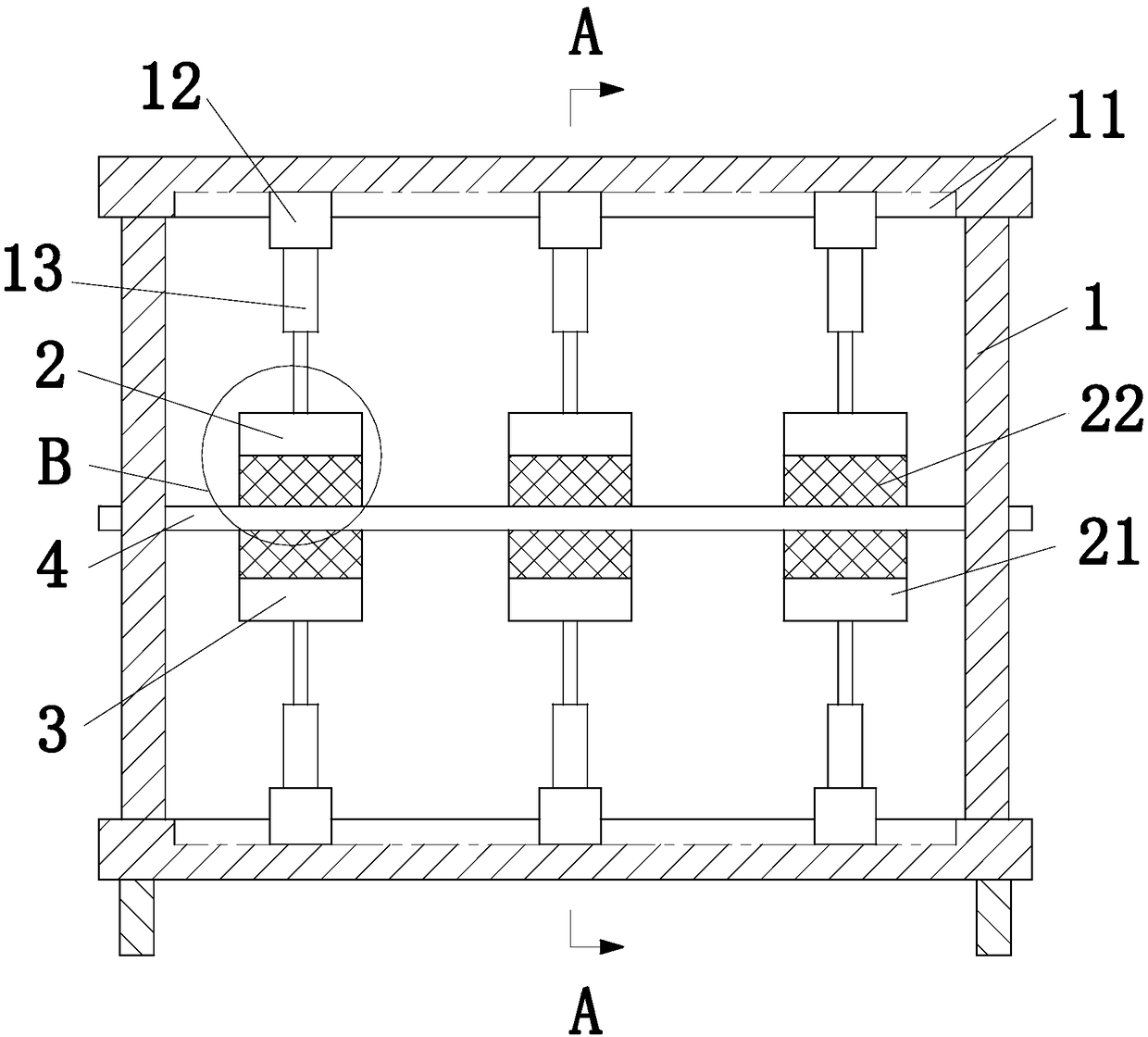

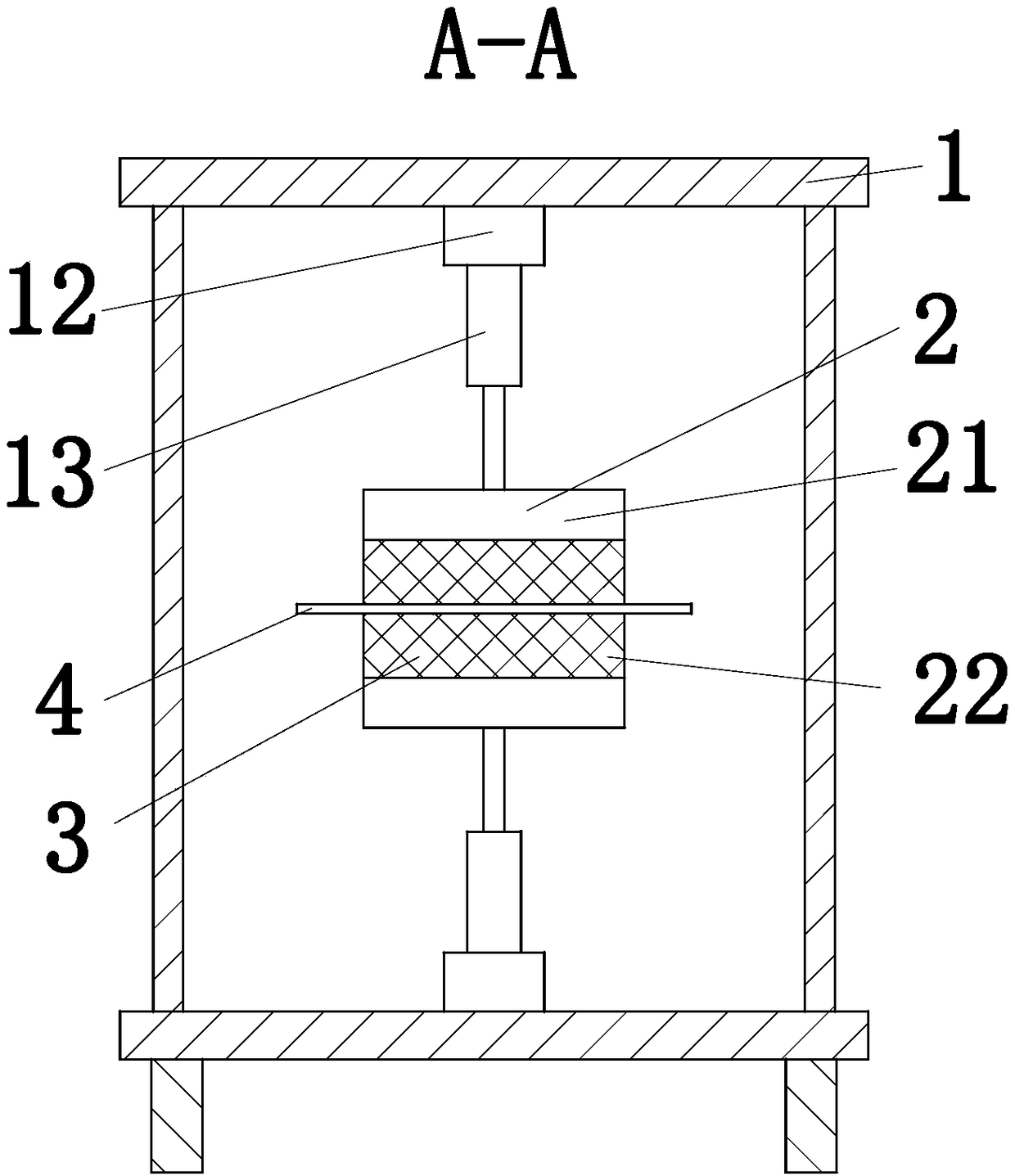

Lead-acid storage battery plate dust removing device

A lead-acid battery and cleaning device technology, applied in the direction of lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction, etc., can solve the problems of use restrictions, inability to clean battery plate dust, etc., to improve dust removal efficiency and improve cleaning. effect, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

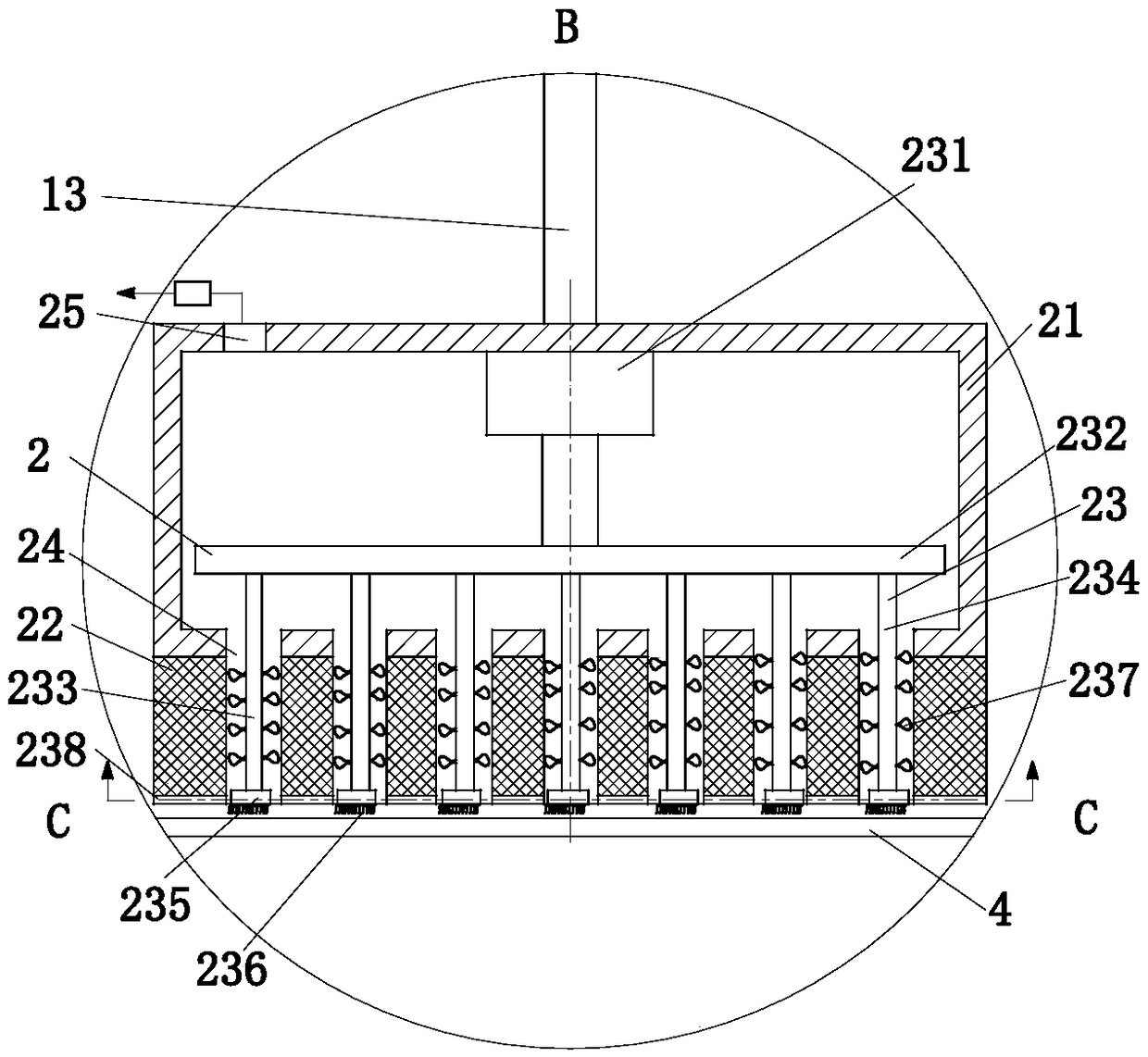

[0025] As an embodiment of the present invention, the No. 1 cleaning unit 23 includes a No. 2 pneumatic cylinder 231, a fixed plate 232, and a No. 1 dust removal unit 233; the No. 2 pneumatic cylinder 231 is fixedly installed in the middle of the top of the sealed chamber 21; The bottom of the No. 2 pneumatic cylinder 231 is fixedly equipped with a fixed plate 232; the bottom of the fixed plate 232 is rotated and installed with a No. 1 dust removal unit 233; the No. 1 dust removal unit 233 includes a guide rod 234, a dust removal fixed plate 235 and a dust removal brush 236 The dust removal fixed plate 235 is located in the dust removal channel 24; the top of the dust removal fixed plate 235 is fixedly equipped with a guide rod 234; the guide rod 234 is connected with the fixed plate 232 in rotation; Hairbrush 236; No. 1 dedusting unit 233 is under the effect of No. 2 pneumatic cylinder 231, makes No. 1 dedusting unit 233 expand and contract in dust removal channel 24, and duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com