Single-runner dual-structure oxygen lance spraying head and blowing technology

An oxygen lance nozzle and double-structure technology, which is applied in the field of iron and steel metallurgy, can solve the problems of not discussing the influence of double nozzles, and cannot guarantee the impact strength and stirring strength, etc., and achieve the effects of significant slag removal, increased gaps, and reduced confluence possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

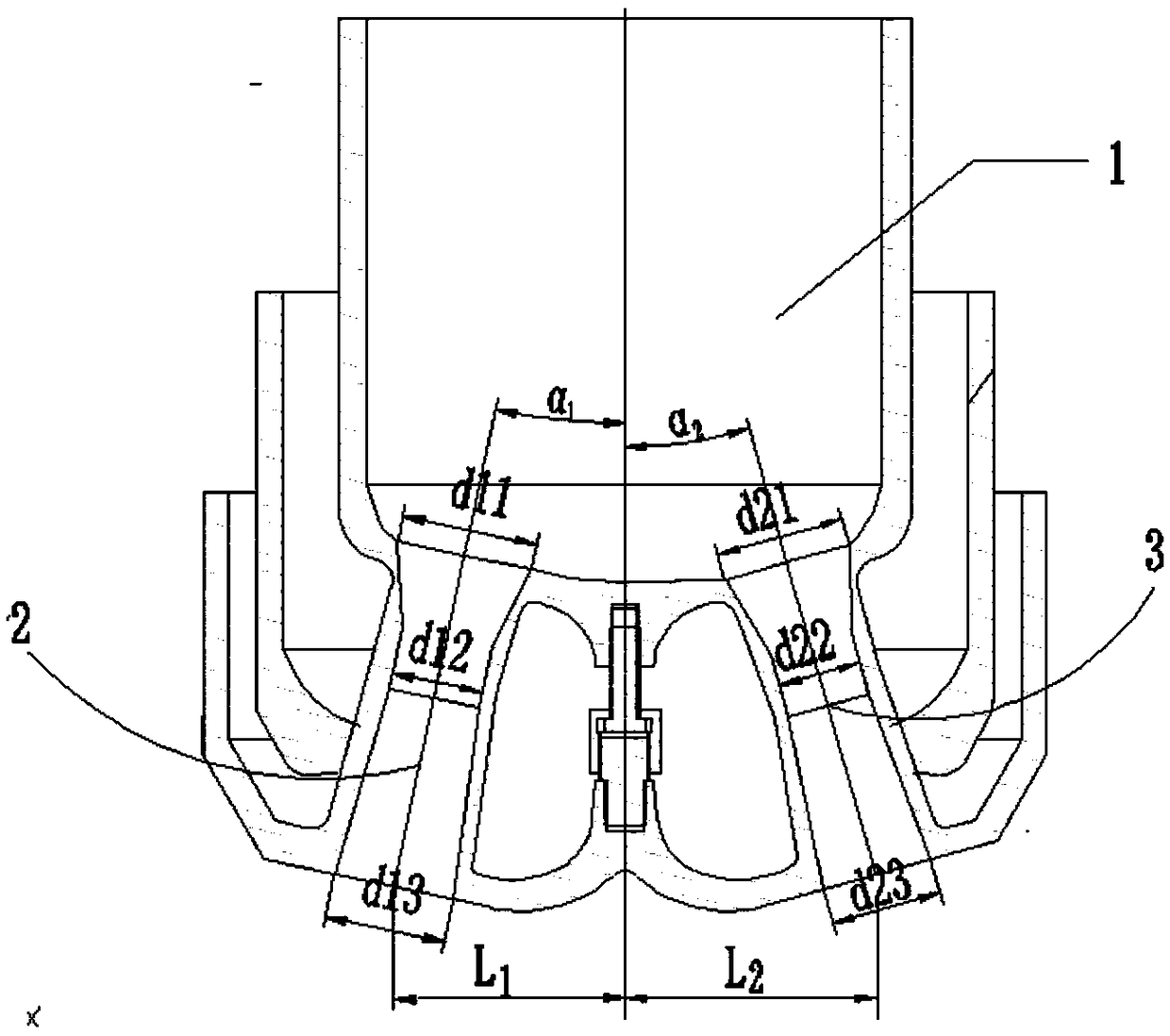

[0036] See Table 1 for the design parameters of the single-channel, double-angle, and double-flow oxygen lance nozzle for a 260-ton converter;

[0037] Table 1:

[0038]

[0039] See Table 2 for the comparative design parameters of the oxygen lance nozzle with single channel, dual angle, and dual flow for a 260-ton converter;

[0040] Table 2:

[0041]

[0042] 260-ton converter with single-channel double-angle double-flow nozzle blowing process parameters: the design flow rate of the main oxygen inlet is 48000m 3 / h, the total flow of oxygen is adjusted according to the capacity of the converter and the smelting process. The pressure at the main oxygen inlet is 1.1MPa. Both the main hole and the auxiliary holes are supersonic jets. The number of oxygen lance nozzles is 3 for the main hole and 3 for the auxiliary holes. The Mach number Ma of the jet outlet is 2.0.

[0043] Embodiment experimental results are shown in Table 3;

[0044] table 3:

[0045] par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com