Submarine cable construction method for hydraulic power scouring, discharging, dredging and excavation

A submarine cable and construction method technology, which is applied in the direction of earth mover/excavator, mechanically driven excavator/dredger, construction, etc., can solve the problems of cable damage, unimaginable consequences, and high construction risk, so as to avoid damage , reduce construction risks, and achieve high dredging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A construction method for excavating submarine cables by hydraulic flushing and desilting, characterized in that the specific steps are as follows:

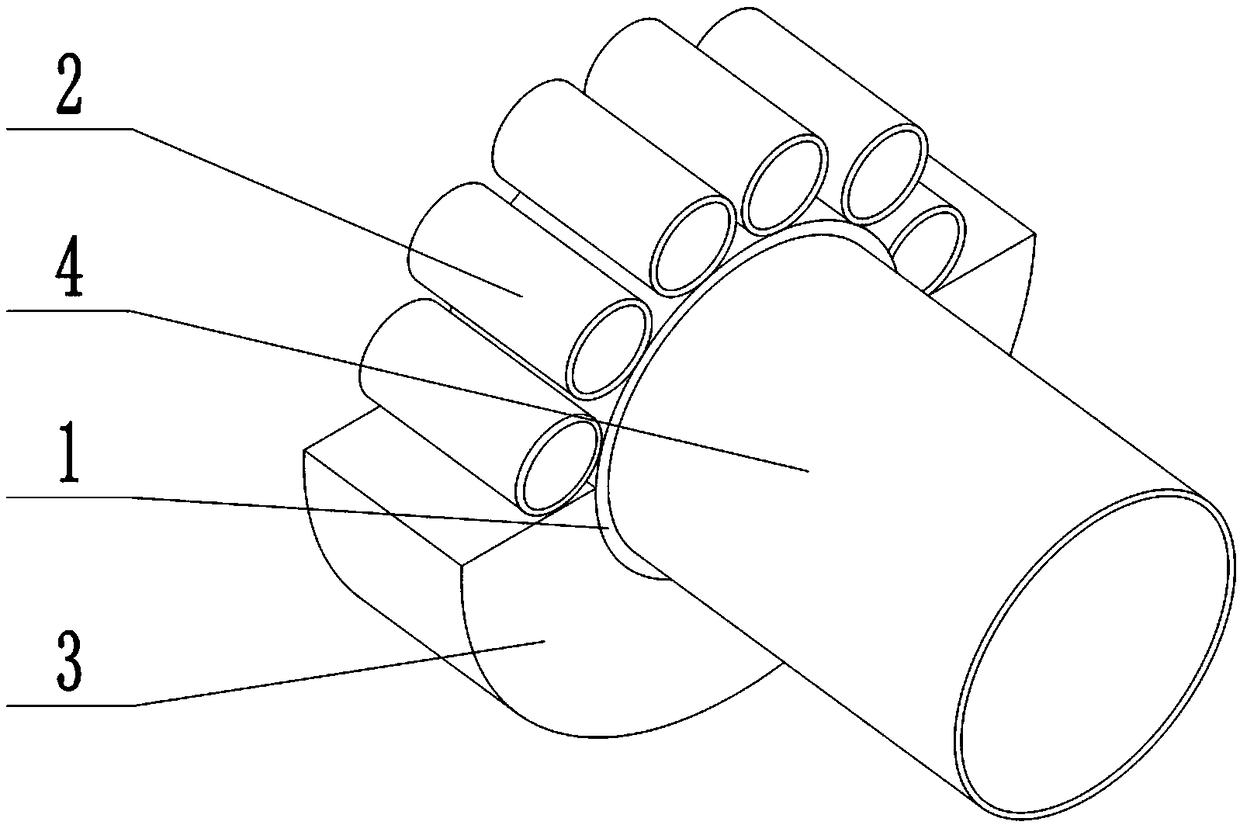

[0027] (a) Transform the cutter suction dredger into a flushing suction dredger, remove the reamer head of the original cutter suction dredger, add a flushing pipe along the upper circumference of the suction pipe head, and install several A high-pressure water gun 2, a rubber cushion 3 is provided at the bottom of the mud suction pipe 1, and a rubber hose 4 is connected with a flange at the end;

[0028] (b) After the dredger sucks the mud, it is transported to the mud barge through the fully enclosed mud discharge pipe to avoid polluting the sea area;

[0029] (c) After the suction dredger is positioned in the dredging construction area, loosen the steel cable of the bucket bridge winch in front of the ship, put the dredge nozzle into the water at a slow speed in a vertical fan shape, excavate according to the design, an...

Embodiment 2

[0035] A construction method for excavating submarine cables by hydraulic flushing and desilting, characterized in that the specific steps are as follows:

[0036] (a) Transform the cutter suction dredger into a flushing suction dredger, remove the reamer head of the original cutter suction dredger, add a flushing pipe along the upper circumference of the suction pipe head, and install several A high-pressure water gun 2, a rubber cushion 3 is provided at the bottom of the mud suction pipe 1, and a rubber hose 4 is connected with a flange at the end;

[0037] (b) After the dredger sucks the mud, it is transported to the mud barge through the fully enclosed mud discharge pipe to avoid polluting the sea area;

[0038] (c) After the suction dredger is positioned in the dredging construction area, loosen the steel cable of the bucket bridge winch in front of the ship, put the dredge nozzle into the water at a slow speed in a vertical fan shape, excavate according to the design, an...

Embodiment 3

[0044] A construction method for excavating submarine cables by hydraulic flushing and desilting, characterized in that the specific steps are as follows:

[0045] (a) Transform the cutter suction dredger into a flushing suction dredger, remove the reamer head of the original cutter suction dredger, add a flushing pipe along the upper circumference of the suction pipe head, and install several A high-pressure water gun 2, a rubber cushion 3 is provided at the bottom of the mud suction pipe 1, and a rubber hose 4 is connected with a flange at the end;

[0046] (b) After the dredger sucks the mud, it is transported to the mud barge through the fully enclosed mud discharge pipe to avoid polluting the sea area;

[0047] (c) After the suction dredger is positioned in the dredging construction area, loosen the steel cable of the bucket bridge winch in front of the ship, put the dredge nozzle into the water at a slow speed in a vertical fan shape, excavate according to the design, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com