FDY filament spinning-pulling machine

A combined machine and filament spinning technology, applied in filament/thread forming, stretch spinning, textiles and papermaking, etc., can solve the problems of many broken ends and affect product quality, and achieve the goal of improving quality and shortening production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

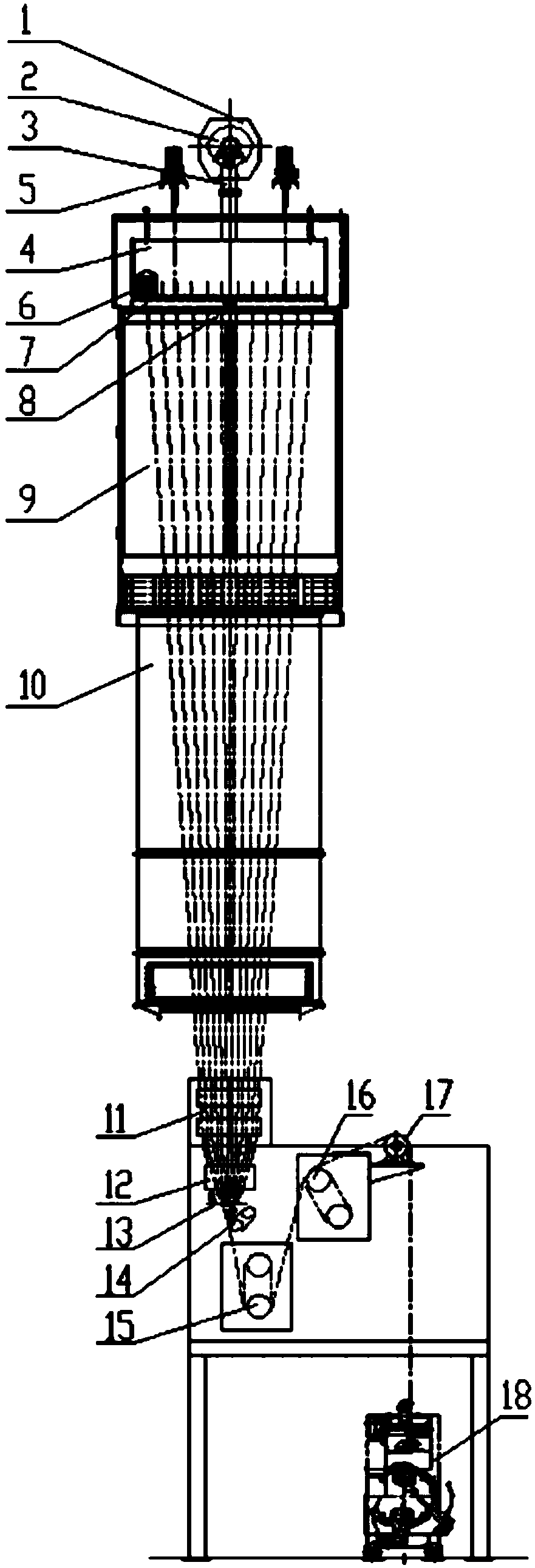

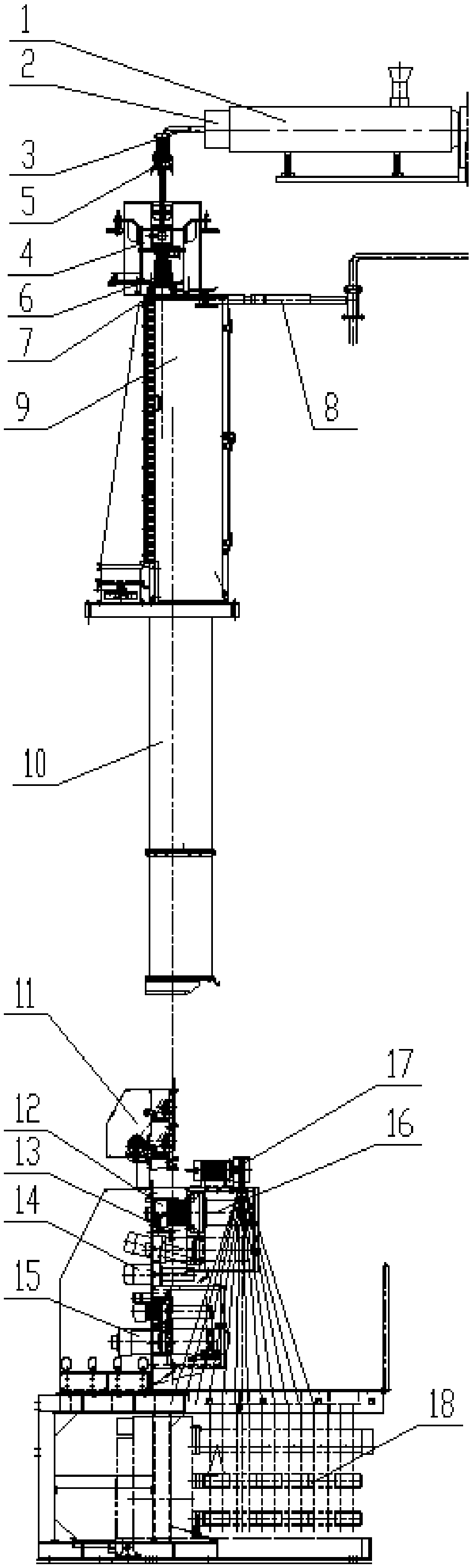

[0052] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

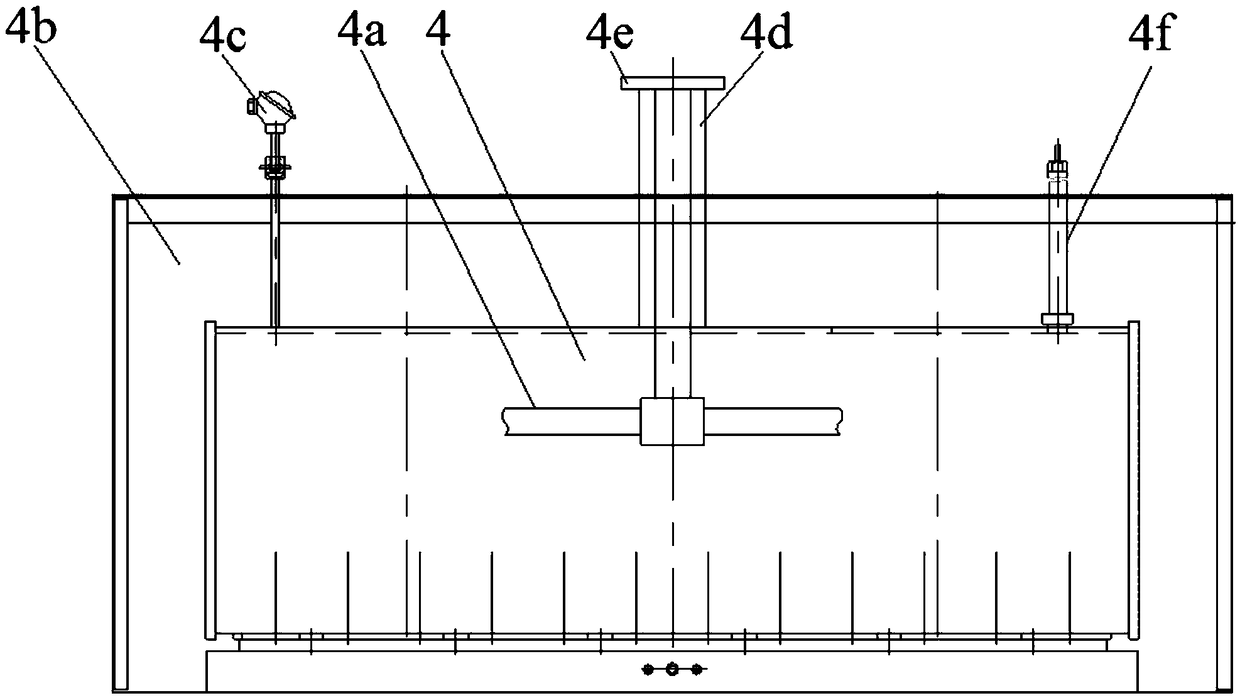

[0053] see figure 1 and figure 2 , a FDY filament spinning and pulling combination machine, including an extrusion device, a melt piping system 3, a metering pump 5, a spinning device, a cooling device, a tunnel part 10, an oiling device 11, and a guide wire arranged in sequence according to the production process Drafting device and winding device 18. Wherein, the cooling device comprises an annealer part 7, a monomer suction part 8 and a side air cooling part 9, and the annealer part 7 is communicated between the spinning device and the side air cooling part 9, and is located at the outlet of the spinning device. Wire end; slow cooler part 7 comprises delayed cooling air chamber 7f ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com