Calcium and magnesium additive for improving coal slagging performance and application

An additive, calcium and magnesium technology, which is applied in the field of coal chemical industry, can solve the problems of large amount of addition and high economic cost of coal blending, and achieve the effects of improving slagging, avoiding furnace flameout accidents, and reducing boiler slag formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Add calcium carbide slag and ethyl maltol magnesium waste slag with different contents and fully ground to the high-sodium coal, wherein calcium hydroxide content in calcium carbide slag is 85%, and magnesium oxide content in ethyl maltol magnesium waste slag is 60% ; Since the activity of CaO is the highest at about 900°C-1000°C, and the activity of MgO reaches the maximum at 700°C, therefore, according to the temperature distribution above the combustion boiler, the nozzles for carbide slag, the nozzles for ethyl maltol magnesium-containing waste residue, and the nozzles for carbide slag and ethyl maltol The different injection temperature of base maltol magnesium-containing waste slag makes the activities of calcium carbide slag and ethyl maltol magnesium-containing waste slag reach the highest.

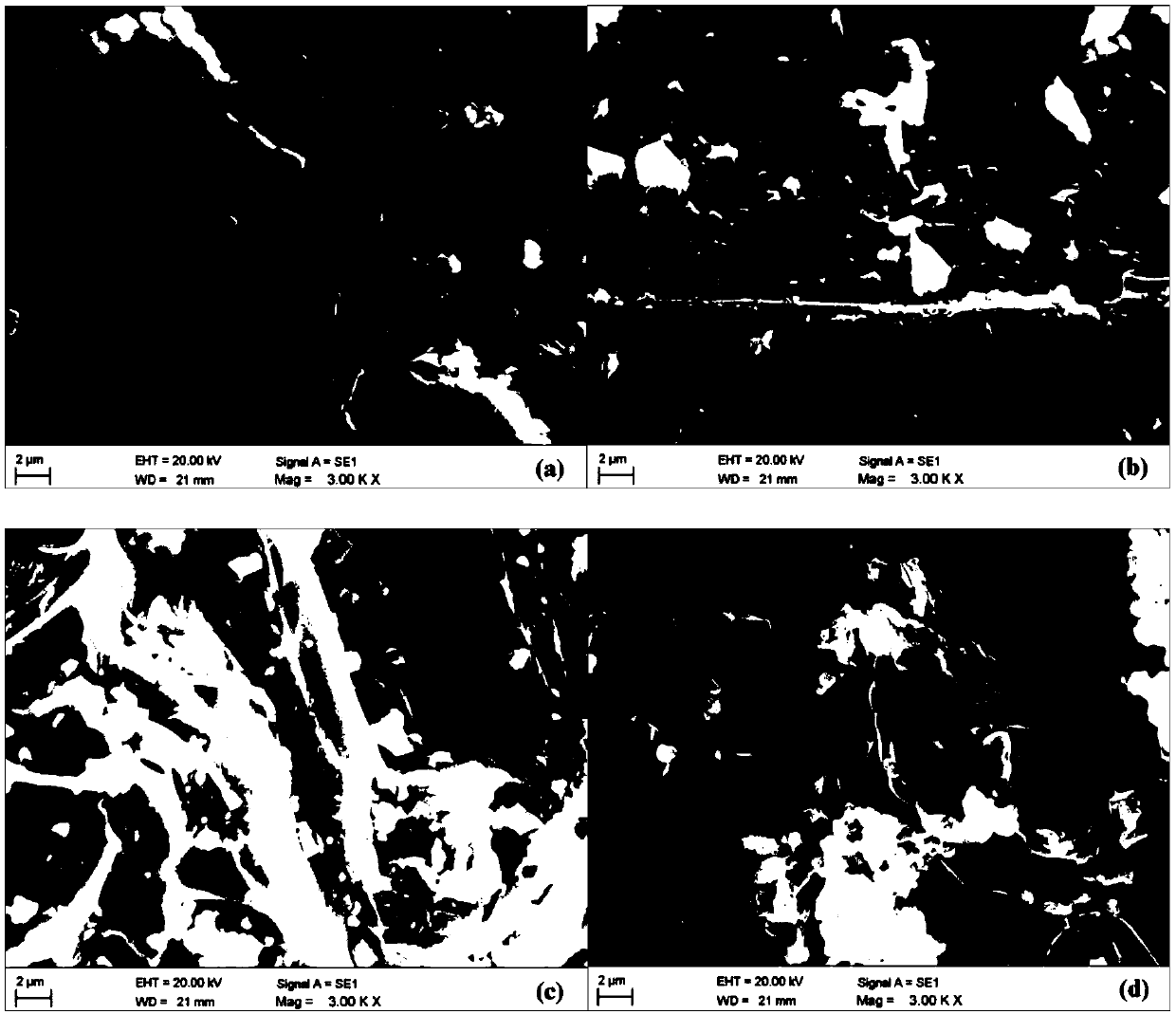

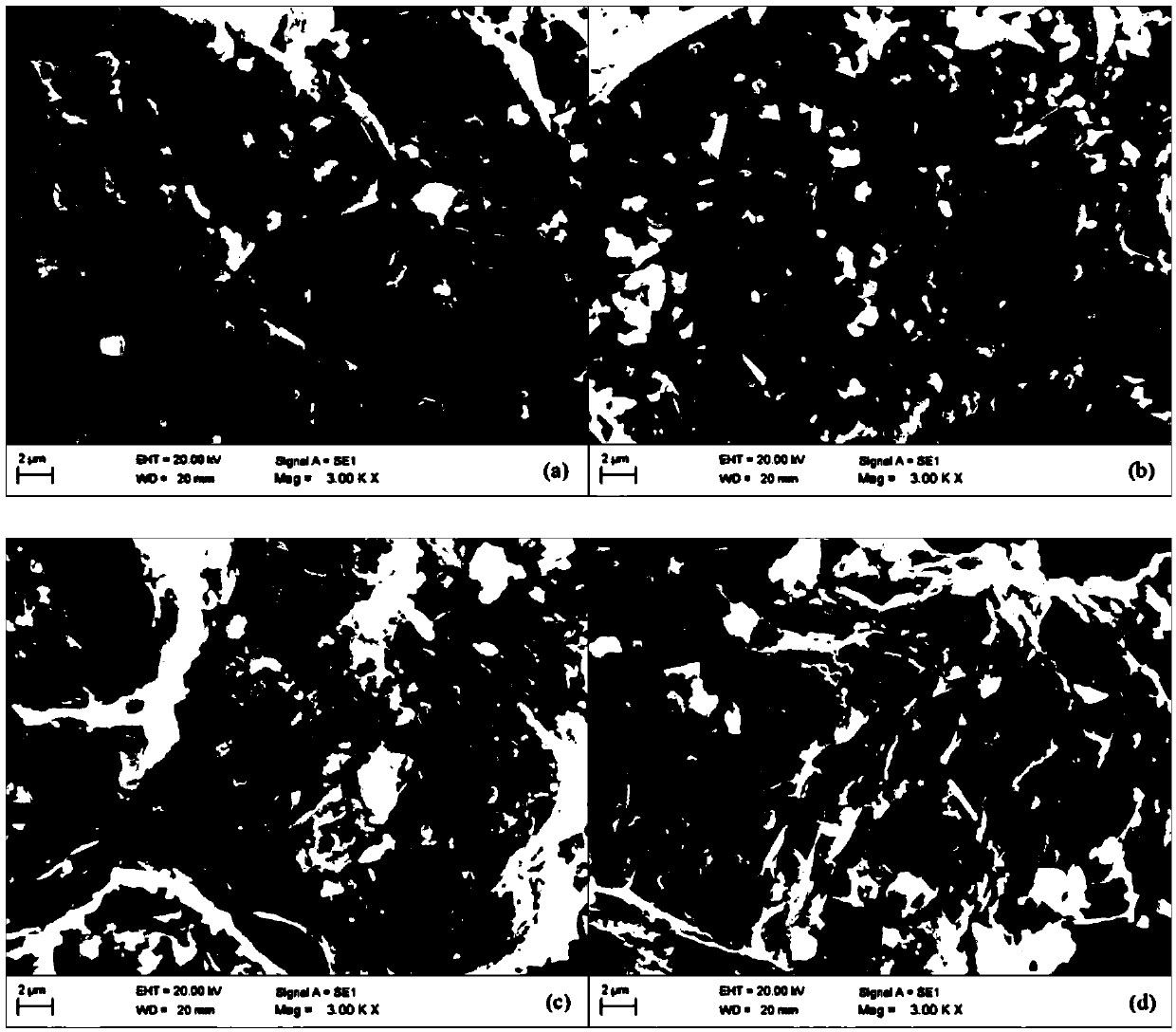

[0080] Add different contents of calcium carbide slag, and conduct SEM analysis on the coal ash obtained by burning at 1200°C, the results are as follows: figure 1 The data s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com