Mobile hot wedge welder, hot wedge and welding method

A technology of automatic device and hot wedge, applied in movable hot wedge welding automatic device, hot wedge and welding field, can solve the problem of impossible welding speed, and achieve the effect of simplified operation, less noise and slow welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

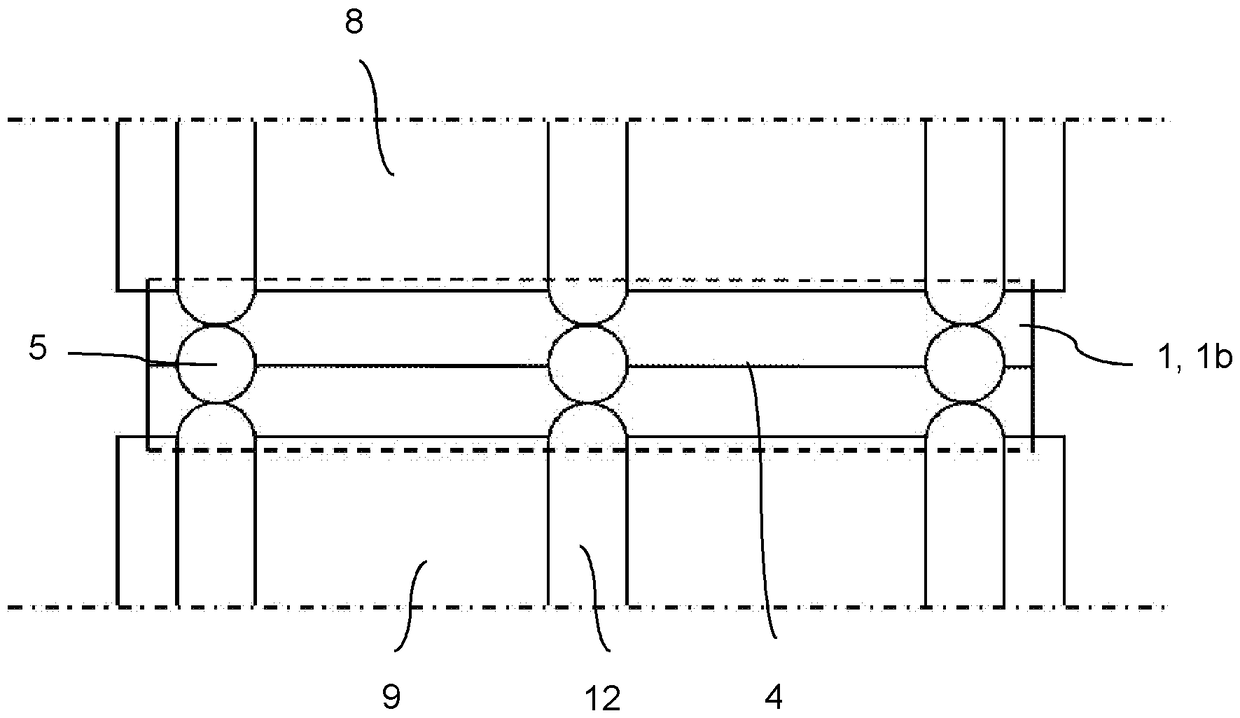

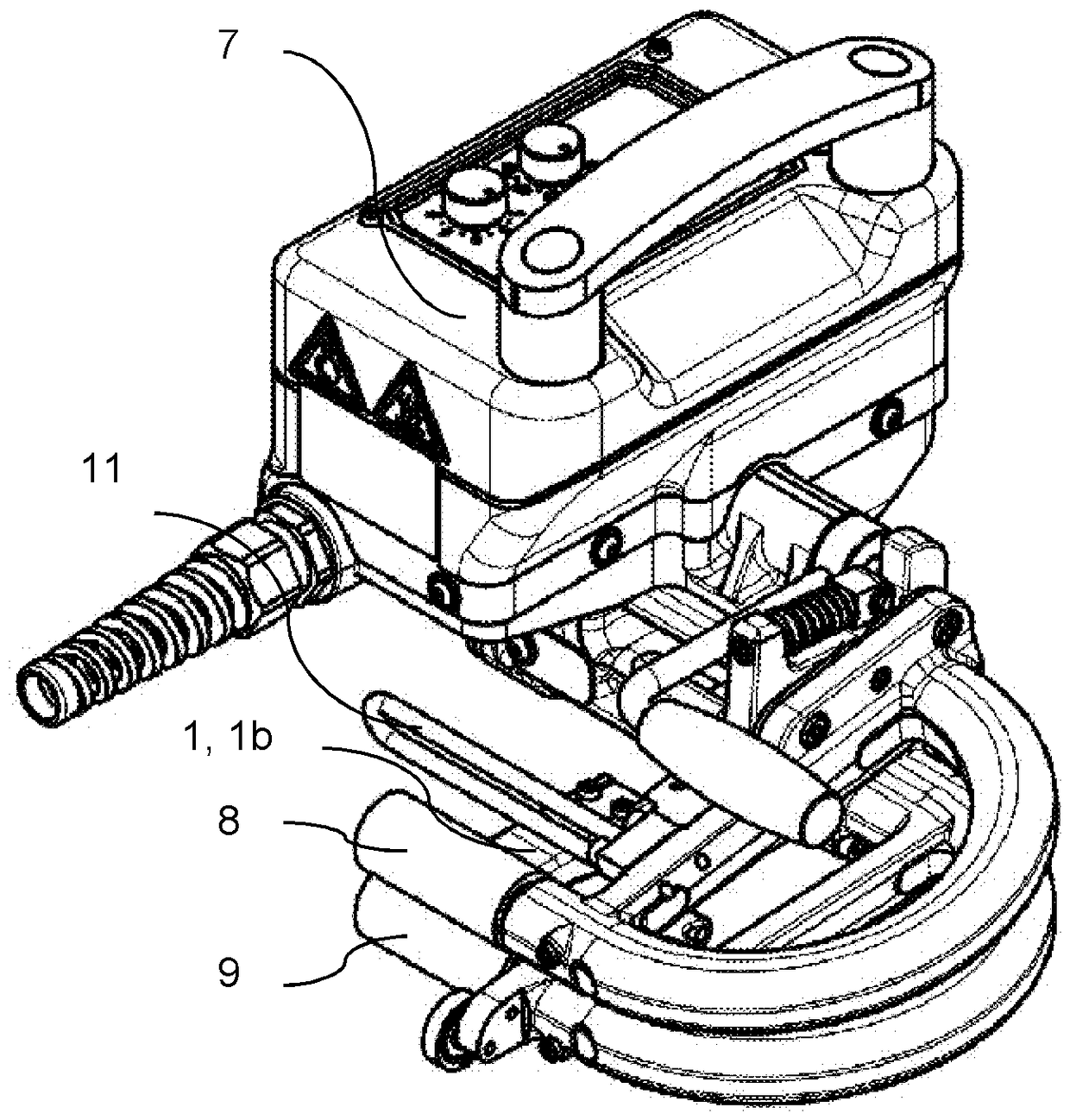

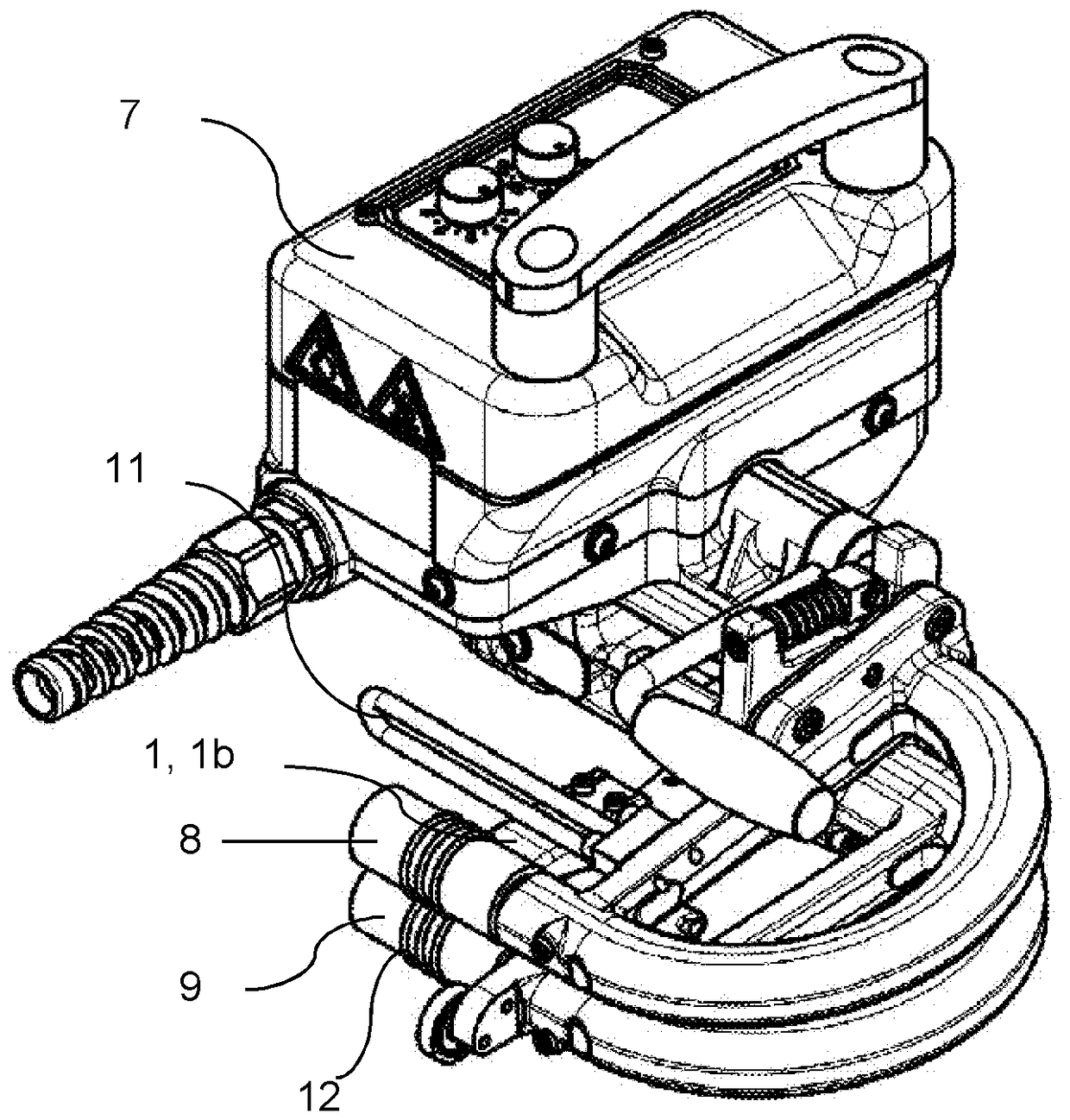

[0027] figure 1 A thermal wedge 1 is shown in different embodiments. All thermal wedges 1 have an upper guide surface 2 as well as a lower guide surface 3 not visible in the figures, said upper and lower guide surfaces, especially in the front region near the thermal wedge tip 4, usually in contact with the The plastic film comes into thermal contact. The connection surface 13 is used for electrical and mechanical contacting of the thermal wedge 1 with a welding device or a welding robot. The thermal wedges 1 a and 1 b have two or three contact elements 5 on the thermal wedge tip 4 , which are designed as thermal wedge lugs connected to the thermal wedge tip 4 with balls at the end. During soldering, the contact element 5 is thermally contacted both by the lower plastic film and by the upper plastic film. The spherical contact element projection 5 therefore has a radius both in the transverse direction and in the longitudinal direction of the thermal wedge and thus brings a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com