Wire press device for movable type wire coiling device

A technology of a wire crimping device and a wire reel, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc. Line quality, the effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

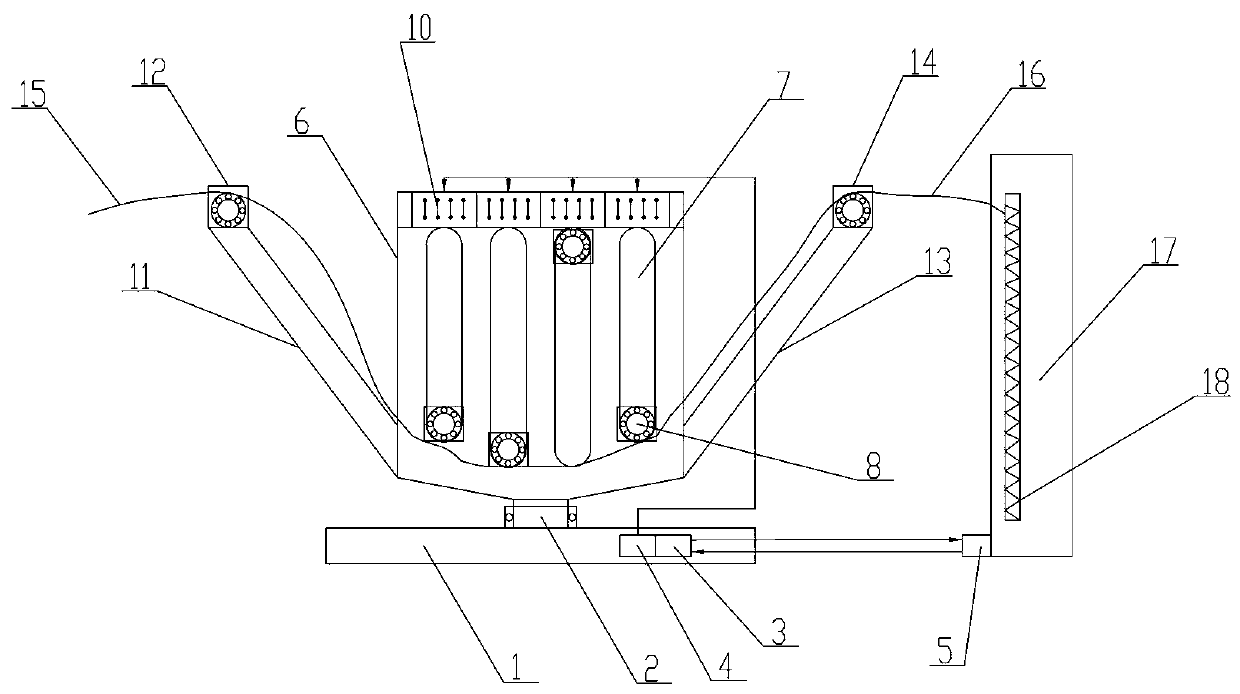

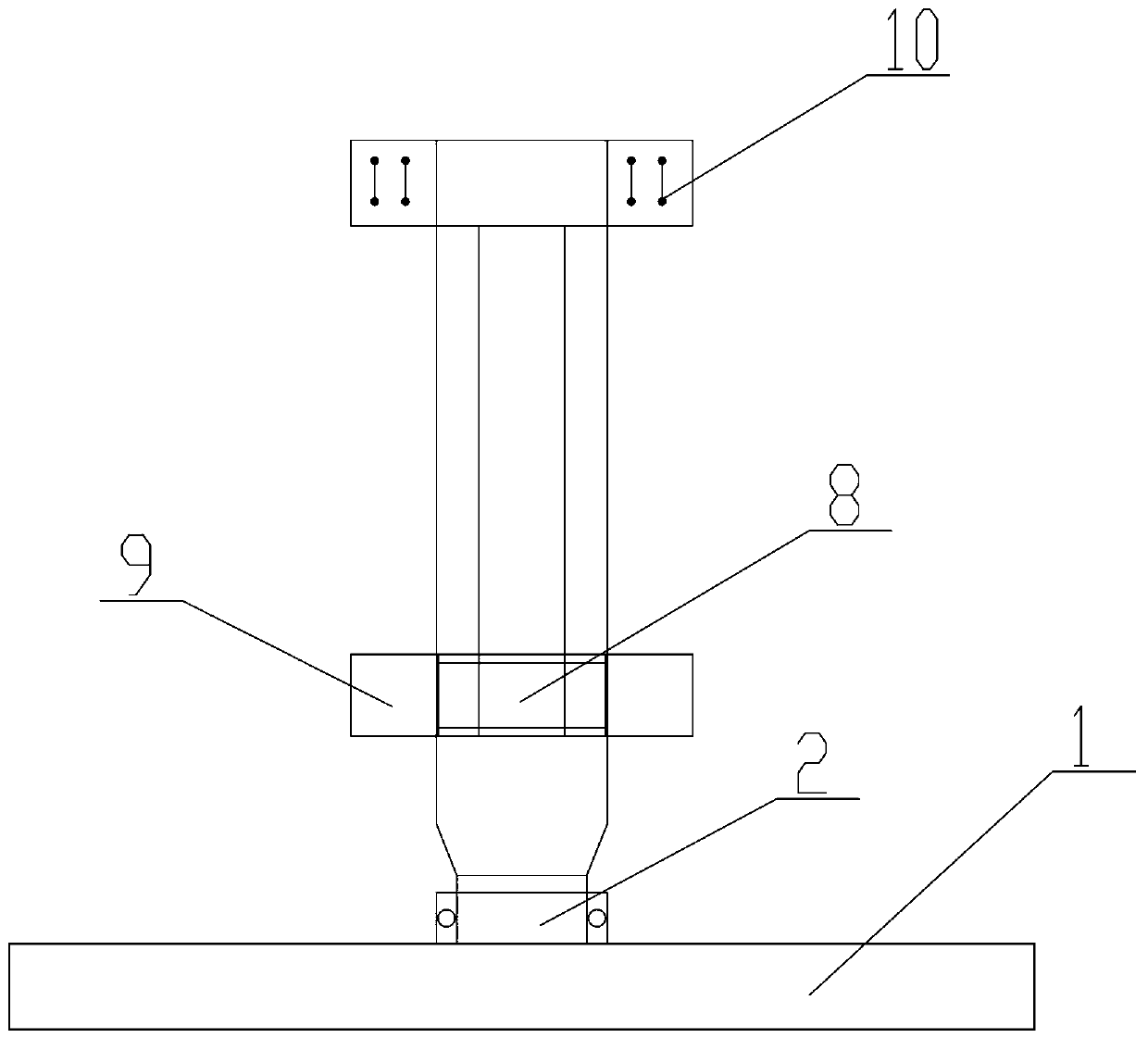

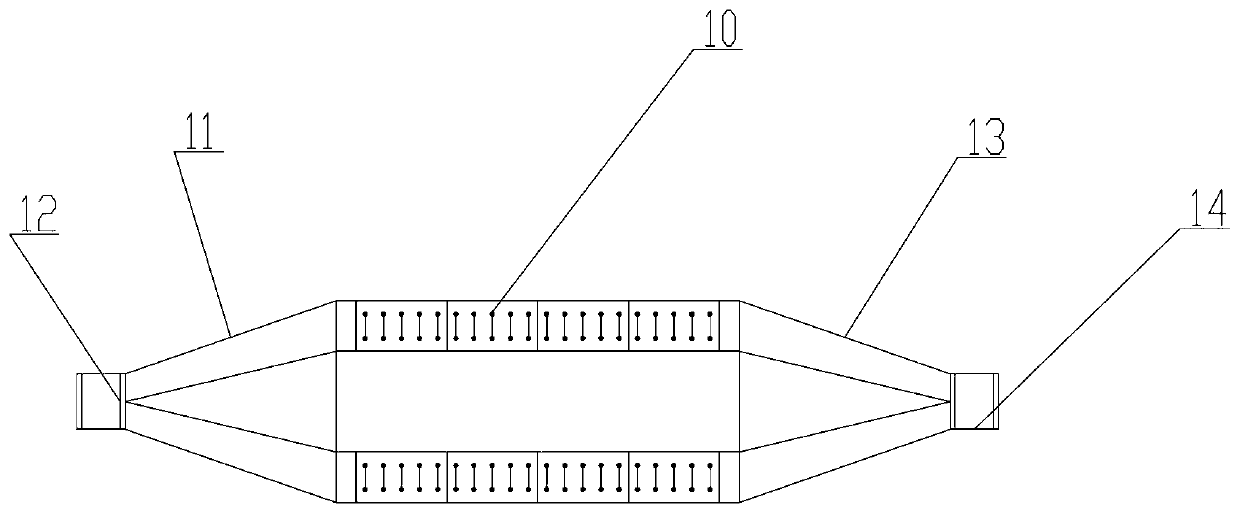

[0026] Figure 1~Figure 3 A schematic structural view of the wire crimping device of this embodiment is shown. The wire crimping device is fixed at one end of the prefabricated building mold table, and is used to connect the wire coiler. During the coiling process of the wire coiler, a certain pressure is applied to the power line (cable line), so that the cable line is in a tensioned state. Avoiding the phenomenon of wire harness slack when the distance between the mold table and the wire reel is relatively long, thereby avoiding the problem of wire bundle accumulation, and finally improving the wire reel quality of the wire reel.

[0027] like figure 1 As shown, the crimping device includes a base 1, the base 1 is fixed at one end of the mold table, the base 1 can be a square plate structure, and the crimping structure is fixed on the base 1, wherein the crimping structure includes a crimping structure body 6, and the crimping structure The longitudinal section of the wire...

Embodiment 2

[0036] The structure of the crimping device of this embodiment is the same as that of Embodiment 1, the difference is that the steering structure 2 is a linear motion mechanism, such as Figure 5 As shown, the linear motion mechanism includes a guide shaft 19, the guide shaft 19 is fixed on the guide shaft support 20, a linear bearing 21 is fixed on the guide shaft 19, a fixed plate 21 is installed on the linear bearing 21, and the fixed plate 21 is used to connect the crimping structure The bottom of the body 6. The linear bearing 21 is connected with an external motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com