Preparation method for alternating frequency ultrasound coupling hot-pressing infiltration porous ceramic enhanced magnesium matrix composite material

A technology of porous ceramics and ultrasonic coupling, applied in the field of preparation of magnesium-based composite materials, can solve the problems of poor forming ability and low plasticity, achieve the effects of reducing casting defects, solving poor wettability, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

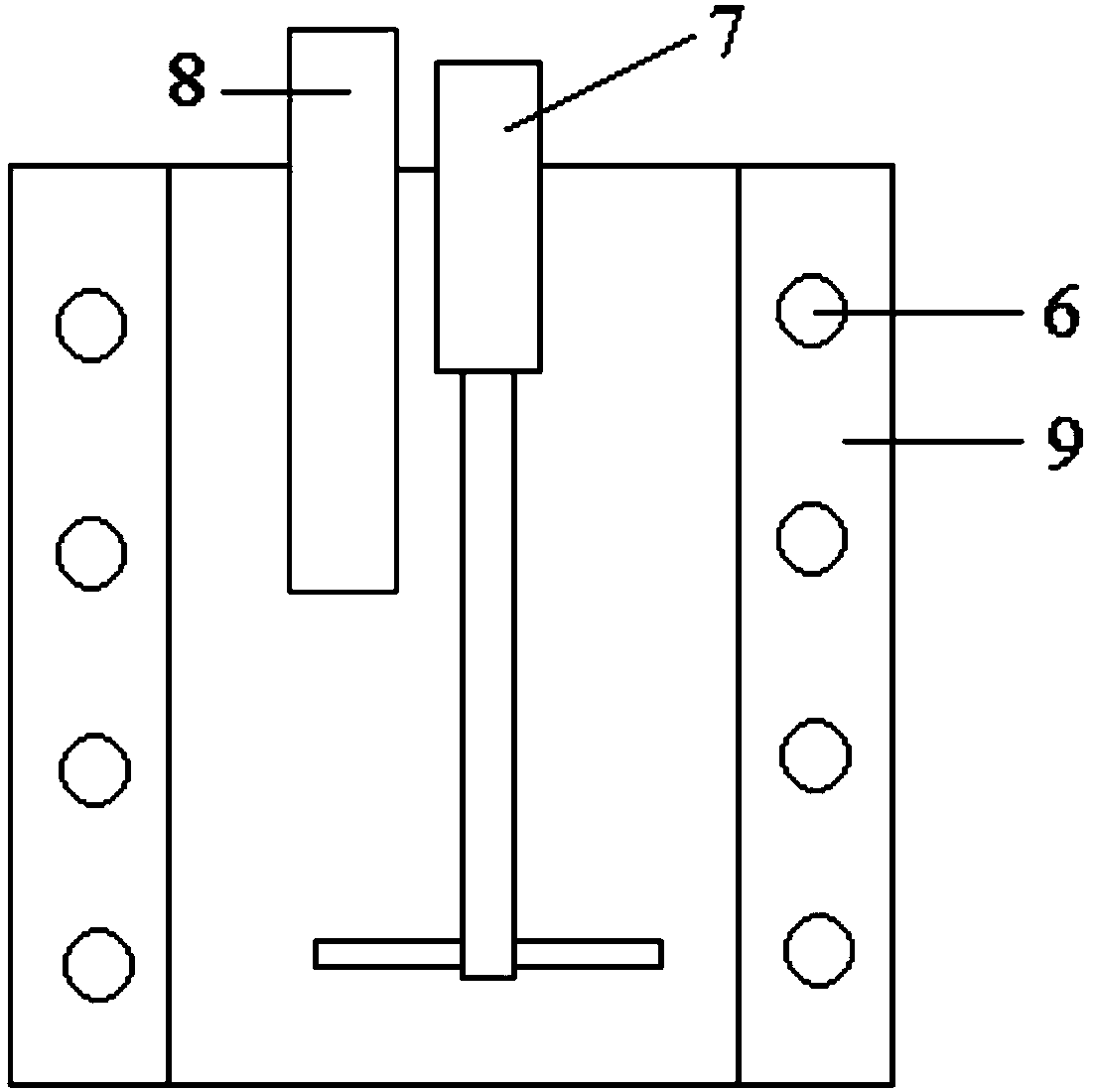

[0023] Specific implementation mode 1: This implementation mode is a preparation method of cross-frequency ultrasonic coupling hot-pressing impregnation porous ceramic reinforced magnesium-based composite material, which is carried out according to the following steps:

[0024] 1. Preparation of a porous ceramic-coated magnesium alloy melt combination: heat the porous ceramic powder to 400°C-600°C, then immerse the liquid magnesium alloy into the porous ceramic powder at 400°C-600°C, and then conduct cross-frequency ultrasound Coupled hot-press rapid prototyping, natural cooling to room temperature, to obtain a combination of porous ceramics coated with magnesium alloy melt;

[0025] The mass ratio of the porous ceramic powder at 400°C to 600°C to the liquid magnesium alloy is 1:(1.5 to 2);

[0026] The method for rapid prototyping of cross-frequency ultrasonic coupling hot pressing is as follows: the first-stage ultrasonic and hot pressing are carried out simultaneously under...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the porous ceramic powder described in step 1 is α-SiC porous ceramic powder and α-Al 2 o 3 One or a mixture of two porous ceramic powders; the particle size of the α-SiC porous ceramic powder is 50 μm to 300 μm, the pore size is 15 μm to 35 μm, and the porosity is 40% to 70%; the α– Al 2 o 3 The particle diameter of the porous ceramic powder is 30 μm-300 μm, the pore diameter is 15 μm-35 μm, and the porosity is 40%-70%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the liquid magnesium alloy described in step 1 is magnesium alloy AZ91. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com