Hybrid-feeding slot array antenna

A technology of slot array antenna and coupling feeding, which is applied in the direction of separately powered antenna array, antenna, antenna array, etc., can solve the problem of high processing cost, low utilization rate of substrate-integrated waveguide antenna, and difficult-to-multilayer substrate-integrated waveguide Structure and other issues, to achieve the effect of high processing precision, low cost, high antenna gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The hybrid feeding slot array antenna of the present invention works in the Ka band, mainly including 40 substrate integrated waveguides, 220 radiation slots, 40 coupling feeding slots, power division and difference network, antenna and beam port, antenna difference beam port.

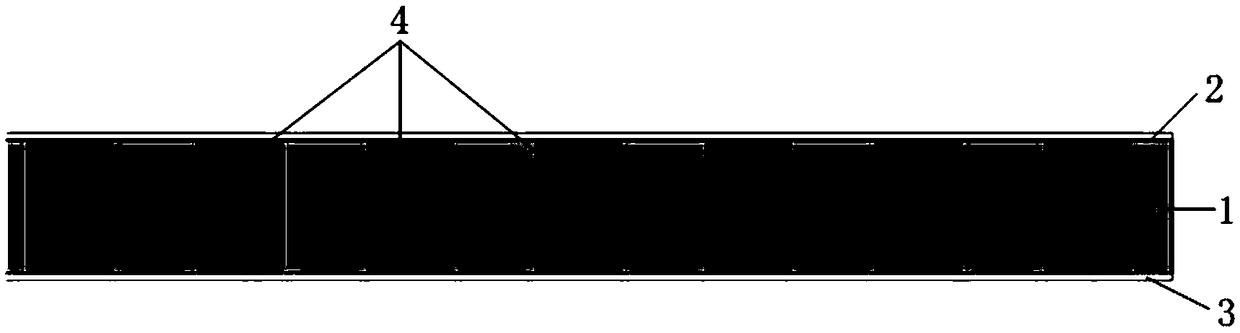

[0032] refer to figure 1 and figure 2 , the radiation front is a double-sided copper-clad printed board, using a substrate-integrated waveguide structure, a dielectric substrate 1, a metal layer 2 on the front side of the dielectric substrate, a metal layer 3 on the back side of the dielectric substrate, and a metallized through-hole array 4 penetrating the dielectric substrate. Multiple substrate integrated waveguides. The dielectric board is Rogers 5880, with a relative dielectric constant of 2.2 and a thickness of 0.787mm. The thickness of the upper and lower metal layers is 0.035mm. The diameter of the metallized through hole is 0.5mm, and the distance between adjacent through holes is 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com