Dual-model fault diagnosis method based on dynamic weighing

A dynamic weighting, fault diagnosis technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve the problems of long convergence time, failure diagnosis methods cannot incorporate empirical knowledge, large differences, etc., to achieve good theoretical and Application value, improving the accuracy of fault diagnosis, and the effect of good performance evaluation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

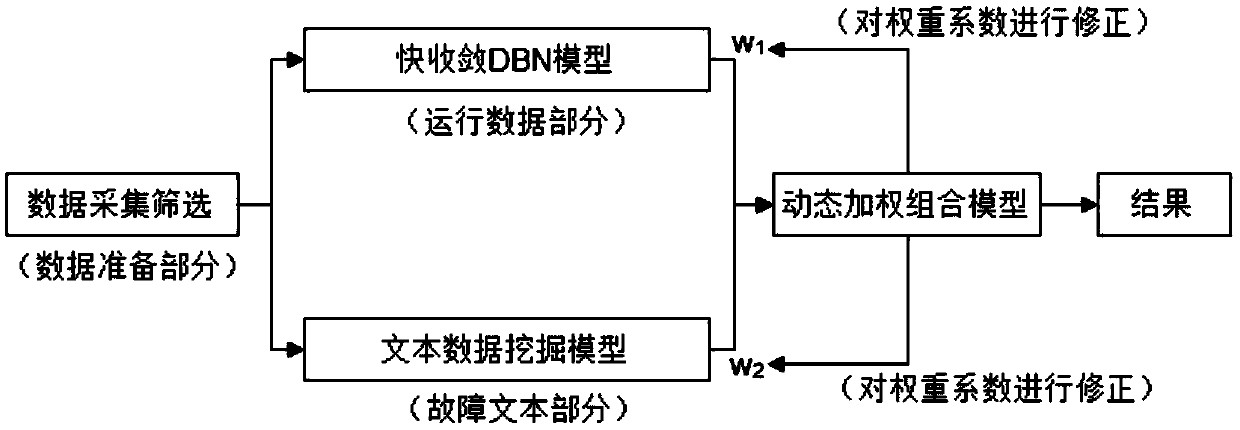

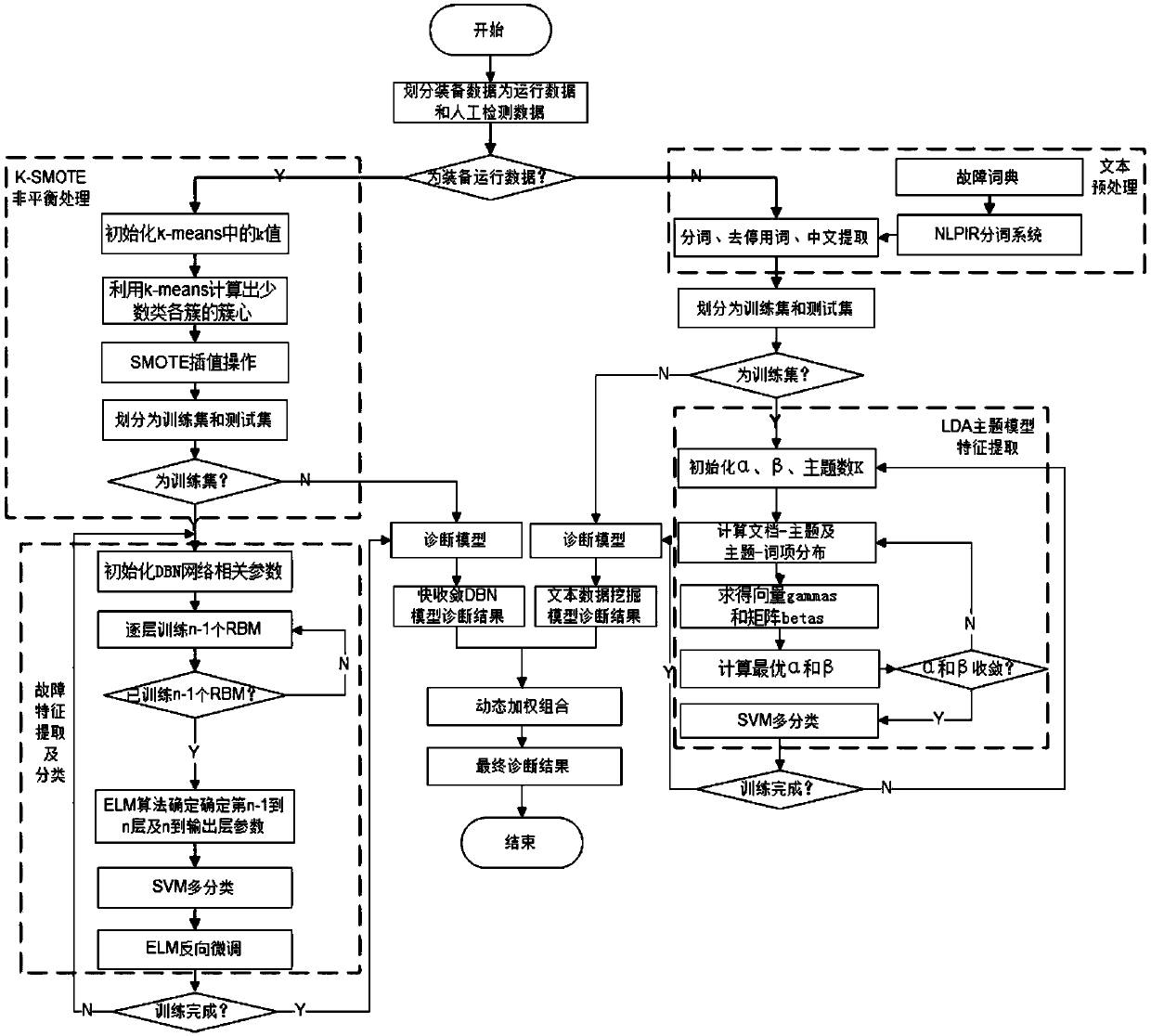

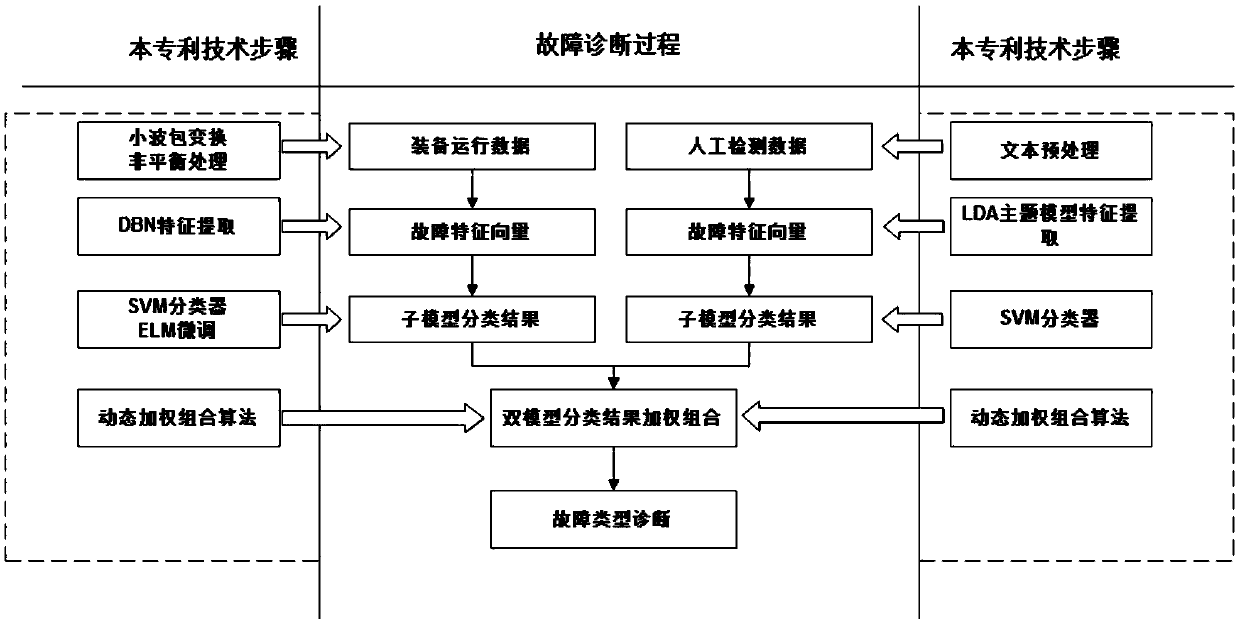

Method used

Image

Examples

Embodiment

[0093] Experimental verification of the dual-model fault diagnosis method based on dynamic weighting:

[0094] 1. Data description

[0095] Such as Figure 3-6 As shown, the experiment takes the bearing vibration data and fault record text provided by a certain company as an example, and selects rolling bearing samples that are worn and have local faults during use. The main fault types are: wear, fatigue spalling, corrosion, fracture, There are seven types of gluing, indentation and cage damage. The fault samples of different damage degrees under the fault state of the inner ring of the rolling bearing are recorded as FT1, FT2, FT3, FT4, FT5, FT6, FT7. Select the normal state (FT0), wear state (FT1), fatigue peeling state (FT2), corrosion state (FT3), fracture state (FT4), glued state (FT5), indentation state (FT6) collected by the vibration sensor at the motor drive end. ) and cage damage state (FT7), the sampling frequency is 12000HZ, the rotating shaft rotates one circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com