Geopolymer based fibreboard

A technology of fiberboard and geopolymer, which is applied in the field of geopolymer-based fiberboard, can solve the problems of high production energy consumption, high production cost, and high maintenance condition requirements, and achieve the effects of increasing production cost, simple construction, and reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

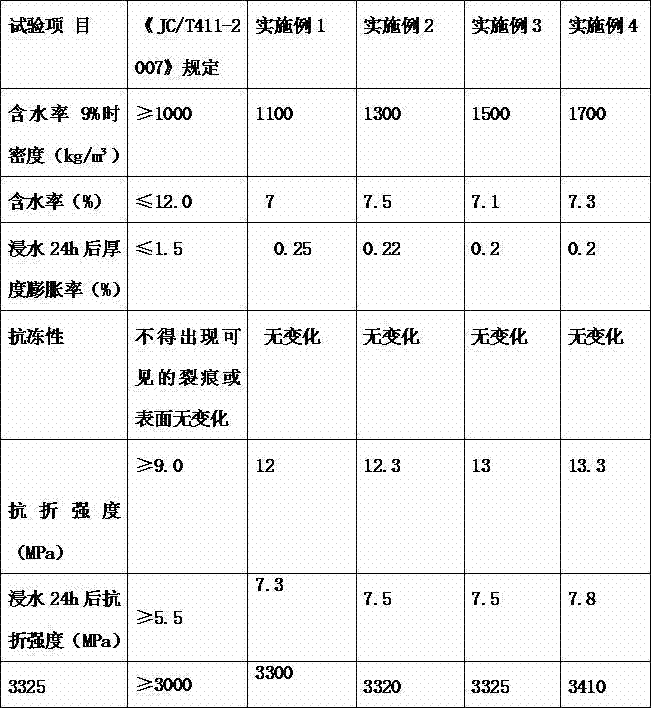

Examples

Embodiment 1

[0018] Raw material ratio:

[0019] Component Formula (kg) Liquid water glass (modulus 1.8, solid content 36%) 28 Blast furnace slag (100 mesh) 30.2 Steel slag (200 mesh) 16.8 wood fiber 20 Fiberglass (20-30mm long) 3 Polypropylene fiber (5-8mm long) 0

Embodiment 2

[0021] Raw material ratio:

[0022] Component Formula (kg) Liquid water glass (modulus 1.5, solid content 37%) 30 Slag (325 mesh) 29.5 Steel slag (100 mesh) 20.7 wood fiber 17.75 Fiberglass (20-30mm long) 1.8 Polypropylene fiber (5-8mm long) 0.25 total 100

Embodiment 3

[0024] Raw material ratio:

[0025] Component Formula (kg) Liquid water glass (modulus 2.5, solid content 37%) 30.33 Slag (600 mesh) 30.9 Steel slag (600 mesh) 19.66 wood fiber 16.85 Fiberglass (20-30mm long) 2 Polypropylene fiber (5-8mm long) 0.26 total 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com