Double-waterproof composite roof

A compound and double technology, applied in the direction of roof, roof cladding, building roof, etc., can solve the problems of affecting the appearance of the roof, high water absorption rate, inconvenient maintenance, etc., to achieve good interface compatibility, low cost, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

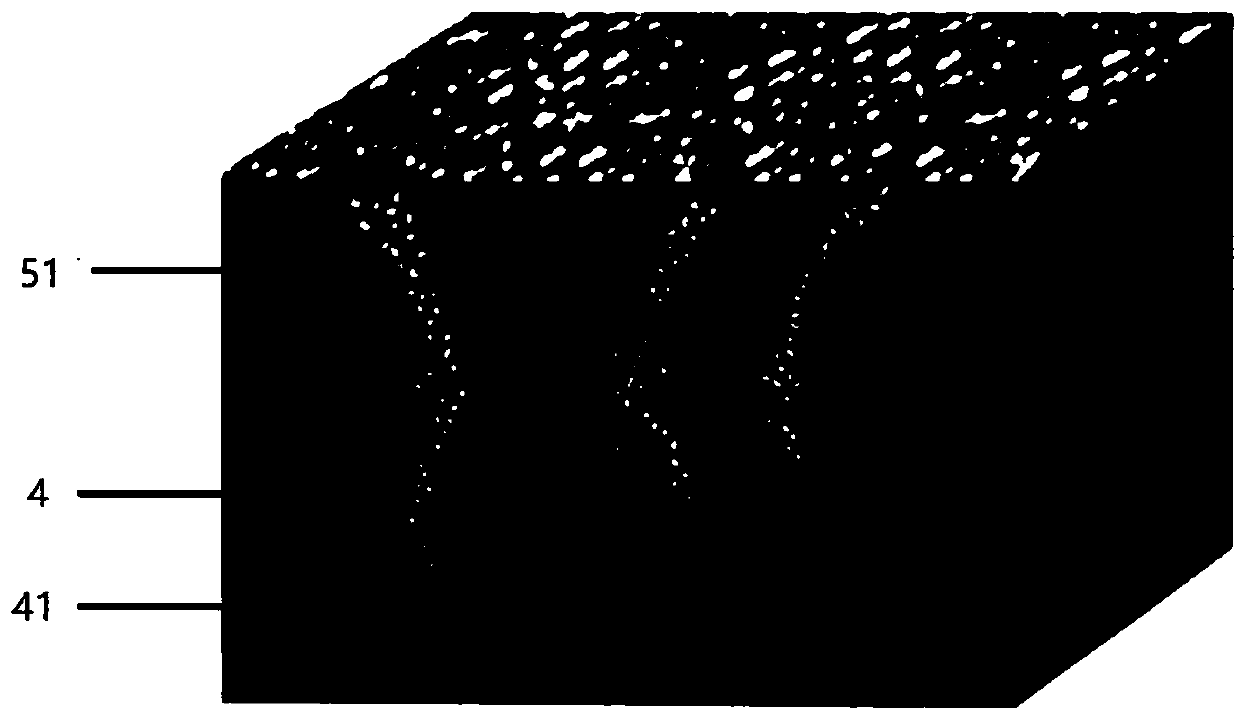

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. What the present invention discloses is a double waterproof composite roof, such as figure 1 As shown, it is a preferred embodiment of the present invention, comprising reinforced concrete panel 1, cement mortar leveling layer 2, flexible waterproof layer 3, foam concrete layer 4 and inorganic permeable crystalline waterproof mortar protective layer 5, reinforced concrete panel 1, cement The mortar leveling layer 2, the flexible waterproof layer 3, the foam concrete layer 4 and the inorganic permeable crystalline waterproof mortar protective layer 5 are tiled and superimposed in sequence. The present invention makes full use of the good thermal insulation capability of the foam concrete layer 4, and prepares the foam concrete layer 4 between the flexible waterproof layer 3 and the inorganic permeable crystalline waterproof mortar layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com