Surface adhesion cooling micro-machining tool for minimum quantity lubricant system

A technology for cutting tools and micro-lubrication, which is applied in the direction of manufacturing tools, metal processing equipment, drilling accessories, etc., can solve the problems of excessively long and small diameter of the chip removal channel, reduce the surface accuracy of the workpiece, and increase the wear speed of the tool, so as to avoid chips Noise and secondary chips, improved tool life, and improved lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the implementation scope of the present invention is not limited thereto.

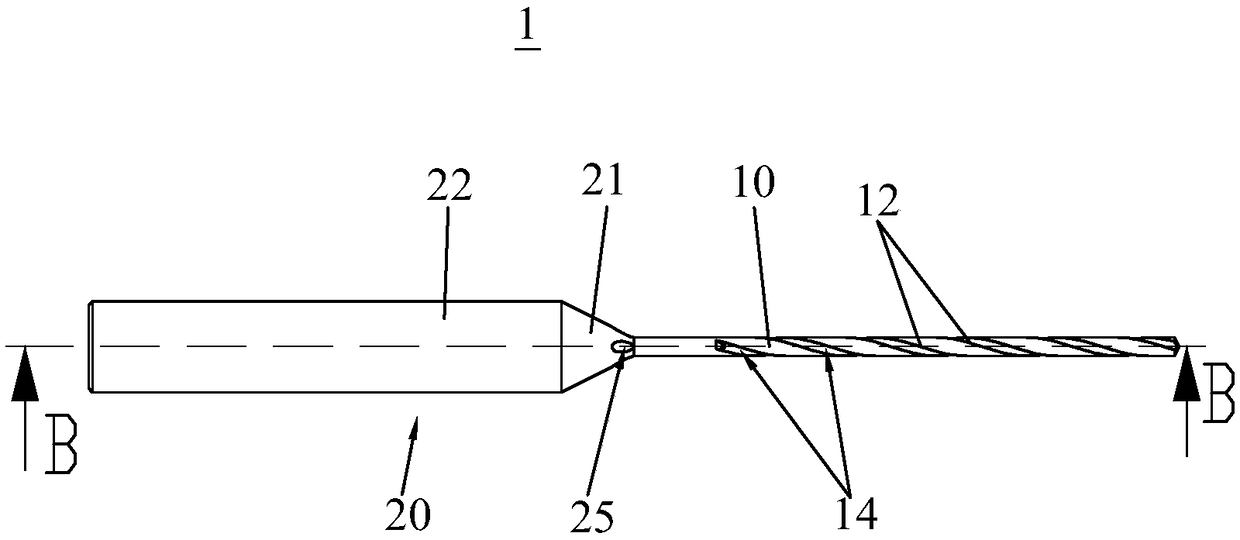

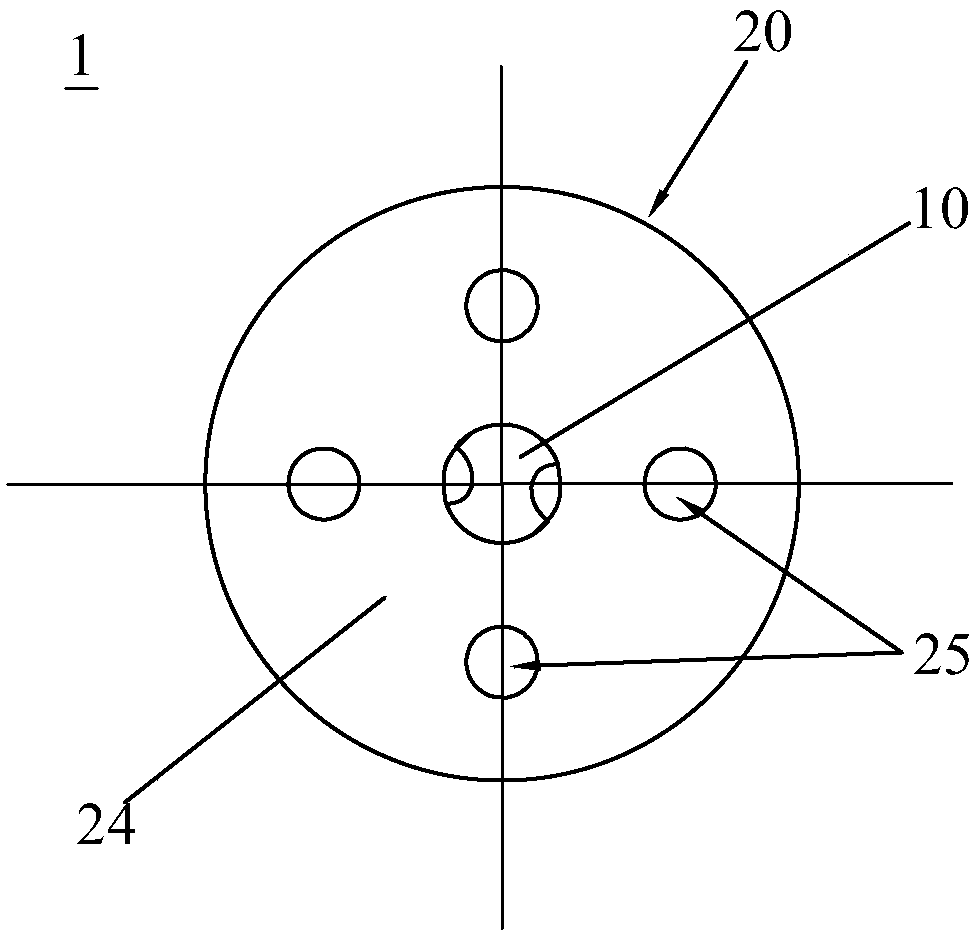

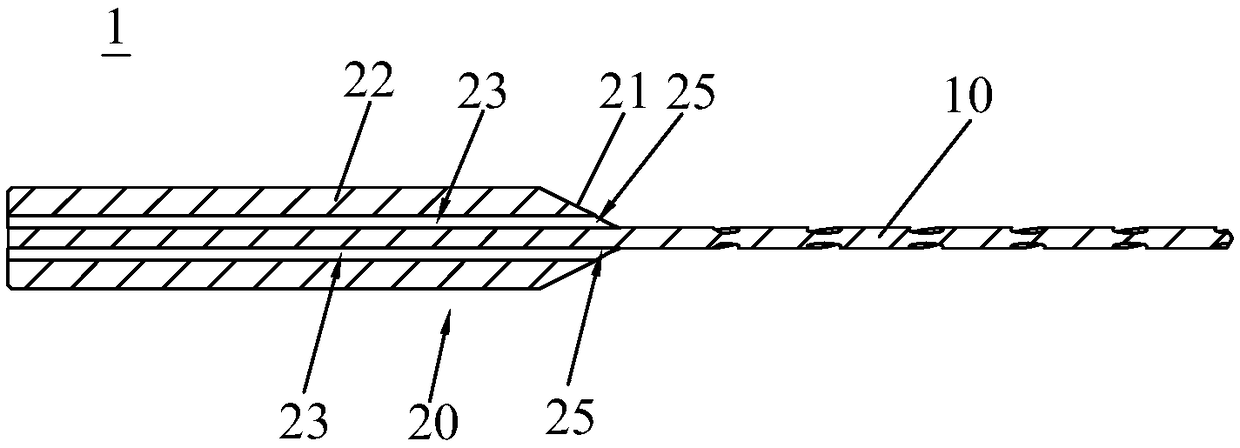

[0025] like Figure 1~3 As shown, the present invention is applicable to the micro-machining tool 1 of the veneer cooling, lubricating, chip flushing and chip removal that is applicable to the micro-lubrication system. Improve the service life of the veneer cooling micro machining tool 1, the surface quality and precision of the workpiece, and the working efficiency of the machine tool. Specifically, as shown in the figure, the veneer cooling micromachining tool 1 includes a tool blade portion 10 disposed at one end in the axial direction and a tool holding handle 20 disposed at the other end, and divides the veneer cooling micromachining tool 1 The multiple parts are only for the convenience of description, in fact, the face-cooled micro-machining tool 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com