Spinning device with pressing ring capable of adjusting gap

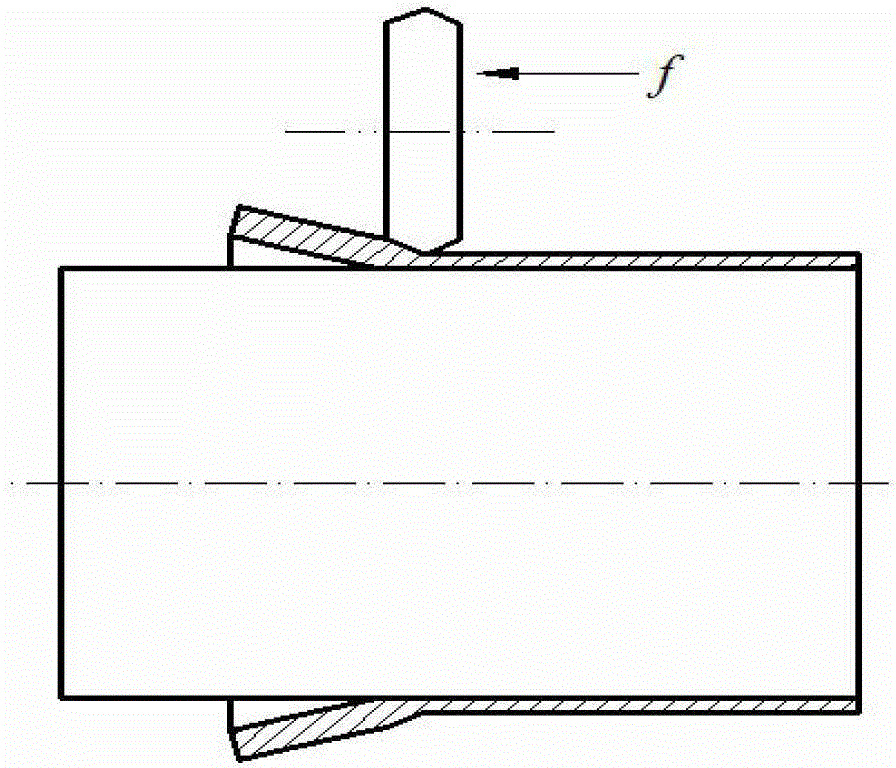

A gap adjustment and spinning wheel technology, which is applied in the field of spinning processing, can solve the problems of tail material instability, prolong production cycle, and low work efficiency, so as to improve material utilization, increase effective forming sections, and optimize contact status effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This implementation case is a device and method for suppressing the forward spinning of the bell mouth at the tail end of an aluminum alloy cylindrical part. The blank of the cylindrical part is an LF21M aluminum alloy pipe with an outer diameter of 265 mm, an inner diameter of 253 mm, a pipe wall thickness of 6 mm, and an axial length of 1000 mm. In the spinning process of this implementation case, the thickness reduction of the blank is 2 mm.

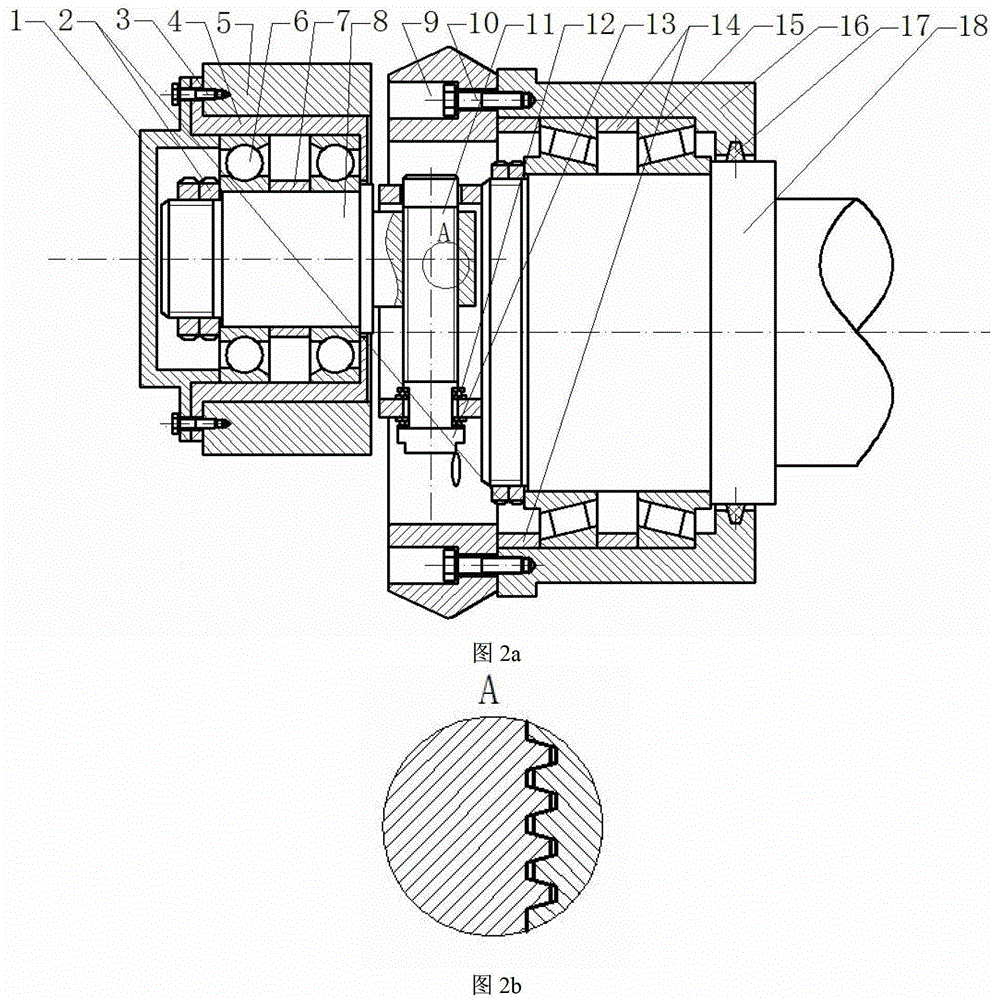

[0031] This embodiment includes a rotary wheel mandrel 18, a rotating body 16, a rotary wheel 9, a roller bearing 15, a bearing positioning sleeve 14, a screw pair, a pressure ring shaft 8, a pressure ring 5, a fixed sleeve 4, an angular contact bearing 6, a sleeve barrel 7 and bearing cover 1, and:

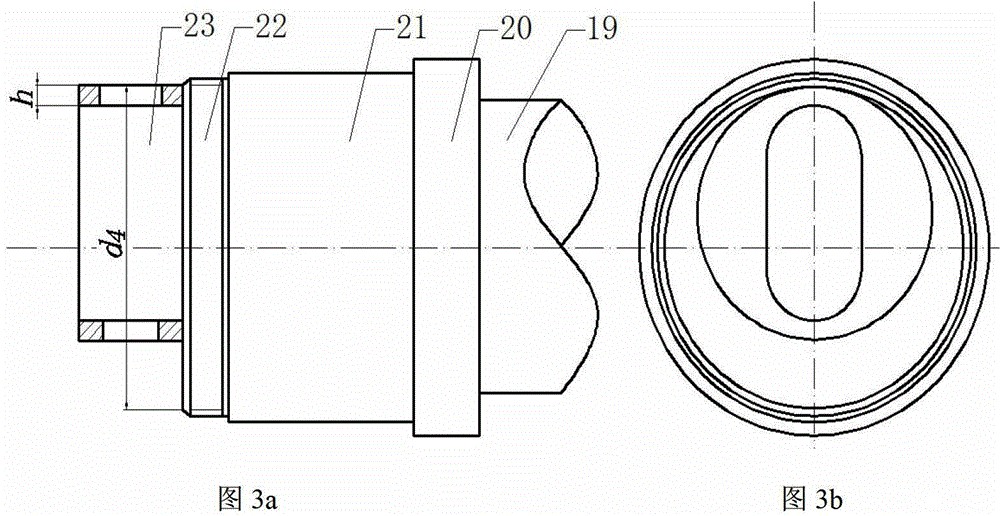

[0032] The rotary wheel mandrel 18 is a five-stage stepped shaft, which are respectively: the first stage shaft 19 of the rotary wheel mandrel for installing the rotary wheel seat feed mechanism, and the rotary wheel core for ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com