Moringa leaf and ginseng health product and preparation method thereof

A health care product, Moringa leaf technology, applied in the directions of food ingredients, food forming, food ingredient functions, etc., can solve the problems of generating toxic and harmful wastes, complicated operation processes, and various solvents, and achieves no toxic side effects. , the preparation process is simple, the effect of strong efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of Moringa leaf ginseng health care product and preparation method thereof, comprising the following steps:

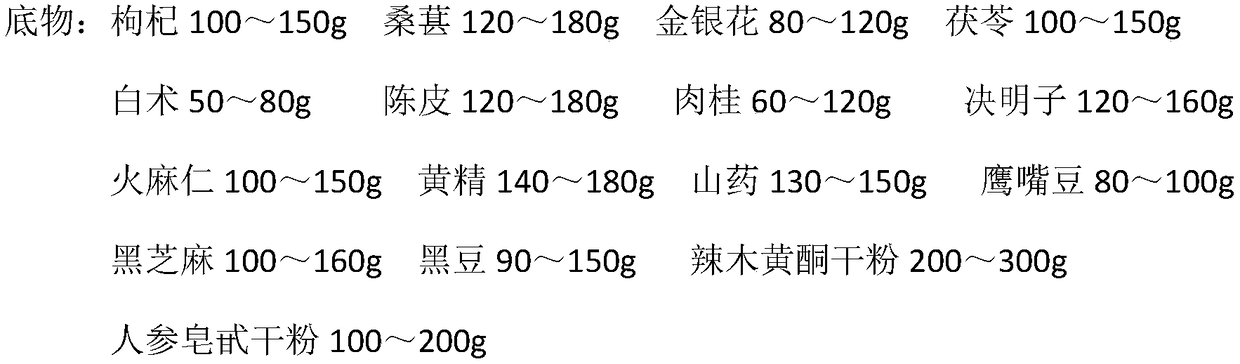

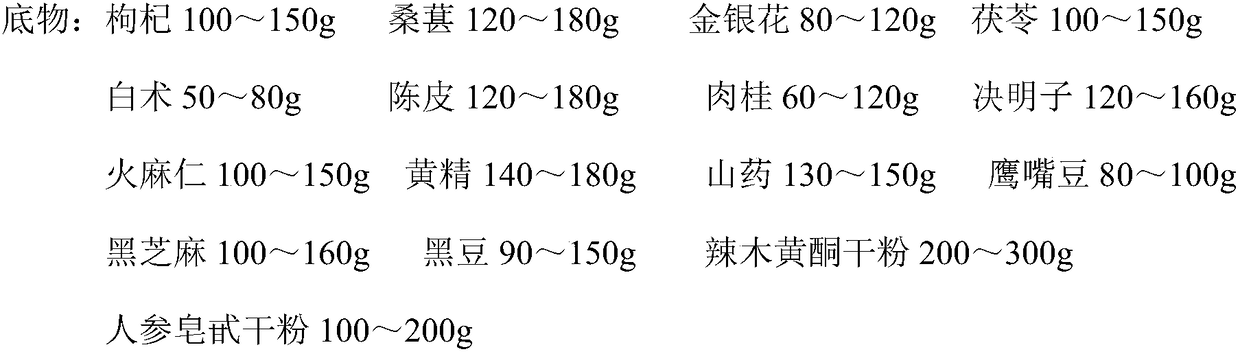

[0024] Step 1. Take the raw materials and crush them into debris. The raw materials and weight ratio are as follows: 100-150g wolfberry, 120-180g mulberry, 80-120g honeysuckle, 100-150g poria cocos, 50-80g Atractylodes macrocephala, 120-180g Chenpi, 60-120g cinnamon, 120-160g cassia seeds, 100-150g hemp seed, 140-180g sealwort, 130-150g yam, 80-100g chickpeas, 100-160g black sesame and 90-150g black beans;

[0025] Step 2: Add 200-300g of Moringa flavonoids dry powder and 100-200g of ginsenoside dry powder to the detritus-like raw materials and stir to mix the raw materials evenly. Sterilize at a temperature of 70-80°C and a pressure of 0.2-0.8 MPa for 10 ~30min, then add 1.69*10 4 ~5.06*10 4 CFU of bifidobacterium, using edible organic acid to adjust the pH value to 5.5-6.5, the temperature is 35-40°C, stirring and fermenting at the speed of 600-1400r / ...

Embodiment 1

[0030] Take raw materials, the content of each substrate is as follows: 100g wolfberry, 120g mulberry, 80g honeysuckle, 100g poria cocos, 50g white bamboo, 120g tangerine peel, 60g cinnamon, 120g cassia seed, 100g hemp seed, 140g sealwort, 130g yam, 80g chickpea, 100g Black sesame and 90g black soybeans, crushed into pieces, then add 200g Moringa flavonoids dry powder and 100g ginsenoside dry powder and stir to mix the dry powders evenly, sterilize at a temperature of 70°C and a pressure of 0.2MPa for 10min, then add The quantity is 1.69*10 7 The CFU bifidobacterium auxiliary material is adjusted to a pH of 5.5 with citric acid, and the temperature is 35° C., and the stirring and fermentation are carried out at a speed of 600 r / min for 10 hours. After the fermentation is completed, the product is transferred to a lyophilizer and freeze-dried at a temperature of -10°C. Finally, pulverize and grind to 200 mesh, then add 0.1% of food additive magnesium stearate accounting for th...

Embodiment 2

[0032] Take the raw materials, the content of each substrate is as follows: 125g wolfberry, 150g mulberry, 100g honeysuckle, 125g poria cocos, 65g white bamboo, 150g tangerine peel, 90g cinnamon, 140g cassia seed, 125g hemp seed, 160g sealwort, 140g yam, 90g chickpea, 130g Black sesame and 120g black soybeans, crushed to debris, then add 250g dry powder of Moringa flavonoids and 150g dry powder of ginsenosides and stir to mix the dry powders of each medicinal material evenly, sterilize at a temperature of 75°C and a pressure of 0.6MPa for 15min, then The added quantity is 3.165*10 7 The CFU bifidobacterium auxiliary material is adjusted to pH 6 with malic acid, the temperature is 37.5°C, and the stirring and fermentation is carried out at a speed of 1000r / min for 15h. After the fermentation is completed, the product is transferred to a lyophilizer and freeze-dried at a temperature of -15°C. Finally, pulverize and grind to 250 mesh, then add 0.4% of food additive magnesium ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com