Single side surface layer compressed wood and preparation method thereof

A technology of compressing wood and surface layer, applied in the direction of wood compression, etc., can solve the problems of difficult control of the density distribution of compressed wood, affecting the wood yield, and unsatisfactory use effect, so as to improve dimensional stability, save compression loss, and save energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

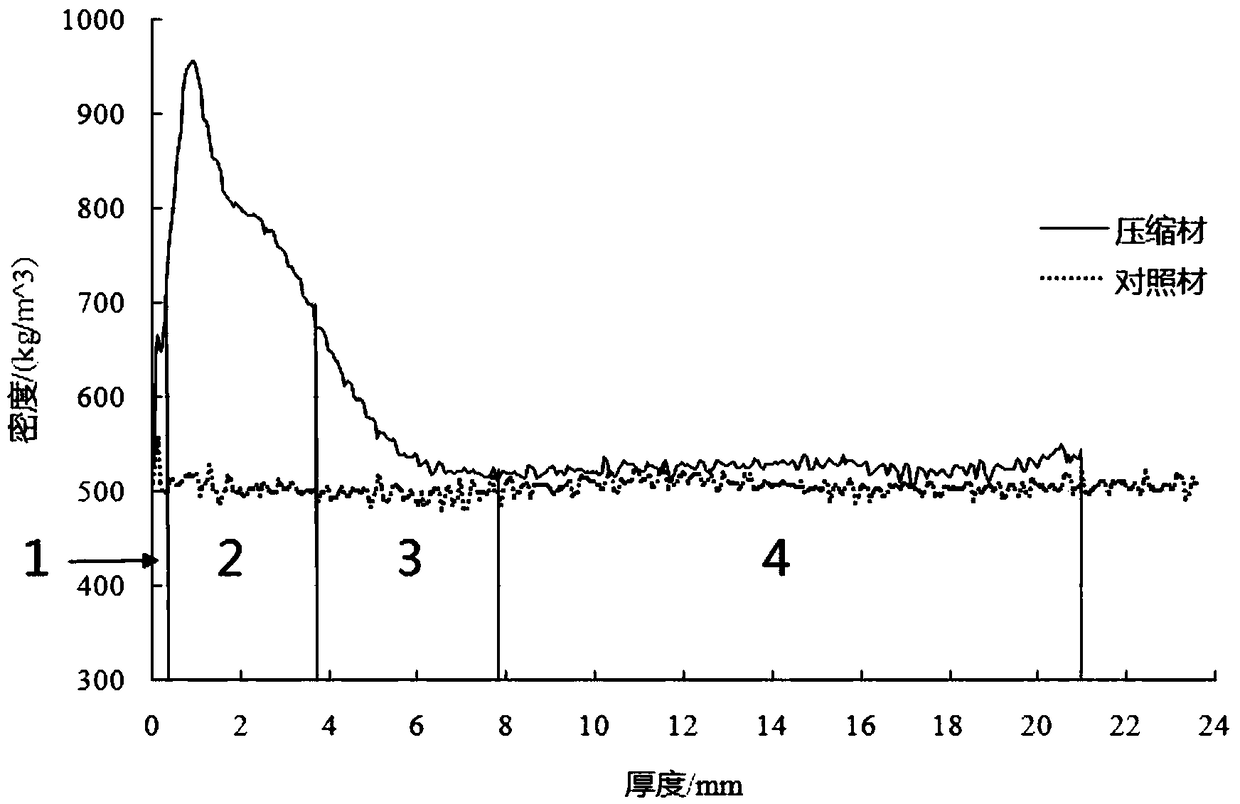

Embodiment 1

[0034] (1) Double-sided planing of Poplar tomentosa wood dried to a moisture content of 12% is prepared into a board with a size of 780 × 130 × 23.5 mm;

[0035] (2) Turn on the hot press, raise the temperature of the upper platen to 150°C, and the temperature of the lower platen to 50°C, and lay the three pieces of aspen wood planed on both sides neatly on the backing plate in a single row. Place 21mm thickness gauges on both sides, and place the backing plate and wood together on the lower pressure plate preheated to the target temperature;

[0036] (3) Close the press, make the hot plate on the press contact the upper surface of the wood of Populus tomentosa, and preheat for 20 seconds;

[0037] (4) Set the press pressure to 6 MPa, compress the wood to the target thickness at a feed rate of 0.10 mm / sec, and then hold the pressure for 120 seconds;

[0038] (5) the lower platen is heated to the same temperature as the upper platen, and the heating rate is 20°C / min;

[0039]...

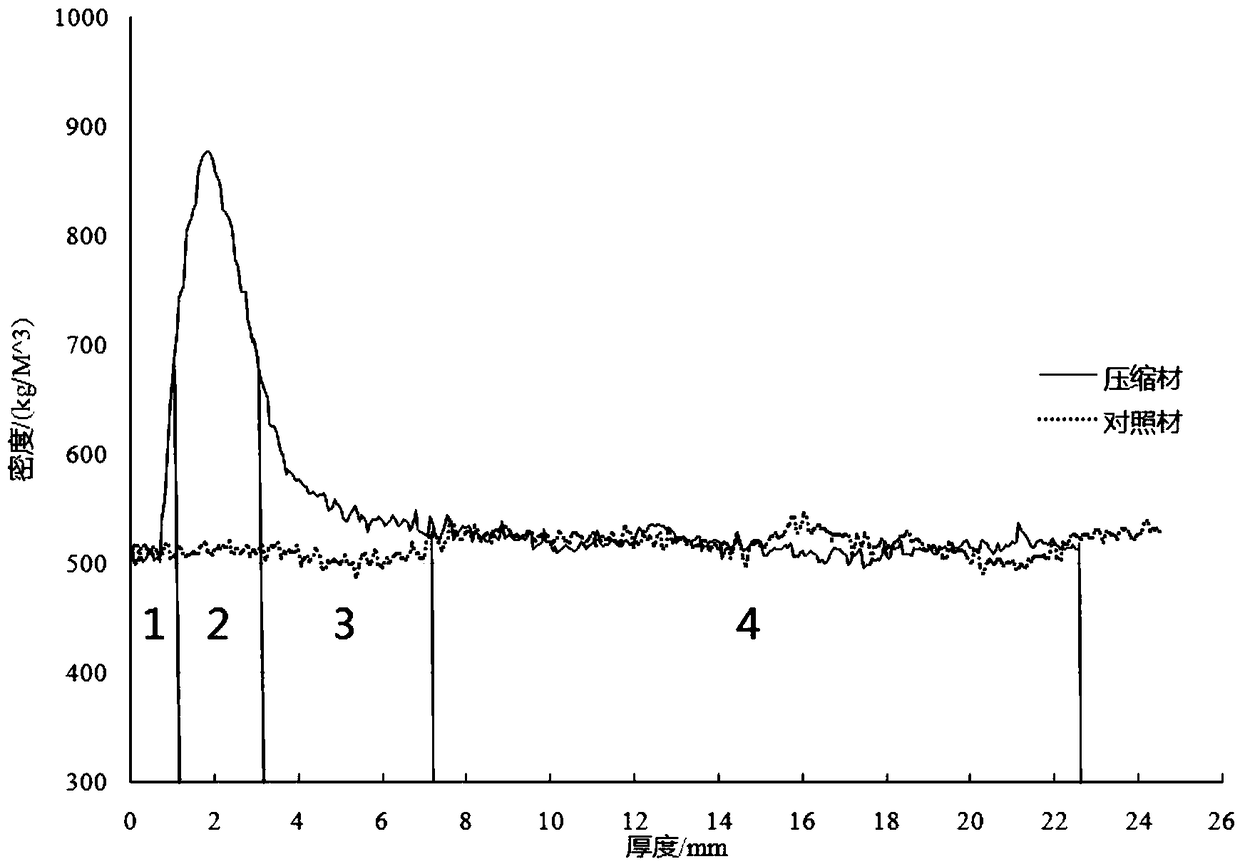

Embodiment 2

[0043] (1) Double-sided planing of Poplar tomentosa wood with an air-drying moisture content of 20% is prepared into a board with a size of 650 × 110 × 24.5 mm;

[0044] (2) Turn on the hot press, raise the temperature of the upper platen to 200°C, and the temperature of the lower platen to 80°C, and lay the three pieces of aspen wood with double-sided planing on the backing plate neatly in a single row. Place 22mm thickness gauges on both sides, and place the backing plate and wood together on the lower pressure plate preheated to the target temperature;

[0045] (3) Close the press, make the hot plate on the press contact the upper surface of the wood of Populus tomentosa, and preheat for 45 seconds;

[0046] (4) Set the press pressure to 10 MPa, compress the wood to the target thickness at a feed rate of 0.25 mm / sec, and then hold the pressure for 240 seconds;

[0047] (5) the lower platen is heated to the same temperature as the upper platen, and the heating rate is 50°C / ...

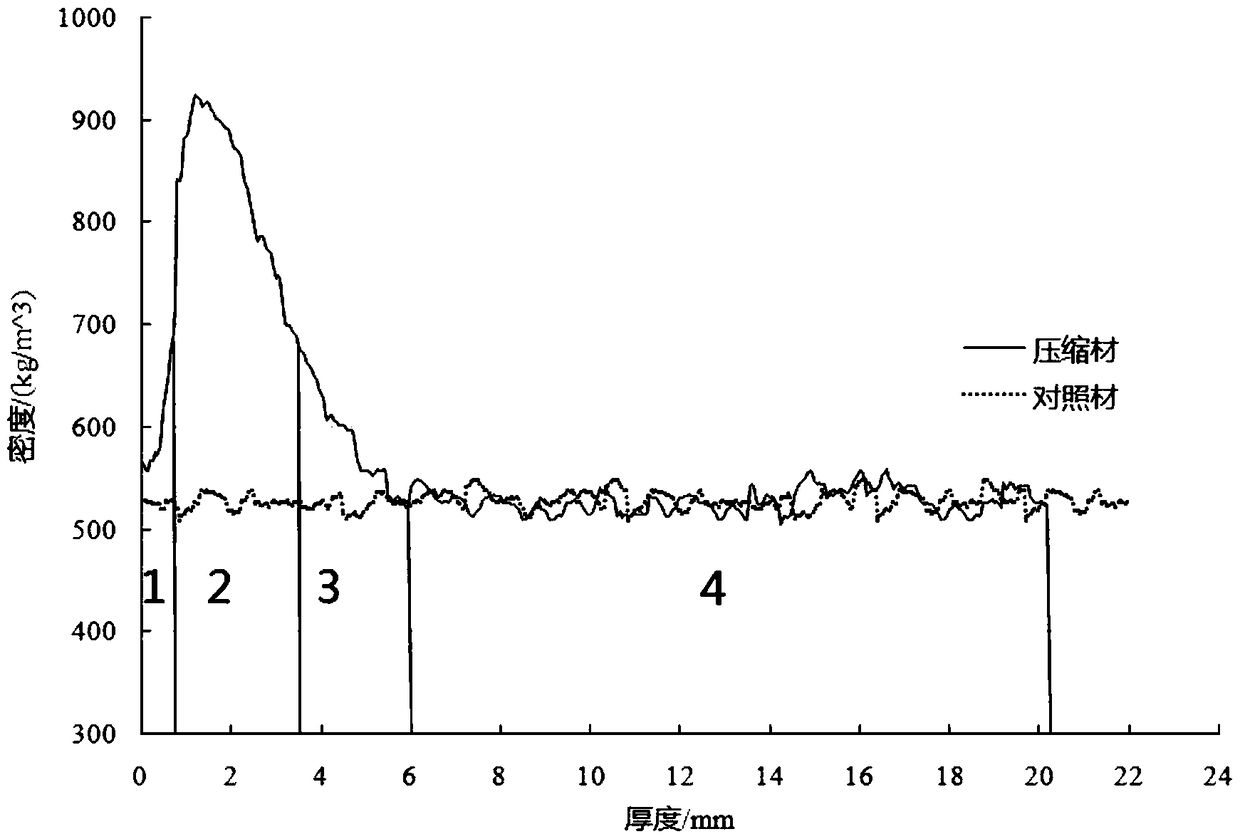

Embodiment 3

[0052] (1) Double-sided planing of the rubber wood dried to a moisture content of 10% is prepared into a board with a size of 1050×105×22 mm;

[0053] (2) Turn on the hot press, raise the temperature of the upper platen to 180°C and the temperature of the lower platen to 85°C, and lay the three pieces of rubber wood planed on both sides neatly on the backing plate in a single row. Place a thickness gauge of 20 mm on the side, and place the backing plate and wood together on the lower pressure plate preheated to the target temperature;

[0054] (3) Close the press, make the hot plate on the press contact the upper surface of the rubber wood, and preheat for 75 seconds;

[0055] (4) Set the press pressure to 12 MPa, compress the wood to the target thickness at a feed rate of 0.12 mm / sec, and then hold the pressure for 180 seconds;

[0056] (5) the lower platen is heated to the same temperature as the upper platen, and the heating rate is 35°C / min;

[0057] (6) Reduce the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com