Fat injection applied to injection cosmetology and preparation method

An injection and fat technology, applied in the field of injection beauty, can solve the problems of low survival rate of transplanted fat, poor cosmetic effect of injection, liquefaction of transplanted fat, etc., to improve the concentration and survival rate, ensure the curative effect, and promote the effect of autologous fat growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

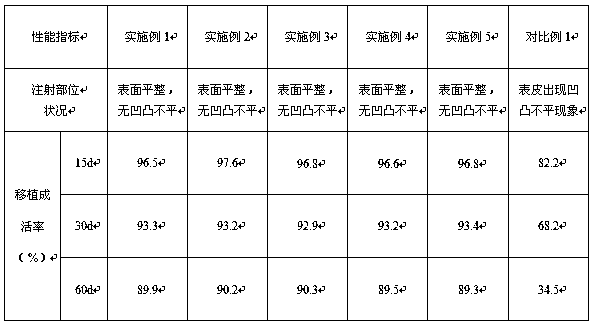

Examples

Embodiment 1

[0035] The preparation process is:

[0036] (1) Extraction of autologous inner thigh fat;

[0037] (2) The fat is frozen and ground by liquid nitrogen; the temperature of the frozen grinding is -50°C, and the particle size of the ground fat is 50 μm.

[0038] (3) Rinse the ground fat with brine under nitrogen atmosphere; the mass concentration of brine is 30%.

[0039] (4) Add water and an emulsifier to the fat, followed by ultrasonic emulsification to obtain an emulsion; the emulsifier is polyethylene glycol. The ultrasonic processing frequency is 300 kHz, and the processing time is 40 min. In the emulsion, 30 parts by weight of fat, 69 parts by weight of water, and 1 part by weight of emulsifier.

[0040](5) Add nano-scale silica airgel into the emulsion, disperse evenly, and then add a demulsifier to destroy the emulsion system, and a large number of fat stem cells remain in the pores of nano-scale silica airgel; the demulsifier is poly Oxyethylene polyoxypropylene stea...

Embodiment 2

[0047] The preparation process is:

[0048] (1) Extraction of autologous inner thigh fat;

[0049] (2) Freezing and grinding the fat with liquid nitrogen; the temperature of the freezing and grinding is -20°C, and the particle size of the ground fat is 100 μm.

[0050] (3) Rinse the ground fat with brine under nitrogen atmosphere; the mass concentration of brine is 30%.

[0051] (4) Add water and an emulsifier to the fat, followed by ultrasonic emulsification to obtain an emulsion; the emulsifier is sodium dodecylsulfonate. The ultrasonic processing frequency is 200 kHz, and the processing time is 50 min. In the emulsion, 35 parts by weight of fat, 63 parts by weight of water, and 2 parts by weight of emulsifier.

[0052] (5) Add nano-scale silica airgel into the emulsion, disperse evenly, and then add a demulsifier to destroy the emulsion system, and a large number of fat stem cells remain in the pores of nano-scale silica airgel; the demulsifier is poly Oxyethylene polyo...

Embodiment 3

[0059] The preparation process is:

[0060] (1) Extraction of autologous inner thigh fat;

[0061] (2) The fat is frozen and ground by liquid nitrogen; the temperature of the frozen grinding is -40°C, and the particle size of the ground fat is 150 μm.

[0062] (3) Rinse the ground fat with brine under nitrogen atmosphere; the mass concentration of brine is 30%.

[0063] (4) Add water and an emulsifier to the fat, followed by ultrasonic emulsification to obtain an emulsion; the emulsifier is fatty acid polyoxyethylene ether. The ultrasonic processing frequency is 300 kHz, and the processing time is 40 min. In the emulsion, 30 parts by weight of fat, 68 parts by weight of water, and 2 parts by weight of emulsifier.

[0064] (5) Add nano-scale silica airgel into the emulsion, disperse evenly, and then add a demulsifier to destroy the emulsion system, and a large number of fat stem cells remain in the pores of nano-scale silica airgel; the demulsifier is fat Alcohol Sulfate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com