A high pressure resistant low hysteresis brush seal structure with nozzles on the front baffle

A technology of hysteresis brush type and sealing structure, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem that the gap between the brush wire and the rotor cannot be well reduced or eliminated, and the application range of the brush type seal is limited. Problems such as limited pressure bearing capacity, to improve the dynamic characteristics of the rotor, reduce axial excessive bending and blowing effect, and improve the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following implementations are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

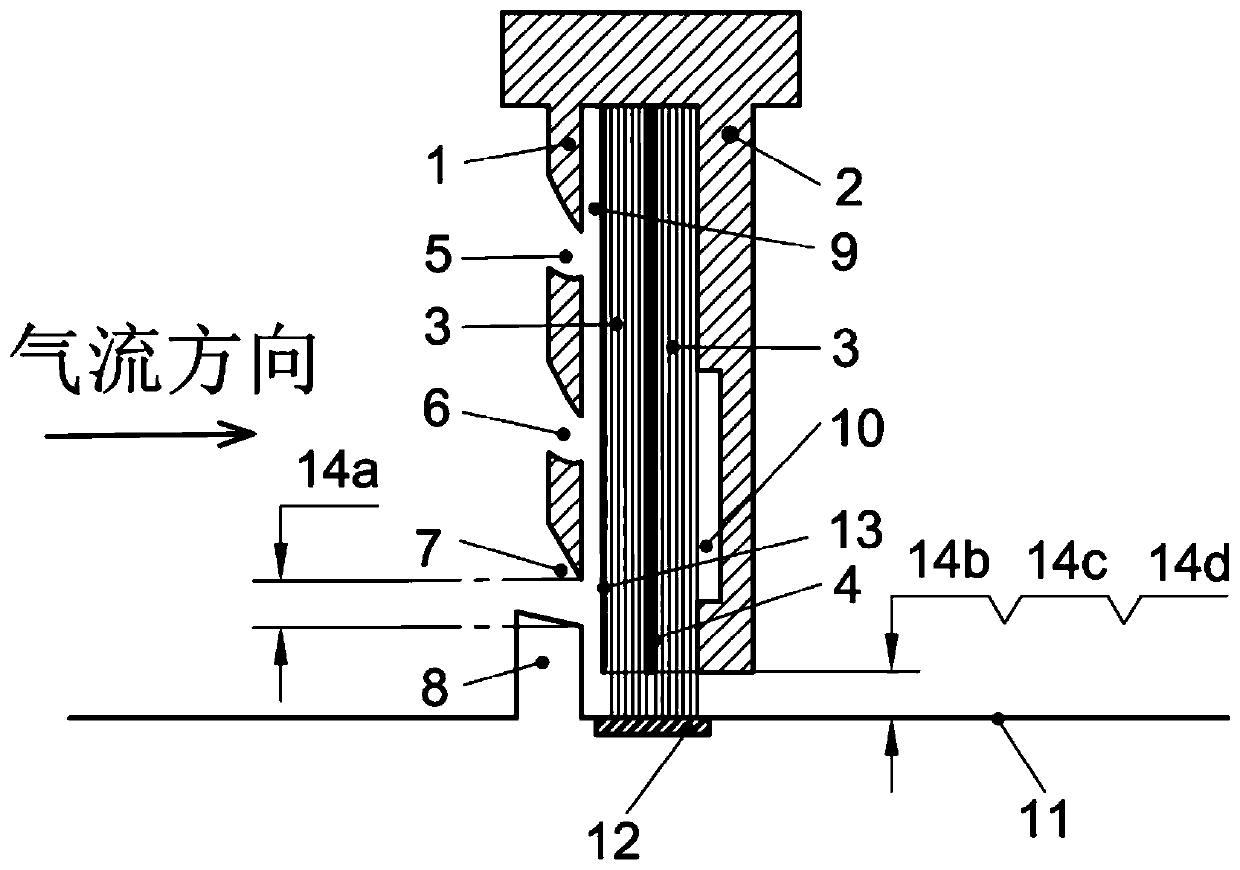

[0045] Concrete structure of the present invention sees appendix Figure 1-8 :

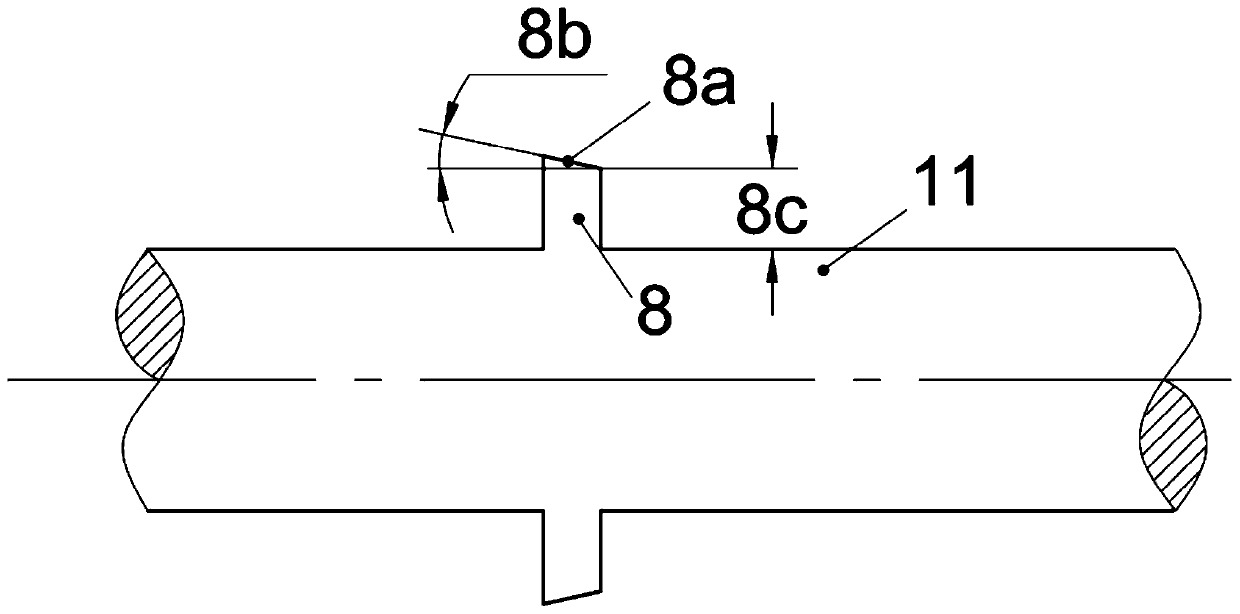

[0046] join figure 1 , The brush wire bundle 3 of the present invention is fixed between the front baffle 1 and the rear baffle 2 by fusion welding or MTU hooping process. The brush seal front baffle 1 is provided with a tangential-radial inclined first nozzle 5 and a second nozzle 6; the rotor 11 is provided with a rotor disk 8 near the front baffle 1, forming a diameter with the top of the front baffle 1. The third nozzle 7 is inclined; the contact area between the rotor 11 and the brush filament bundle 3 is provided with a smooth wear-resistant coating 12; there is a brush wire mesh 13 betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com