Method for inversion calibration of microscopic constitutive parameters of metal material on the basis of nanoindentation and finite element simulation

A nano-indentation, metal material technology, applied in the application of stable tension/pressure to test the strength of materials, analyze materials, measuring devices, etc., can solve the problem of difficult to achieve accurate inversion and calibration of microscopic constitutive parameters, and unable to obtain the only optimal It can solve problems such as huge set of solutions and non-inferior solutions, and achieve the effects of high practical value and reference significance, low cost, and high-speed and accurate calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

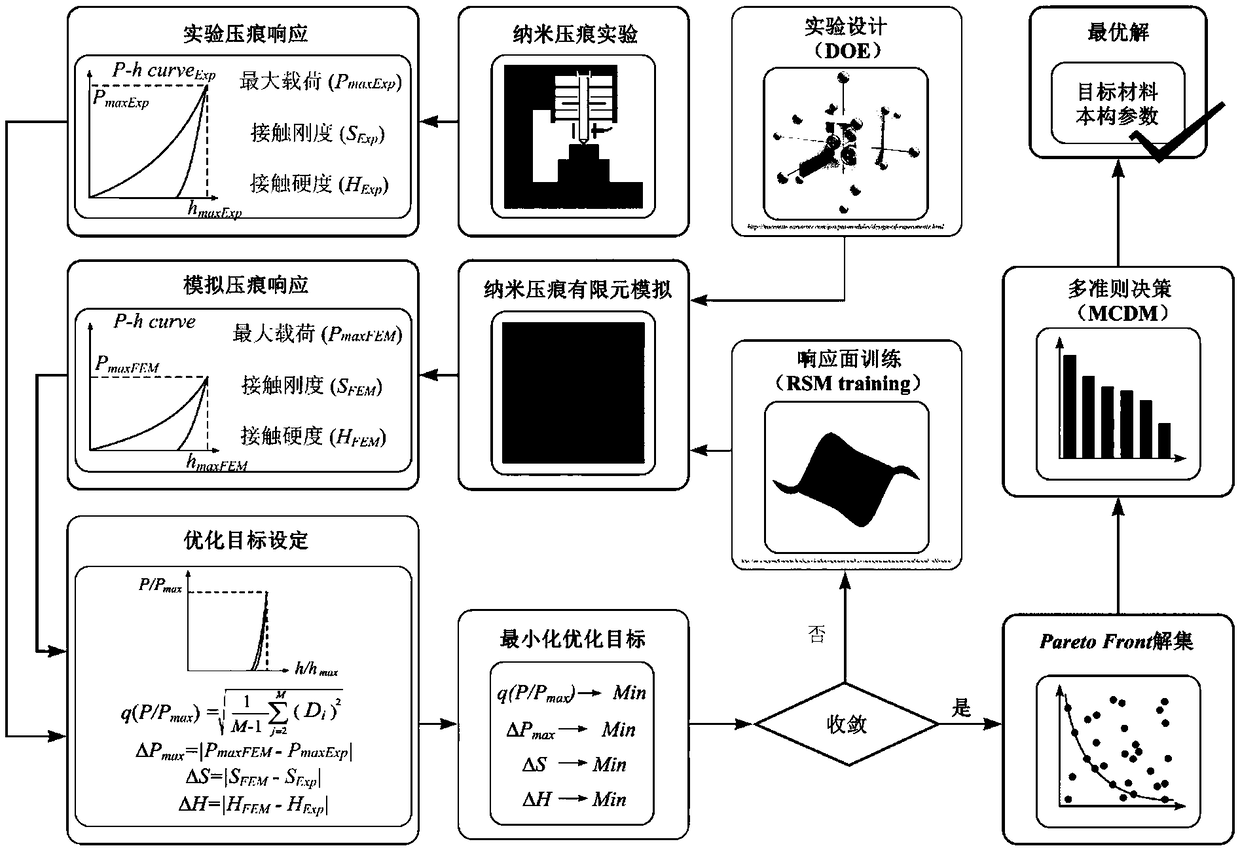

Method used

Image

Examples

Embodiment 1

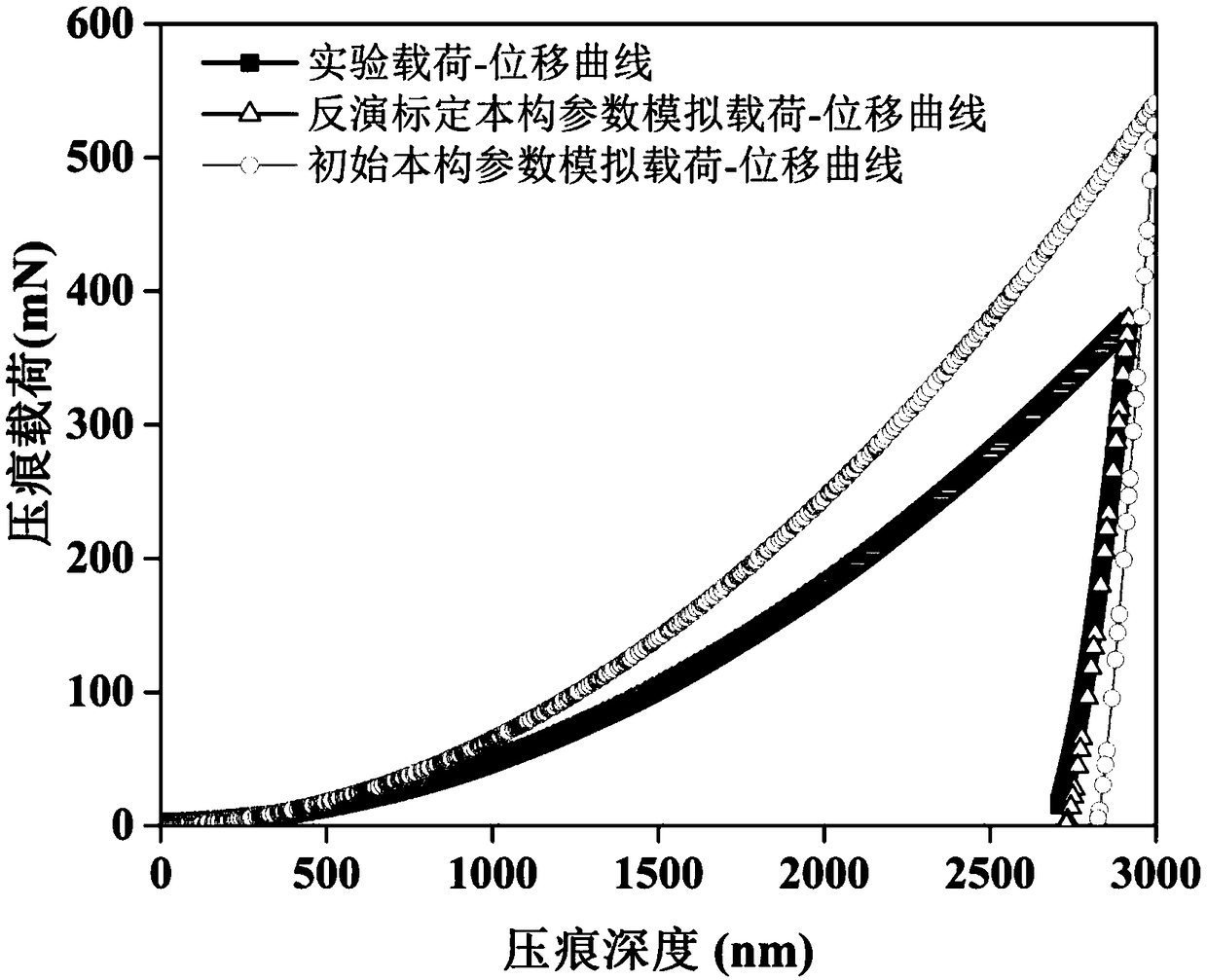

[0069] T40 alloy is a kind of α-phase 2 grade industrial pure titanium, which has good plasticity, toughness, high temperature resistance and corrosion resistance. It is widely used in the industrial field, especially in the field of nuclear energy. It is an important nuclear pressure vessel and pipeline material. . The above method is used to invert and calibrate the microscopic constitutive parameters of T40 alloy, and the parameters obtained by inversion calibration are substituted into the finite element model for simulation. The comparison between the obtained simulated indentation response and the corresponding experimental indentation response is as follows image 3 and shown in Table 1. in, image 3 is the comparison between the simulated load-displacement curve (P-h curve) and the experimental curve, Table 1 is the simulated maximum load (P maxFEM ), contact stiffness (S FEM ) and contact hardness (H FEM ) compared with the corresponding experimental values.

[0...

Embodiment 2

[0074] Ti-18 alloy is a near-β-phase high-strength titanium alloy newly developed by TIMET Company of the United States in 2011. It has a yield strength of 1400MPa, a tensile strength of 1600MPa and an elongation of 8%. A new generation of high-strength titanium alloy for high-strength steel for landing gear has great application value and broad application prospects in the field of aviation, especially civil aviation. The above method is used to invert and calibrate the microscopic constitutive parameters of Ti-18 alloy, and the parameters obtained by inversion calibration are substituted into the finite element model for simulation. The comparison between the obtained simulated indentation response and the corresponding experimental indentation response is as follows Figure 4 and shown in Table 2. in, Figure 4 is the simulated load-displacement curve (P-h curve) FEM Compared with the experimental curve, Table 2 shows the simulated maximum load (P maxFEM ), contact stiff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com