Fireproof coating with high-temperature resistance and preparation method of fireproof coating

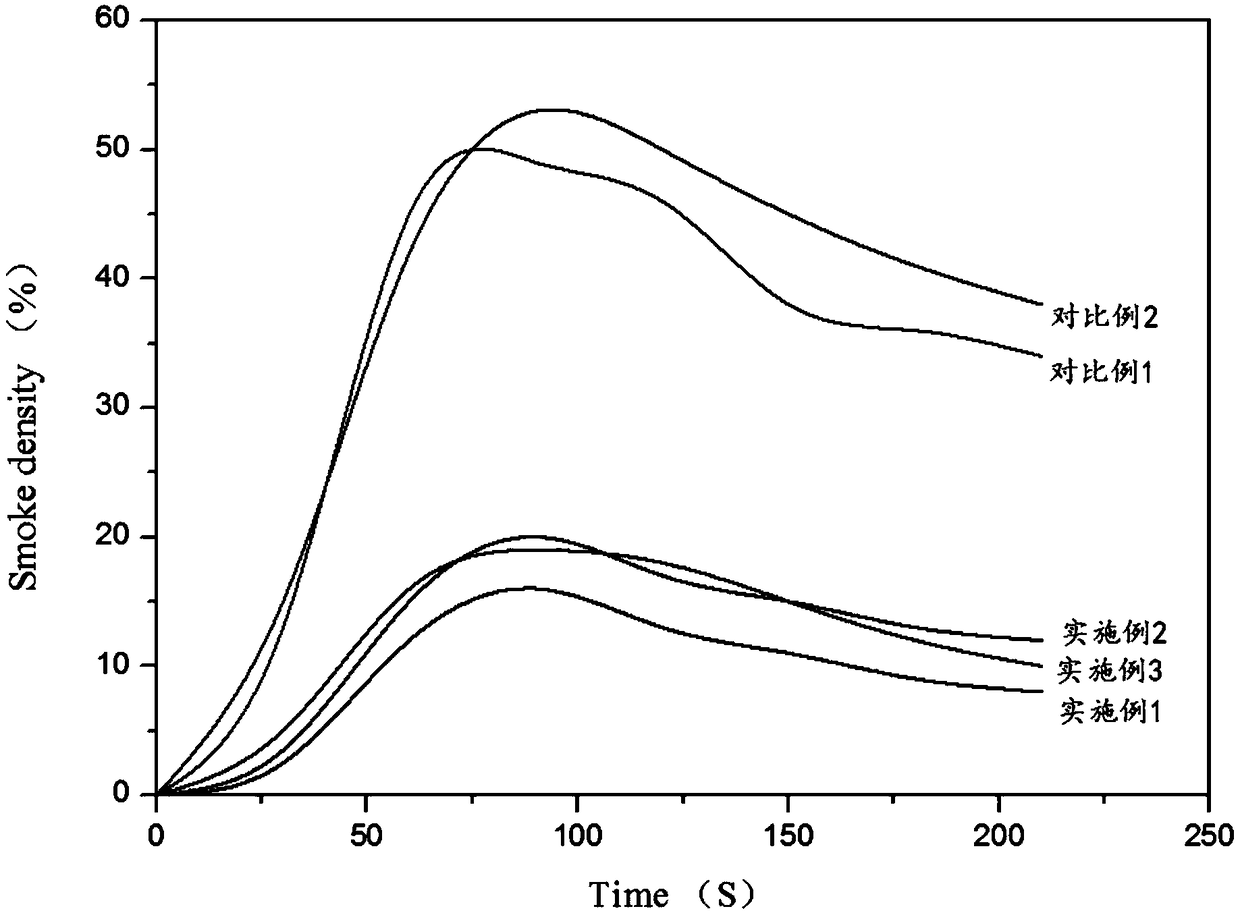

A fire-resistant coating and high-temperature-resistant technology, which is applied in fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of reducing the fire-proof performance of fire-resistant coatings, losing effective protection of internal structures, and fast heat transfer rates. Improve the flame retardant effect, inhibit the generation of smog, and inhibit the generation of volatile degradation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

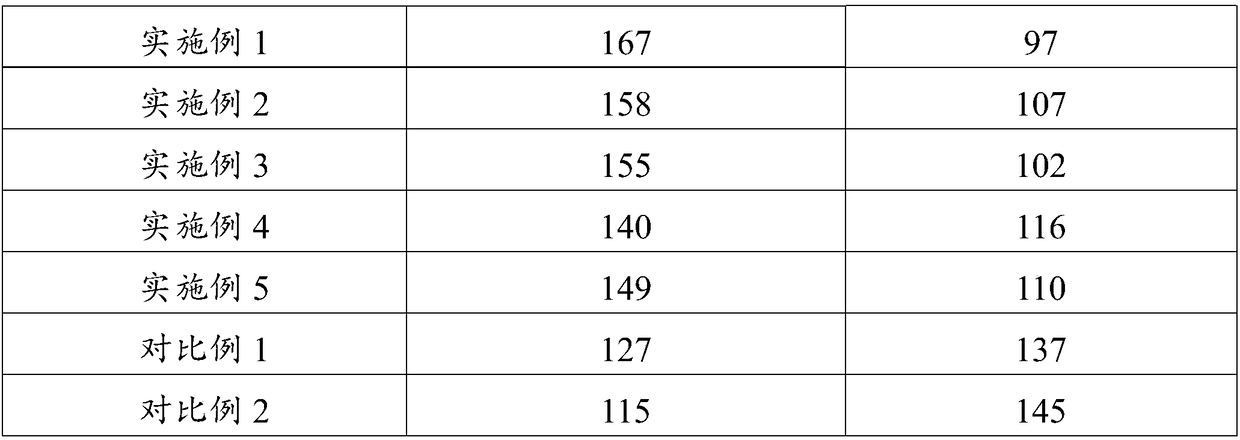

Examples

Embodiment 1

[0031] As an embodiment of the high temperature resistant fireproof coating of the present invention, the high temperature resistant fireproof coating described in this embodiment includes the following components by mass: 15 parts of acrylic emulsion, 20 parts of water-based polyurethane, 25 parts of epoxy resin, 10 parts of wall carbon nanotubes, 0.6 parts of graphene oxide, 1.3 parts of modified nano hollow silica microspheres, 32 parts of composite intumescent flame retardant, 14 parts of melamine, 15 parts of pentaerythritol, 9 parts of potassium silicate, 6 parts of bentonite parts, 0.8 parts of additives and 50 parts of water, wherein the composite intumescent flame retardant is composed of melamine phosphate, ammonium polyphosphate and nanometer ferric oxide, and the mass of melamine phosphate, ammonium polyphosphate and nanometer ferric oxide The ratio is 1:1.2:0.12.

[0032] The preparation method of high temperature resistant fireproof coating described in the prese...

Embodiment 2

[0040] As an embodiment of the high temperature resistant fireproof coating of the present invention, the high temperature resistant fireproof coating described in this embodiment comprises the following components by mass: 30 parts of acrylic emulsion, 20 parts of water-based polyurethane, 18 parts of epoxy resin, 10 parts of wall carbon nanotubes, 0.5 parts of graphene oxide, 1.4 parts of modified nano hollow silica microspheres, 36 parts of composite intumescent flame retardant, 17 parts of melamine, 16 parts of pentaerythritol, 6 parts of potassium silicate, 10 parts of bentonite parts, 2.4 parts of additives and 60 parts of water, wherein the composite intumescent flame retardant includes melamine phosphate, ammonium polyphosphate and nanometer ferric oxide, the mass ratio of melamine phosphate, ammonium polyphosphate and nanometer ferric oxide It is 1:1.5:0.18.

[0041] The preparation method of high temperature resistant fireproof coating described in the present embodi...

Embodiment 3

[0049] As an embodiment of the high temperature resistant fireproof coating of the present invention, the high temperature resistant fireproof coating described in this embodiment includes the following components by mass: 25 parts of acrylic emulsion, 35 parts of waterborne polyurethane, 10 parts of epoxy resin, more 10 parts of wall carbon nanotubes, 0.6 parts of graphene oxide, 1.2 parts of modified nano hollow silica microspheres, 38 parts of composite intumescent flame retardant, 18 parts of melamine, 18 parts of pentaerythritol, 5 parts of potassium silicate, 7 parts of bentonite parts, 1.5 parts of additives and 58 parts of water, wherein the composite intumescent flame retardant includes melamine phosphate, ammonium polyphosphate and nanometer ferric oxide, the mass ratio of melamine phosphate, ammonium polyphosphate and nanometer ferric oxide It is 1:2:0.18.

[0050] The preparation method of high temperature resistant fireproof coating described in the present embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com