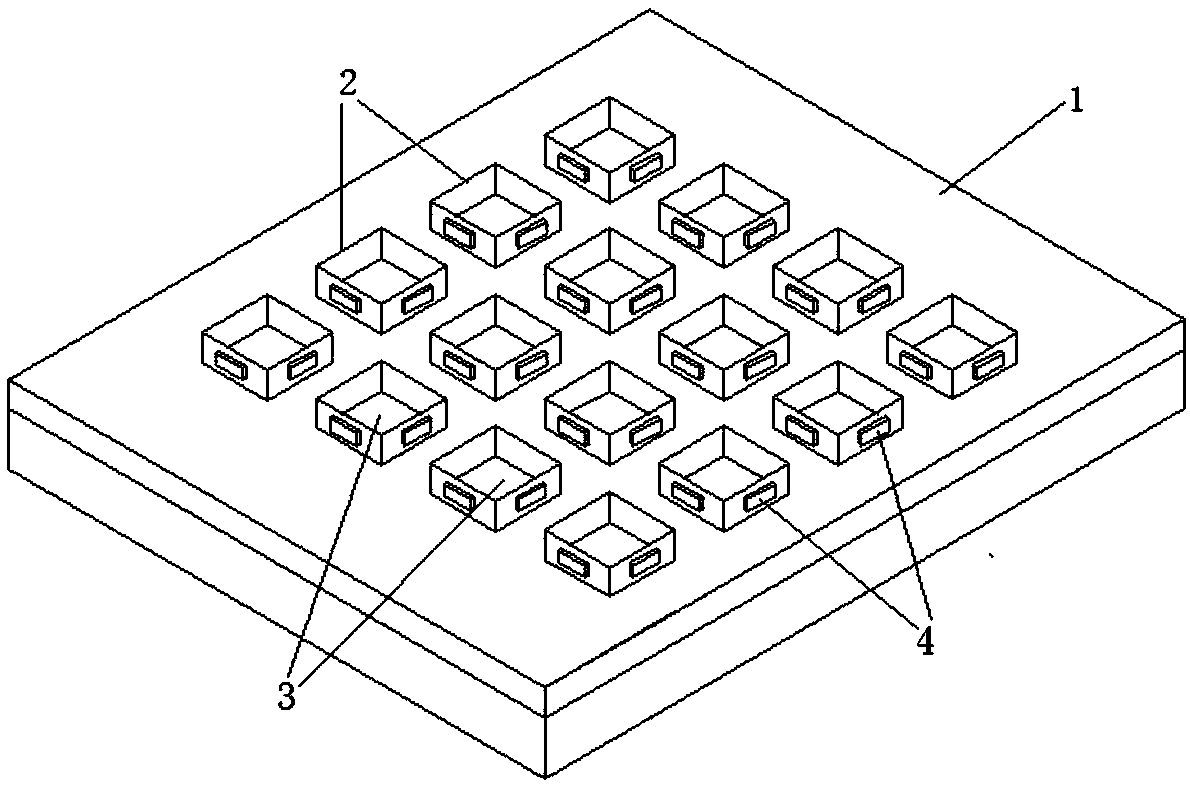

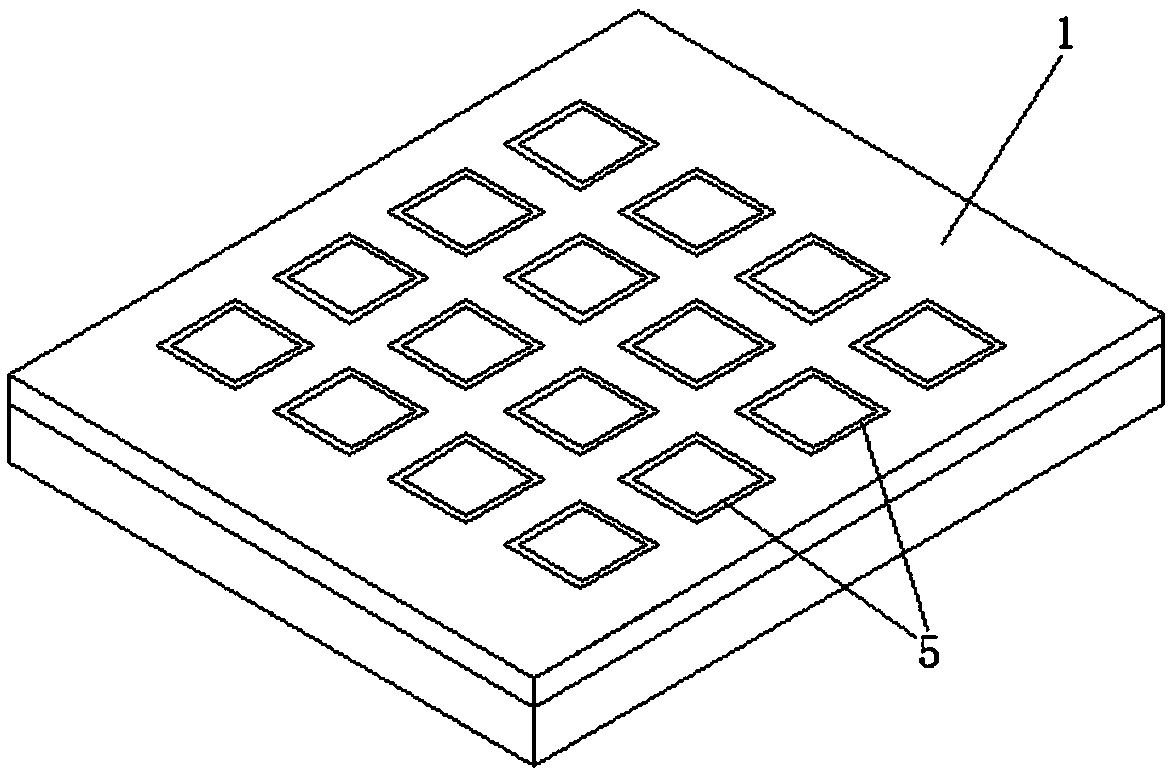

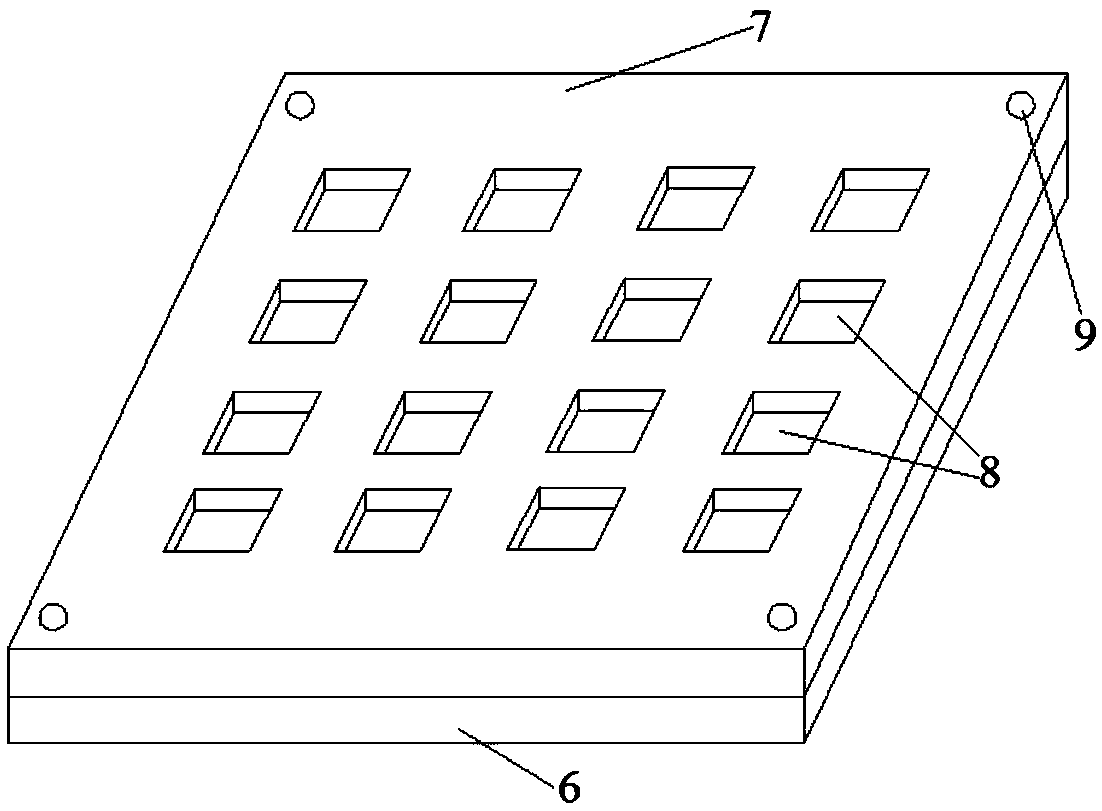

[0055] 2) Pour the slurry in step 1) into the cavity of the mold used to prepare the gypsum scanning electron microscope sample, scrape it flat, dry it at 25°C for 2 hours, and demould after molding to obtain a flaky gypsum sample; Mold such as figure 1 with 2 As shown, it includes a base plate 1, a baffle plate 2, a handle 4, and a draw slot 5. There are 16 draw slots distributed on the base plate 1, and the width of the baffle plate 2 matches the width of the draw slot 5, so that the baffle plate 2 Can be tightly engaged in the card slot 5, the baffle plate 2 is engaged in the card slot 5 to form the inner cavity 3, the size of the inner cavity 3 is ...

Embodiment 2

[0061] A preparation method for a gypsum scanning electron microscope sample, comprising the steps of:

[0062] 1) Mix water with not less than 200 meshes of building gypsum and fly ash powder, the ratio of the mixture to water is 100:53, stir quickly to form a uniform slurry, the stirring time is 2min, the slurry is viscous but can flow ;

[0063] 2) Pour the slurry in step 1) into the cavity of the mold used to prepare the gypsum SEM sample, scrape it flat, dry it at 25°C for 3 hours, and demould after molding to obtain a thin slice of 5mm×5mm×1mm Shape gypsum sample; The mold that adopts is with embodiment 1.

[0064] 3) Curing the gypsum sample in step 2) in a curing box, the curing temperature is 22°C, the curing humidity is 95%, and the curing time is 28 days;

[0065] 4) Put the gypsum sample cured in step 3) into an oven for drying, the drying temperature is 45°C, and the drying time is 24 hours;

[0066] 5) Paste the conductive tape on the side of the cuboid alumin...

Embodiment 3

[0069] A preparation method for a gypsum scanning electron microscope sample, comprising the steps of:

[0070] 1) Mix water with not less than 200 meshes of building gypsum, cement, and silica fume powder. The ratio of the powder mixture to water is 100:52. Stir quickly to form a uniform slurry. The stirring time is 2 minutes, and the slurry is viscous. but can flow;

[0071] 2) Pour the slurry in step 1) into the cavity of the mold used to prepare the gypsum scanning electron microscope sample, scrape it flat, dry it at 25° C. for 2 hours, and demould after molding to obtain a thin sheet of gypsum sample; Mold is with embodiment 1.

[0072] 3) Curing the gypsum sample in step 2) in a curing box, the curing temperature is 22°C, the curing humidity is 95%, and the curing time is 28 days;

[0073] 4) Put the gypsum sample cured in step 3) into an oven for drying, the drying temperature is 45°C, and the drying time is 24 hours;

[0074] 5) Paste the conductive tape on the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com