A kind of helical nano carbon fiber and preparation method thereof

A nano-carbon fiber and helical technology, which is applied in the field of helical nano-carbon fiber and its preparation, can solve the problems of inability to realize mass production, complex preparation process, low yield, etc., and achieve controllable process preparation, increase growth, and high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

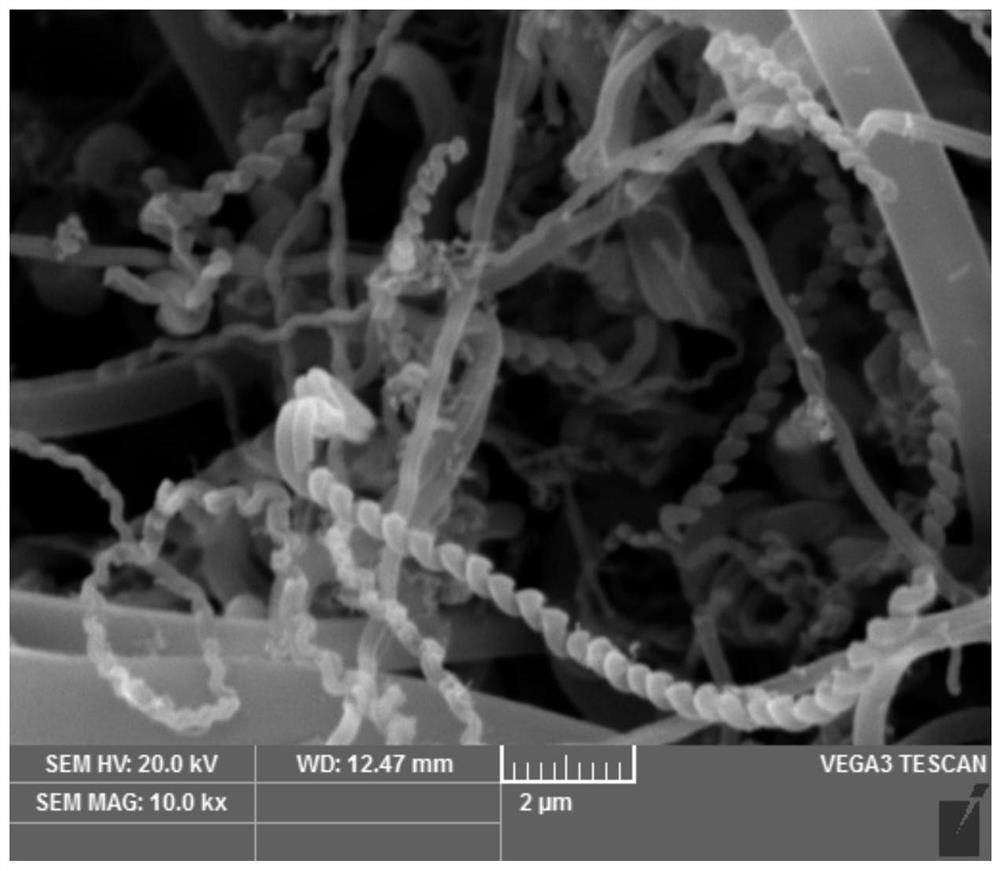

Image

Examples

Embodiment 1

[0041] The preparation method of the helical carbon nanofiber of the present embodiment comprises:

[0042] 1. Preparation of nanoporous nickel phosphorus materials:

[0043] (11) Preparation of plating solution:

[0044] (1.1) Preparation of modified carbon black: place carbon black in concentrated nitric acid and heat in an oil bath at 80° C., condense and reflux, and stir for 20 hours to prepare modified carbon black. Cool to room temperature, centrifuge and wash to neutral, then dry for use.

[0045] (1.2) Prepare the first solution: mix lactic acid, nickel sulfate and citric acid to prepare the first solution. Specifically, take lactic acid in a beaker, add 100ml of distilled water and mix thoroughly, then weigh nickel sulfate into the beaker, add citric acid while stirring continuously with a glass rod, until the nickel sulfate is completely dissolved to form a uniform transparent solution, and the first solution is prepared.

[0046] (1.3) Prepare the second solution...

Embodiment 2

[0058] The preparation method of the helical carbon nanofiber of the present embodiment comprises:

[0059] 1. Preparation of nanoporous nickel phosphorus materials:

[0060] (11) Preparation of plating solution:

[0061] (1.1) Preparation of modified carbon black: place carbon black in concentrated nitric acid and heat in an oil bath at 100° C., condense and reflux, and stir for 15 hours to prepare modified carbon black. Cool to room temperature, centrifuge and wash to neutral, then dry for use.

[0062] (1.2) Prepare the first solution: mix lactic acid, nickel sulfate and citric acid to prepare the first solution. Specifically, take lactic acid in a beaker, add 100ml of distilled water and mix thoroughly, then weigh nickel sulfate into the beaker, add citric acid while stirring continuously with a glass rod, until the nickel sulfate is completely dissolved to form a uniform transparent solution, and the first solution is prepared.

[0063] (1.3) Prepare the second solutio...

Embodiment 3

[0075] The preparation method of the helical carbon nanofiber of the present embodiment comprises:

[0076] 1. Preparation of nanoporous nickel phosphorus materials:

[0077] (11) Preparation of plating solution:

[0078] (1.1) Preparation of modified carbon black: carbon black was placed in concentrated nitric acid and heated in an oil bath at 90° C., condensed and refluxed, stirred and reacted for 18 hours to prepare modified carbon black. Cool to room temperature, centrifuge and wash to neutral, then dry for use.

[0079] (1.2) Prepare the first solution: mix lactic acid, nickel sulfate and citric acid to prepare the first solution. Specifically, take lactic acid in a beaker, add 100ml of distilled water and mix thoroughly, then weigh nickel sulfate into the beaker, add citric acid while stirring continuously with a glass rod, until the nickel sulfate is completely dissolved to form a uniform transparent solution, and the first solution is prepared.

[0080] (1.3) Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com