ABS material and preparation method thereof

A technology of ABS material and ABS resin, which is applied in the field of ABS materials, can solve the problems of limiting the application of ABS materials, difficulty in balancing weather resistance and mechanical properties, etc., to improve light aging resistance, improve processing stability, improve weather resistance and mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

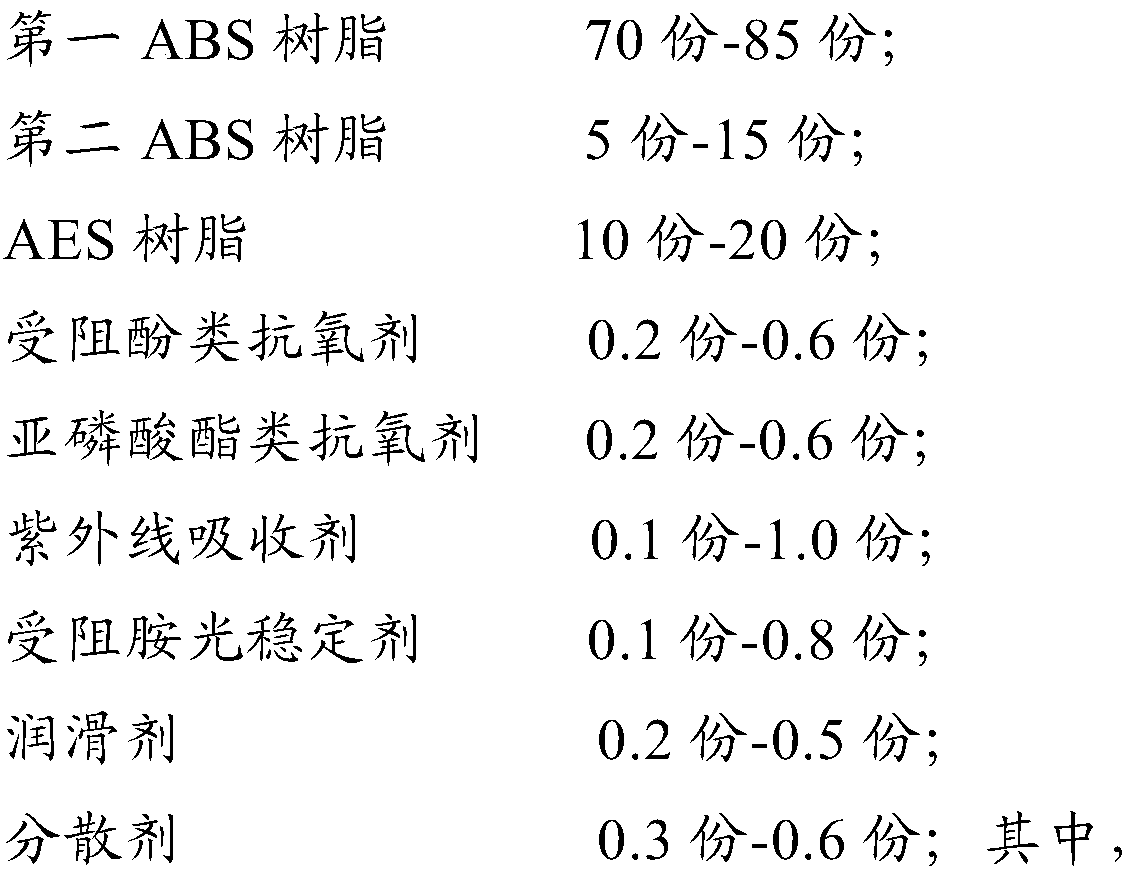

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the disclosed ABS material comprises the following steps:

[0043] Step (1) Weighing raw materials in proportion.

[0044] Step (2) Put the first ABS resin, the second ABS resin, the AES resin and the dispersant into the mixer in sequence and stir evenly to obtain a premix. The sequential mixing of the first ABS resin, the second ABS resin, the AES resin and the dispersant is beneficial to ensure the mixing uniformity of each raw material. The stirring time in step (2) can be 2min-10min. Further, the stirring time in step (2) may be 5min-7min.

[0045] Step (3) adding the remaining raw materials into the obtained premixed material and stirring evenly to obtain the mixed material. After the preparation of the premix, the preparation of the mixture can effectively avoid the problem of uneven mixing of powdery raw materials and other types of original materials, thereby ensuring the uniform mixing of each raw material, which is conducive to obt...

Embodiment 1

[0050] (1) In parts by weight, weigh 75 parts of the first ABS resin, 12.5 parts of the second ABS resin, 12.5 parts of AES resin, 0.2 part of hindered phenolic antioxidant 1010, 0.2 part of phosphite antioxidant 168 , 0.1 part of UV absorber UV-327, 0.1 part of UV absorber UV-P, 0.1 part of hindered amine light stabilizer UV-770, 0.3 part of lubricant EBS, 0.4 part of dispersant silicone oil;

[0051] (2) Put the first ABS resin, the second ABS resin, the AES resin and the dispersing agent into the mixer in sequence and stir for 5 minutes to obtain the premix;

[0052] (3) Add the rest of the raw materials into the premix and stir for 8 minutes to obtain a homogeneous mixture;

[0053] (4) Feed the obtained mixture into a twin-screw extruder, and obtain ABS material A1 through melting, extrusion, water cooling, air-drying, and cutting into pellets, wherein the temperature zone of the twin-screw extruder is set at 180° C., 190° C. °C, 200 °C, 210 °C, 220 °C, 230 °C, 230 °C, 2...

Embodiment 2

[0055] (1) In parts by weight, weigh 75 parts of the first ABS resin, 12.5 parts of the second ABS resin, 12.5 parts of AES resin, 0.2 part of hindered phenolic antioxidant 1010, 0.2 part of phosphite antioxidant 168 , 0.3 parts of UV absorber UV-327, 0.3 parts of UV absorber UV-P, 0.3 parts of hindered amine light stabilizer UV-770, 0.3 parts of lubricant EBS, 0.4 parts of dispersant silicone oil;

[0056] (2) Put the first ABS resin, the second ABS resin, the AES resin and the dispersing agent into the mixer in sequence and stir for 5 minutes to obtain the premix;

[0057] (3) adding the rest of the raw materials into the obtained premix and stirring for 8 minutes to obtain a homogeneous mixture;

[0058] (4) Feed the obtained mixture into a twin-screw extruder, and obtain weather-resistant ABS material A2 through melting, extrusion, water cooling, air-drying, and pelletizing, wherein the temperature zone of the twin-screw extruder is set at 180°C, 190°C, 200°C, 210°C, 220°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com