Full-automatic waterproof mountain-near granary for storing bulk grains

A fully automatic, warehouse-based technology, applied in the field of Yishan warehouses, can solve the problems of high waterproof requirements, grain mold and deterioration, and large floor space, and achieve the effects of optimizing force transmission channels, stabilizing two-way support, and increasing grain loading height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

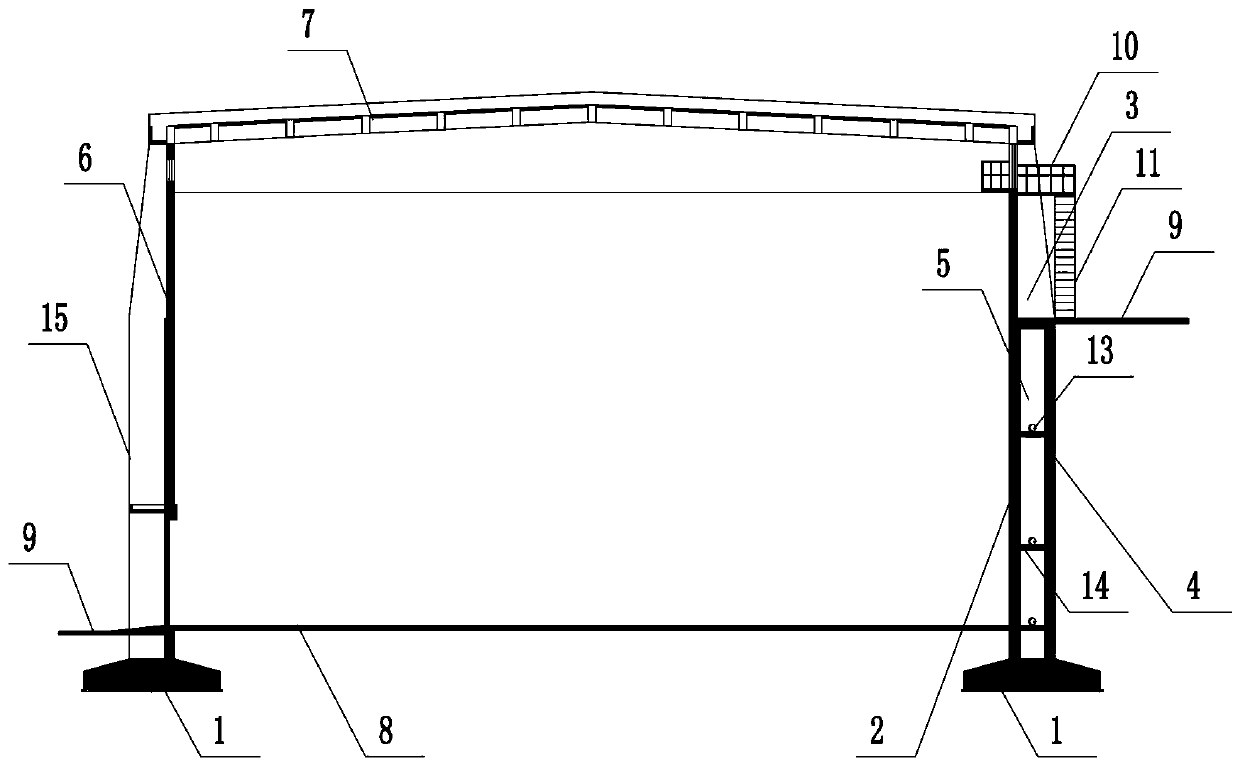

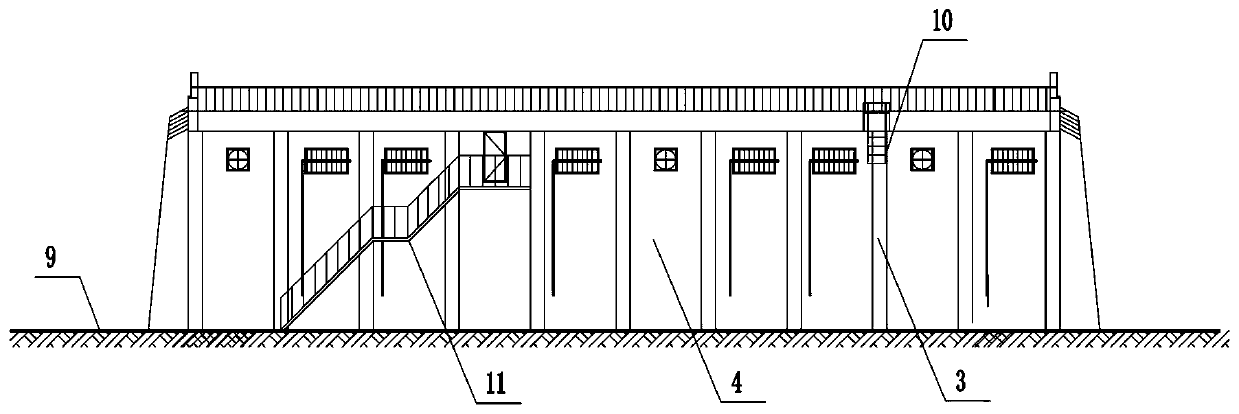

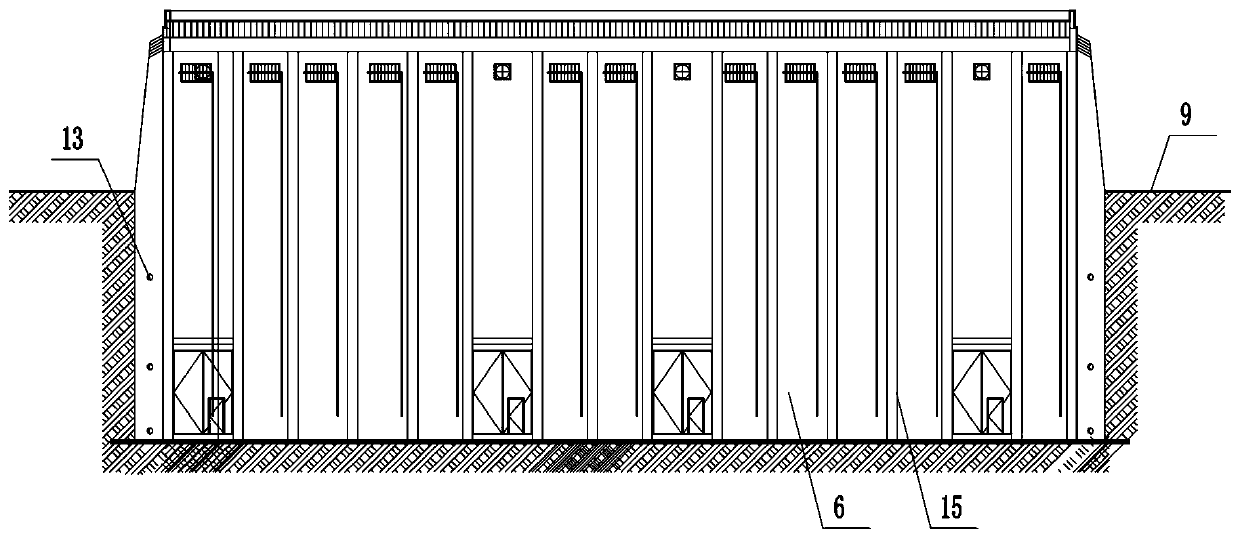

[0041] Such as Figure 1 to Figure 5 As shown, the present invention is a reinforced concrete structure, including a warehouse base 1, a warehouse bottom 8, a warehouse body and a warehouse roof 7, and the warehouse body includes a mountain-side warehouse body and an empty warehouse body, and the mountain-side warehouse body includes a plurality of mountain-side columns 3, Set up a gable wall between adjacent columns facing the mountain. The gable wall includes the outer wall 4 and the inner wall 2. The outer wall of the outer wall 4 is provided with a waterproof layer. The waterproof layer is made of polymer modified bitumen waterproof membrane. The inner wall 2 and the outer wall 4 Preset the cavity 5, a plurality of partition plates 14 are arranged in the cavity 5, and the partition plates 14 are sloped from the midpoint of the longitudinal length of the Linshan warehouse body to both sides according to the slope of 1°, and the water flow is set in the Linshan column. Chann...

Embodiment 2

[0043]The structure of this embodiment is the same as that of Embodiment 1, the difference is: the upper end surface of the partition plate 14 is provided with a waterproof coating (not shown in the figure), and the waterproof coating is made of asphalt. This structural design can prevent the problem of water seepage of the partition layer 14 , so that the water is enclosed in a separate structural stress community, and the waterproof effect is more effective.

Embodiment 3

[0045] The structure of this embodiment is the same as that of Embodiment 1, the difference is: as Figure 6 and Figure 7 As shown, the upper end surface of the partition plate 14 is an arc-shaped or stepped structure with an inner high outer bottom (the side close to the inner wall is inner, and the side closer to the outer wall is outer). This structure design is conducive to the collection of water near the outer The location of the wall prevents moisture and water seepage on the inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com