Fireproof composition for preparing fireproof glass and preparation method thereof

A technology for fireproof glass and composition, applied in the field of fireproof composition and preparation thereof, fireproof composition for fireproof glass and preparation thereof, can solve the problems of low adhesion of fireproof liquid, poor anti-aging performance, affecting fireproof performance and the like, To achieve the effect of improving adhesion, good fire resistance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

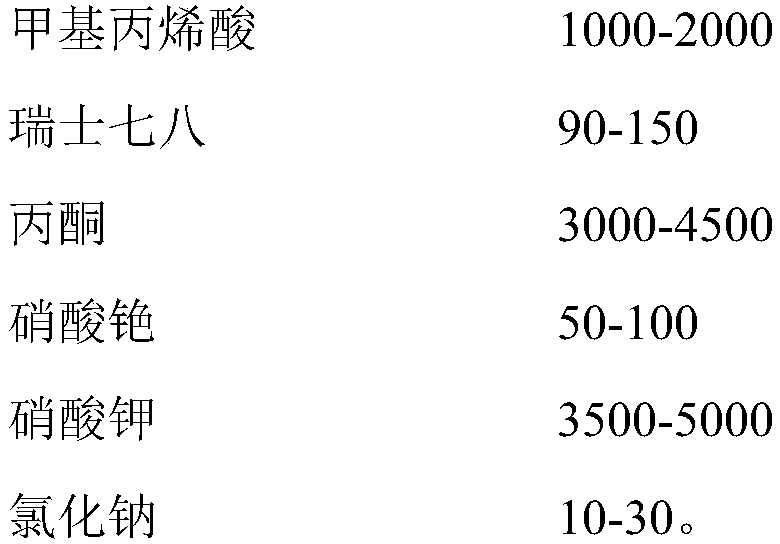

[0040] 1. Prepare raw materials according to the following weight ratio (g)

[0041]

[0042]

[0043] 2. Pour the raw materials potassium nitrate, cesium nitrate, Swiss seven-eight, methacrylic acid, acetone, and table salt into a plastic container filled with water in sequence, and use an electric stirrer to stir for mixing. The stirring rate is 120rpm (usually 60-120rpm); stirring time is 1.5h;

[0044] 3. Stir and mix the mixed solution for 1.5 hours, and place it at a temperature of 25°C to allow it to fully blend with each other, and leave it to react for 48 hours to obtain the fireproof composition of the present invention.

Embodiment 2

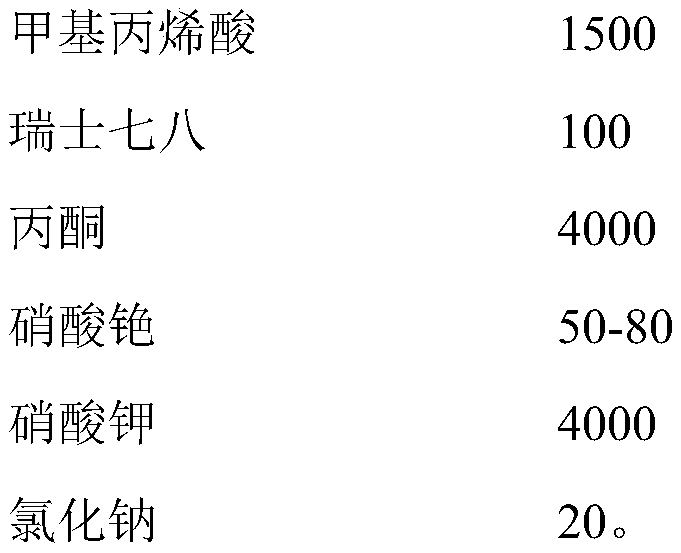

[0046] 1. Prepare raw materials according to the following weight ratio (g)

[0047]

[0048] 2. Pour the raw materials potassium nitrate, cesium nitrate, Swiss seven-eight, methacrylic acid, acetone, and salt into a plastic container filled with water in sequence, and use an electric stirrer to stir for mixing treatment, wherein the stirring rate is 100rpm (usually 60-120rpm); Stirring time is 2h;

[0049] 3. Stir and mix the mixed solution for 2 hours, and place it under the temperature condition of 25° C. to fully fuse with each other to generate oxidation and reduction reactions. After standing for 50 hours, the fireproof composition of the present invention is obtained.

Embodiment 3

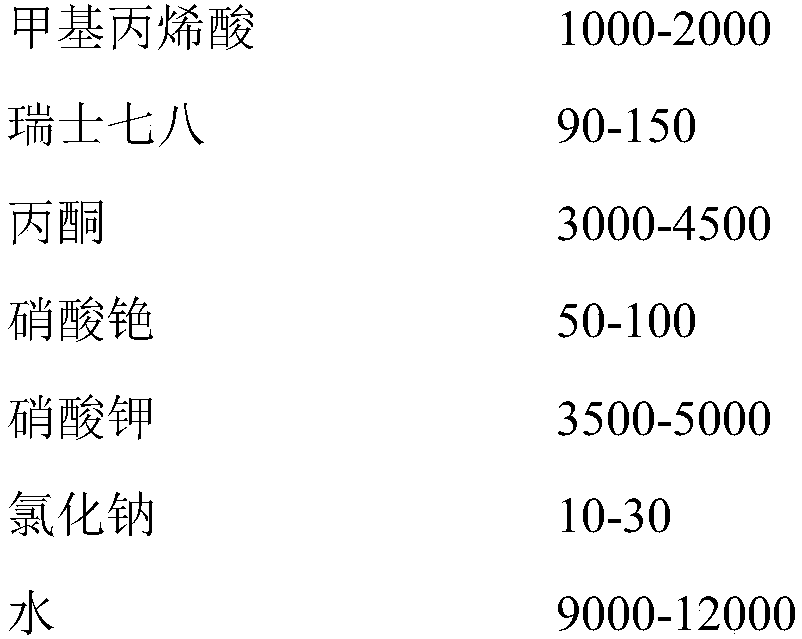

[0051] 1. Prepare raw materials according to the following weight ratio (g)

[0052]

[0053]

[0054] 2. Pour the raw materials potassium nitrate, cesium nitrate, Swiss seven-eight, methacrylic acid, acetone, and table salt into a plastic container filled with water in sequence, and use an electric stirrer to stir for mixing. The stirring rate is 60rpm (usually 60-120rpm); Stirring time is 2h;

[0055] 3. Stir and mix the mixed solution for 2 hours, and place it under the temperature condition of 25° C. to fully fuse with each other to generate oxidation and reduction reactions. After standing for 60 hours, the fireproof composition of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com