Preparation method of finishing agent for shoe upper fabric

A technology for fabric finishing agent and shoe upper, which is applied in fiber treatment, biochemical fiber treatment, textile and papermaking, etc., can solve the problems of destroying the appearance and style of shoe materials, difficulty in washing, etc., to improve self-cleaning effect, good air permeability and waterproof performance, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

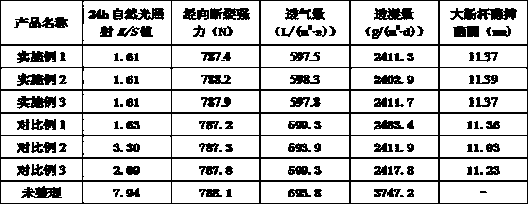

Examples

Embodiment 1

[0031] A preparation method of a shoe upper fabric finishing agent, the components are calculated by weight, comprising the following steps:

[0032] (1) Take 20 parts of camphor tree wood powder, add 100 parts of phenylethanol solution with a volume ratio of 2:1 for Soxhlet extraction, remove the extract, and treat with sodium chlorite at pH 4, 75°C for 5 hours , and then treated with 2wt% potassium oxide at 90°C for 2h;

[0033] (2) Treat with sodium chlorite at pH 4 for 1 hour, then treat with 5 wt% potassium oxide at 90°C for 2 hours;

[0034] (3) After treatment with 1% hydrochloric acid solution, add 50ml of deionized water, place it in an ultrasonic plant cell pulverizer for ultrasonic treatment, the ultrasonic power is 1200W, and the ultrasonic time is 30min;

[0035] (4) After freeze-drying, add 10 parts of dimethyl sulfoxide, and pass through a high-speed pulverizer at a speed of 6×10 3 Cut at rpm for 20 min;

[0036] (5) Add 0.5 part of isomeric decanol polyoxyet...

Embodiment 2

[0044] A preparation method of a shoe upper fabric finishing agent, the components are calculated by weight, comprising the following steps:

[0045] (1) Take 30 parts of camphor tree wood powder, add 130 parts of phenylethanol solution with a volume ratio of 2:1 for Soxhlet extraction, remove the extract, and use sodium chlorite at pH 4.5, 75 ° C Treat for 5.5h, then treat with 2wt% potassium oxide at 90°C for 2.5h;

[0046] (2) Treat with sodium chlorite at pH 4.5 for 1 hour, then treat with 5wt% potassium oxide at 90°C for 2.5 hours;

[0047] (3) After treatment with 1% hydrochloric acid solution, add 65ml of deionized water, place it in an ultrasonic plant cell pulverizer for ultrasonic treatment, the ultrasonic power is 1200W, and the ultrasonic time is 30min;

[0048] (4) After freeze-drying, add 15 parts of dimethyl sulfoxide, and pass through a high-speed pulverizer at a speed of 6×10 3 Cut at rpm for 23min;

[0049] (5) Add 0.8 parts of isomeric decanol polyoxyethy...

Embodiment 3

[0057] A preparation method of a shoe upper fabric finishing agent, the components are calculated by weight, comprising the following steps:

[0058] (1) Take 40 parts of camphor tree wood powder, add 150 parts of phenylethanol solution with a volume ratio of 2:1 for Soxhlet extraction, remove the extract, and treat with sodium chlorite at pH 5, 75°C for 6 hours , and then treated with 2wt% potassium oxide at 90°C for 3h;

[0059] (2) Treat with sodium chlorite at pH 5 for 1 hour, then treat with 5 wt% potassium oxide at 90°C for 3 hours;

[0060] (3) After treatment with 1% hydrochloric acid solution, add 80ml of deionized water, place it in an ultrasonic plant cell pulverizer for ultrasonic treatment, the ultrasonic power is 1200W, and the ultrasonic time is 30min;

[0061] (4) After freeze-drying, add 20 parts of dimethyl sulfoxide, and pass through a high-speed pulverizer at a speed of 6×10 3 Cut at rpm for 25 min;

[0062] (5) Add 1 part of isomeric decanol polyoxyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com