Aerial-bomb-penetration-resisting steel pipe ceramic ball basalt fiber concrete protection plate

A technology of basalt fiber and concrete, which is applied in the direction of earthquake resistance, building materials, building components, etc., can solve the problems of single structure, insufficient anti-aircraft bomb penetration performance, and poor comprehensive anti-aircraft bomb penetration performance, so as to achieve simple structural design , Improve the protective performance, improve the effect of protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

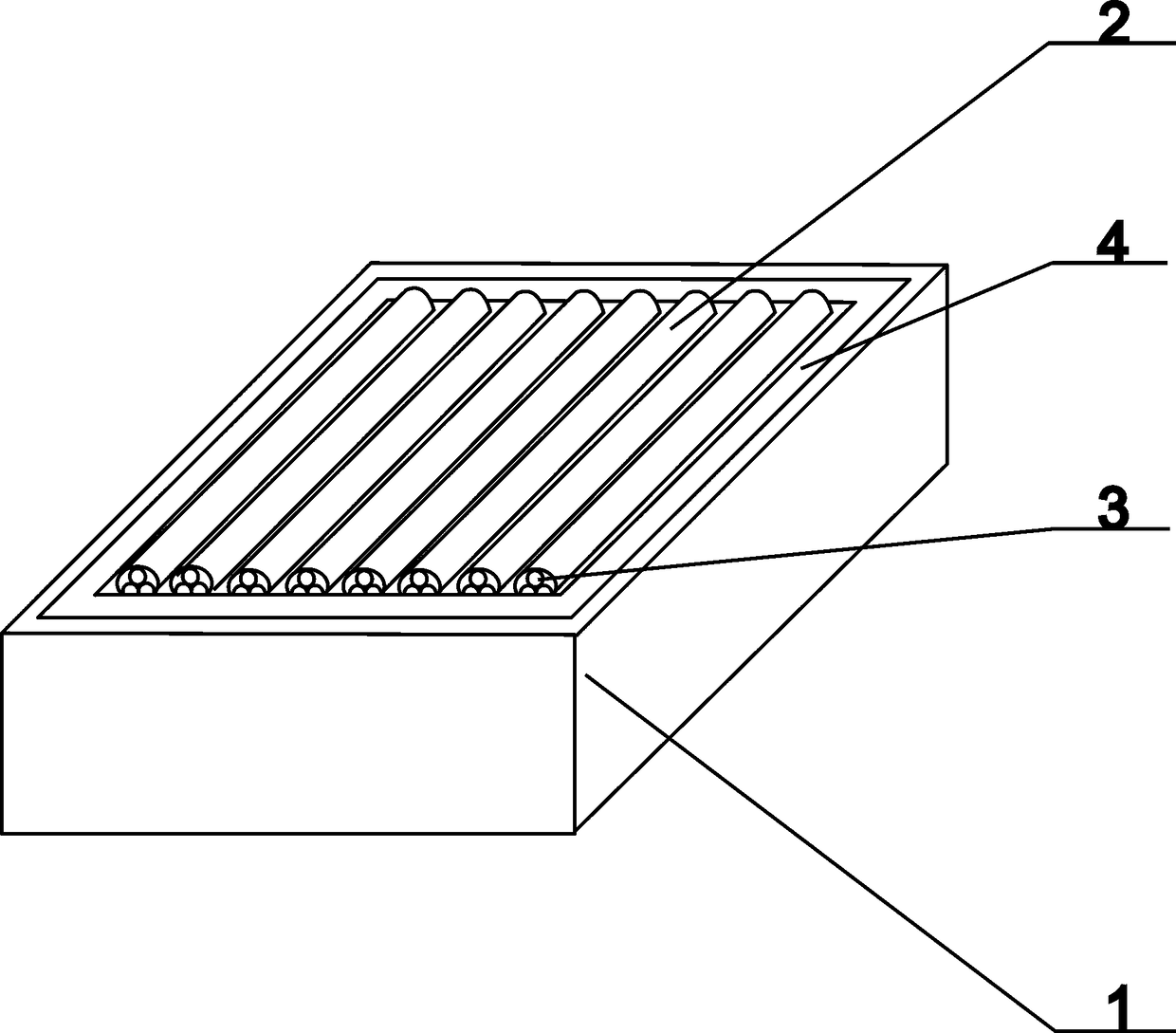

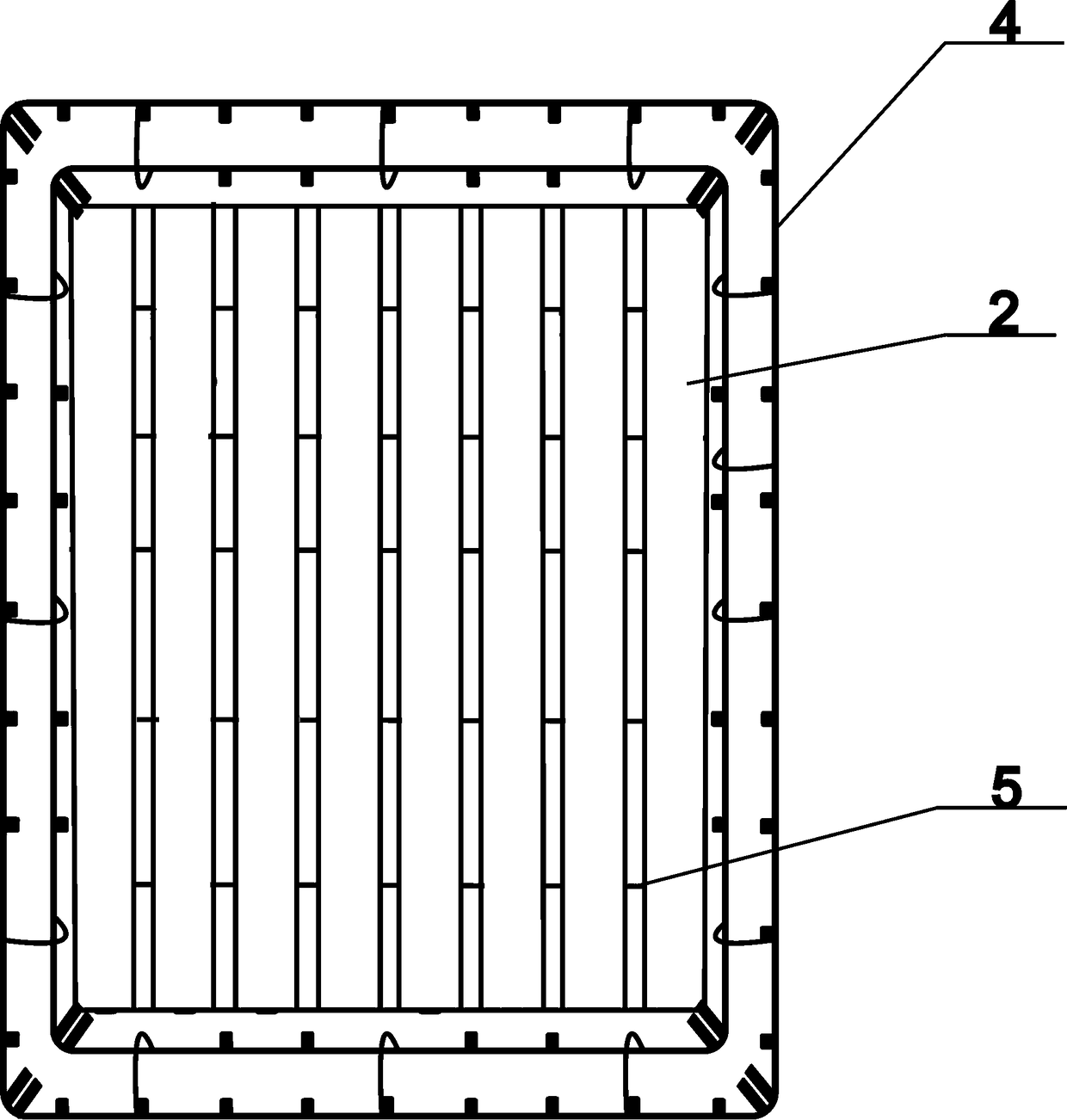

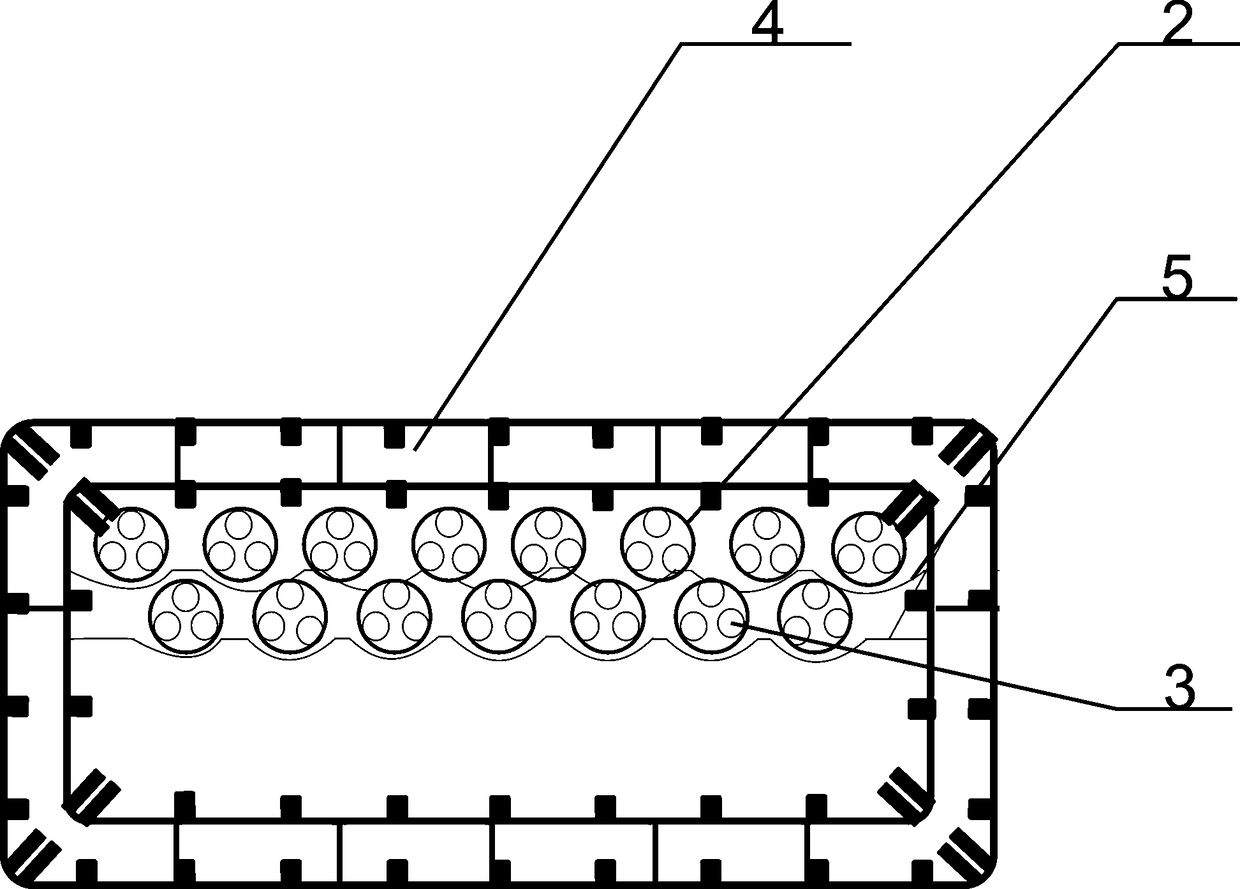

[0037] As shown in the figure, a steel pipe ceramic ball basalt fiber concrete protective plate for anti-aircraft bomb penetration includes a basalt fiber concrete matrix 1, a steel pipe 2, and ceramic balls 3; the basalt fiber concrete matrix 1 is formed by mixing basalt fiber and concrete to form a hollow In the square cavity of the basalt fiber concrete matrix 1, the thickness of pouring and filling basalt fiber concrete is 500mm; the steel pipe 2 is fixedly set in the square cavity of the basalt fiber concrete matrix 1, the upper part of the basalt fiber concrete, the steel pipe 2 is in the shape of Spacing and uniform horizontal setting, the steel pipe 2 is fixedly arranged with two layers, the diameter of the steel pipe 2 is 150mm, the upper layer of steel pipe 2 and the lower layer of steel pipe 2 are set up and do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com