Single-sided surface layer compressed wood and preparation method thereof

A technology for compressing wood and surface layers, applied in lamination, lamination devices, wood compression, etc., to achieve the effects of uniform temperature distribution, improved flatness, energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

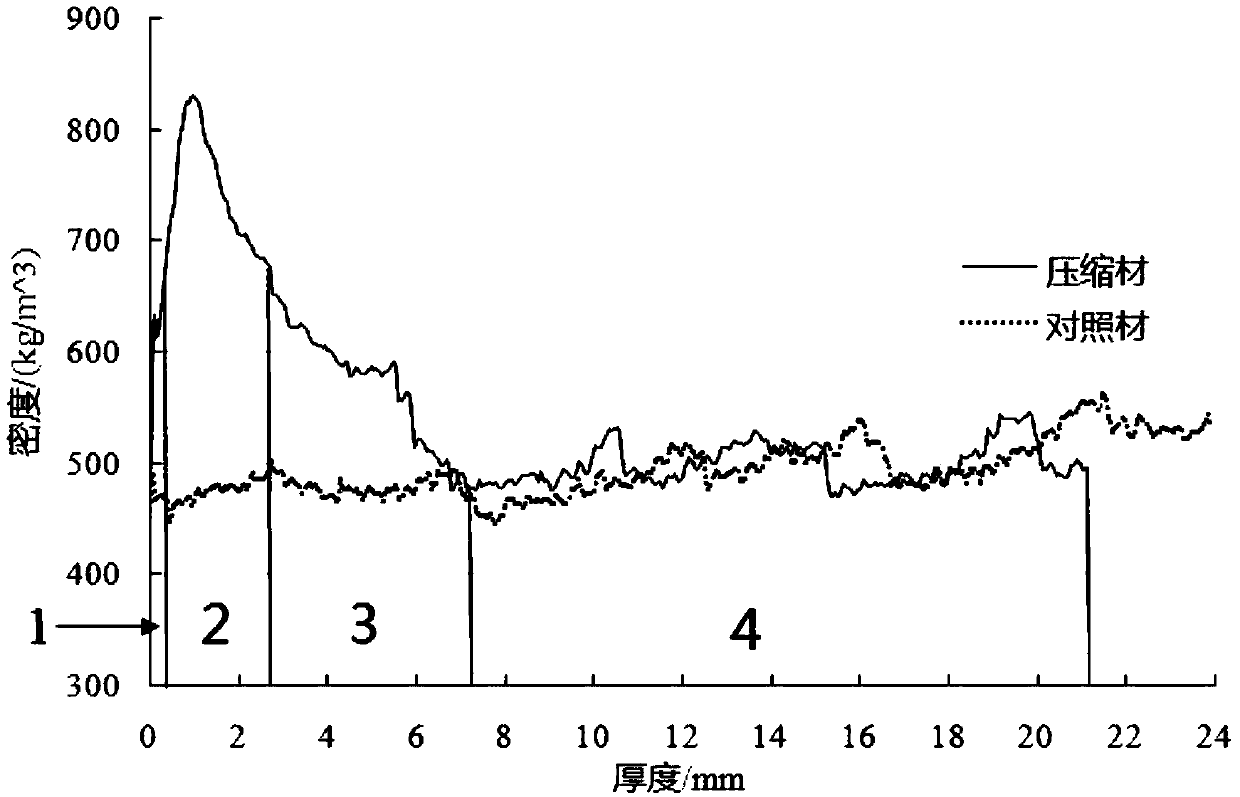

Embodiment 1

[0036] (1) Double-sided planing of the kiln-dried poplar wood with a moisture content of 12% is prepared into a board with a size of 820×122×24 mm;

[0037] (2) Turn on the hot press, raise the temperature of the upper and lower platens to 120°C, lay three pieces of poplar wood planed on both sides neatly in a single row on a 3 mm heat insulation lining board, and place the wood on both sides 21 mm thickness gauge, place the backing plate and wood together on the lower pressing plate that is preheated to the required temperature;

[0038] (3) close the press, make the hot plate on the press contact with the poplar wood upper surface, preheat 30 seconds;

[0039] (4) Set the pressure of the press to 6 MPa, compress the wood to the required thickness at a feed rate of 0.10 mm / s, and then hold the pressure for 100 seconds;

[0040] (5) Raise the temperature of the lower platen to 121°C, and the heating rate is 10°C / min;

[0041] (6) The pressure is reduced to 1 MPa, and this pr...

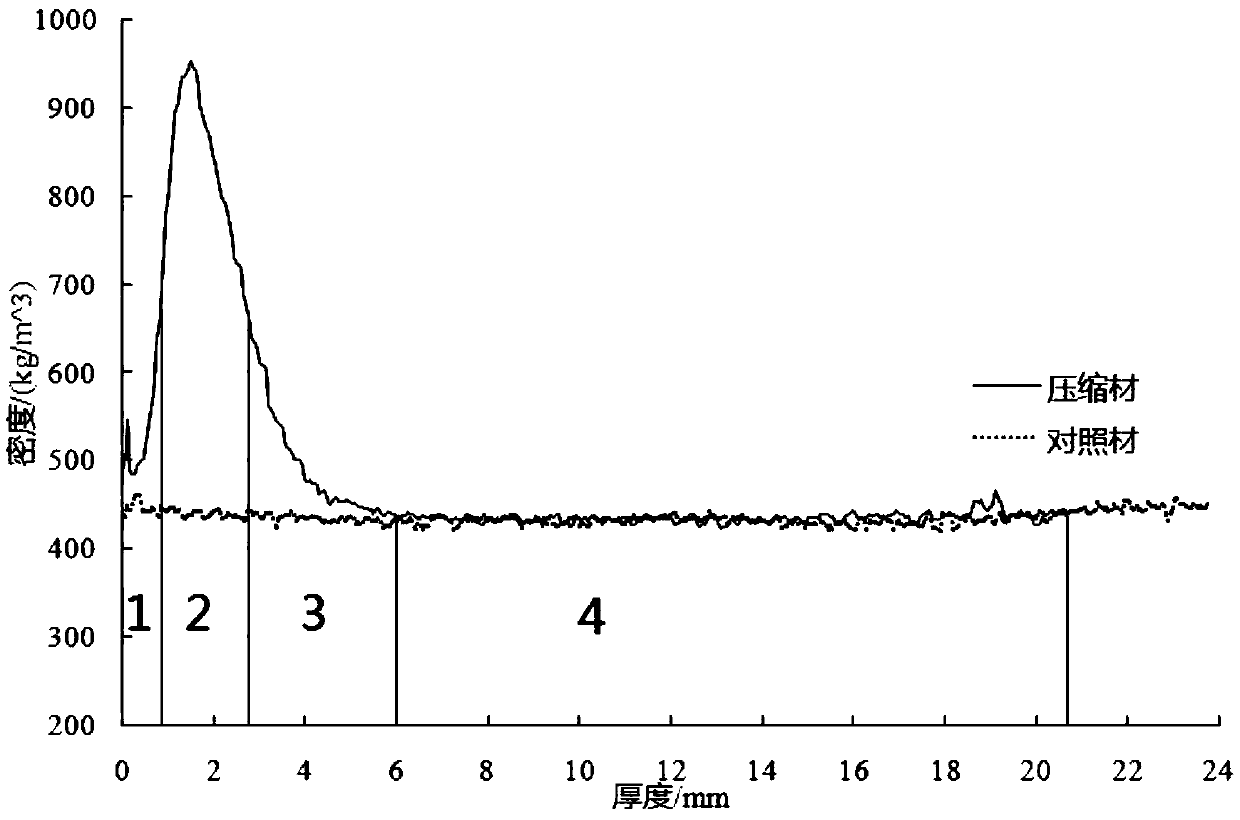

Embodiment 2

[0045] (1) Double-sided planing of Poplar tomentosa wood with a dry moisture content of 20% is prepared into a board with a size of 680×110×24 mm;

[0046] (2) Turn on the hot press, raise the temperature of the upper and lower platens to 220°C, lay three pieces of poplar wood planed on both sides neatly in a single row on the 12 mm heat insulation lining board, place the wood on both sides 20 mm thickness gauge, place the backing plate and wood together on the lower pressing plate that is preheated to the required temperature;

[0047] (3) close the press, make the hot plate on the press contact with the poplar wood upper surface, preheat 150 seconds;

[0048] (4) The pressure of the press is set to 12 MPa, and the wood is compressed to the required thickness at a feed rate of 0.22 mm / s, and then maintained for 180 seconds;

[0049] (5) The temperature of the lower platen is raised to 225°C, and the heating rate is 30°C / min;

[0050] (6) Reduce the pressure to 3 MPa, and ma...

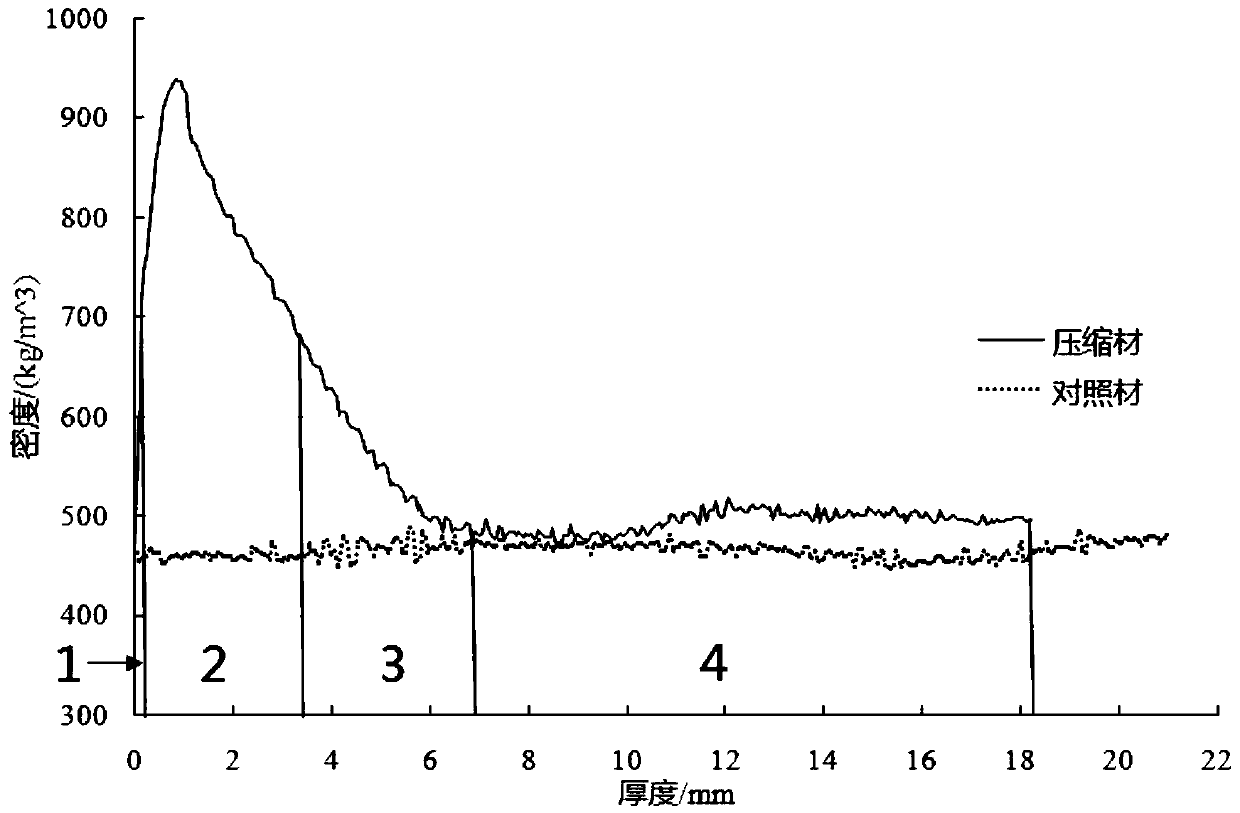

Embodiment 3

[0054] (1) Double-sided planing of rubber wood with a room dry moisture content of 10% is prepared into a board with a size of 980×105×21 mm;

[0055] (2) Turn on the hot press, raise the temperature of the upper and lower platens to 180°C, lay three pieces of double-sided planed rubber wood in a single row on the 8mm heat-insulating lining board, and place 18mm on both sides of the wood. Millimeter thickness gauge, place the backing plate and wood together on the lower pressing plate that is preheated to the required temperature;

[0056] (3) Close the press, make the hot plate on the press contact with the upper surface of the rubber wood, and preheat for 70 seconds;

[0057] (4) The pressure of the press is set to 10 MPa, and the wood is compressed to the required thickness at a feed rate of 0.18 mm / s, and then maintained for 200 seconds;

[0058] (5) Raise the temperature of the lower platen to 183°C, and the heating rate is 20°C / min;

[0059] (6) Reduce the pressure to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com