Method for continuously producing tri(tribromophenoxyl)triazine and production equipment used in method

A tribromophenoxy, production equipment technology, applied in chemical instruments and methods, mixers, organic chemistry and other directions, can solve the problem of slow reaction speed of cyanuric chloride and tribromophenol, unable to realize continuous operation, increase production Cost and other issues, to achieve the effect of stable process and product quality, conducive to the conversion of old and new kinetic energy, and convenient filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

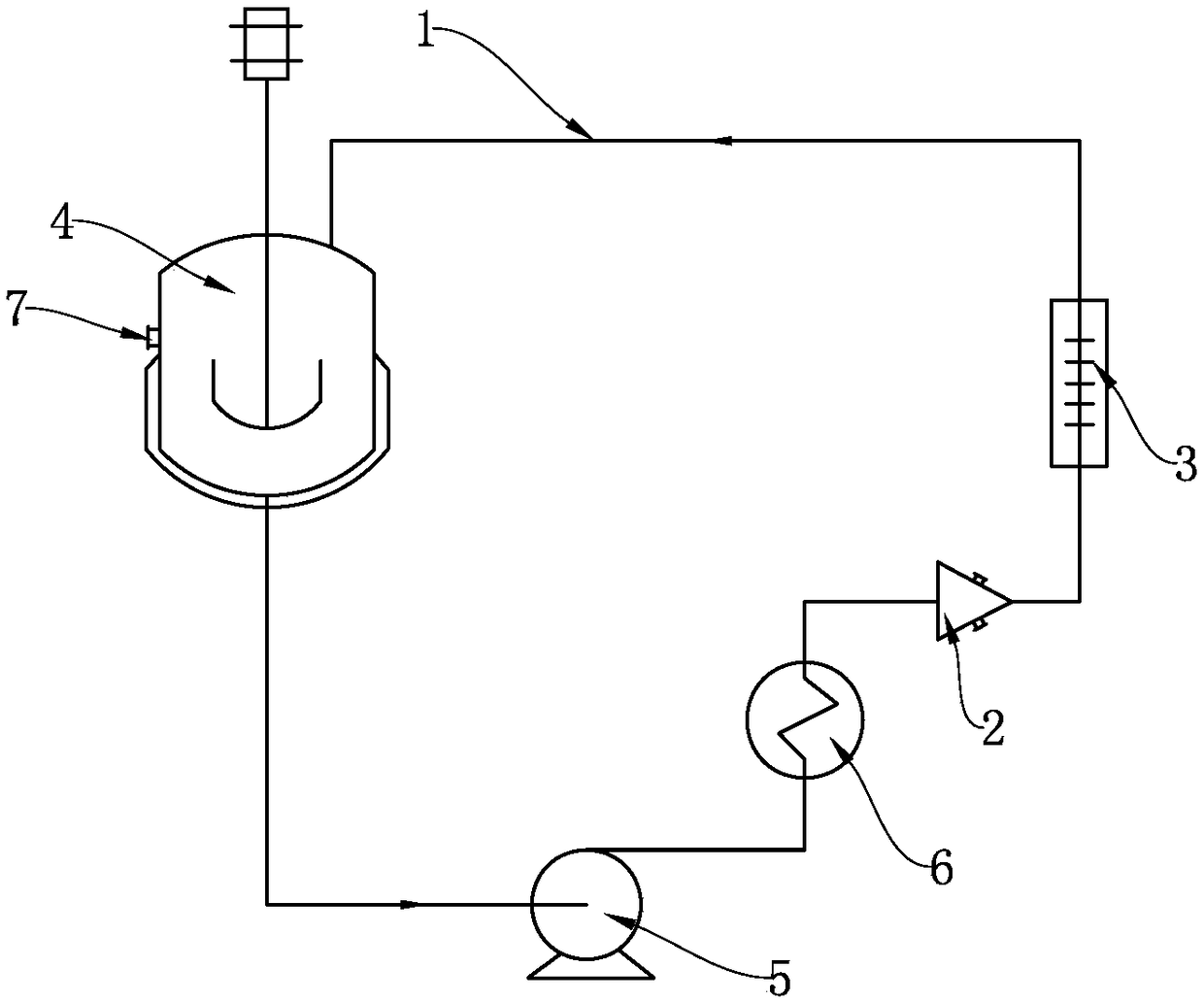

[0038] On the DN40 tetrafluoroethylene-lined circulation pipeline, the reactor, the transfer pump, the cooler, the two-inlet jet, and the tubular packing mixer are respectively set up, and the overflow port is set on the upper part of the reactor, and the loop of the circulating pipeline is connected to the bottom of the reactor. . 500L of chloroform was added into the reaction kettle.

[0039] Preparation of organic phase (I): 200 kg (1.084 mol) of cyanuric chloride was completely dissolved in 2000 L of chloroform, and the temperature was lowered to 10°C.

[0040] Preparation of aqueous phase (II): 1105 kg (3.340 mol) of tribromophenol and 140 kg (3.499 mol) of sodium hydroxide were reacted and dissolved in 1800 kg of water, and 10 kg (0.054 mol) of trimethylbenzyl ammonium chloride was added. ) dissolved and cooled to 10°C.

[0041]The organic phase (I) and the water phase (II) are connected with the side buckles of the two inlet ejectors respectively, open the chiller inl...

Embodiment 2

[0043] The difference as in Example 1 is that chloroform is replaced with an equal volume of chlorobenzene; the temperature of the reaction kettle is 85°C. Finally, the yield of the product is 98.5%, and the melting point of tris(tribromophenoxy)triazine is 227.8-233.9°C after detection.

Embodiment 3

[0045] Unlike Example 1, the raw material mixer was replaced with a Kenics mixer. Other conditions remain unchanged. Finally, the yield of the product is 98.6%, and the melting point of tris(tribromophenoxy)triazine is 228.5-235.9°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com