Partial Oxygen Supplementation in Side Blowing Reduction Furnace to Reduce Lead Content in Slag

A reduction furnace and oxygen supplement technology, which is applied in furnaces, charge materials, crucible furnaces, etc., can solve the problems of inability to adjust the redox atmosphere in local side-blown reduction furnaces, and high lead content in the slag, and achieve high slag temperature and fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

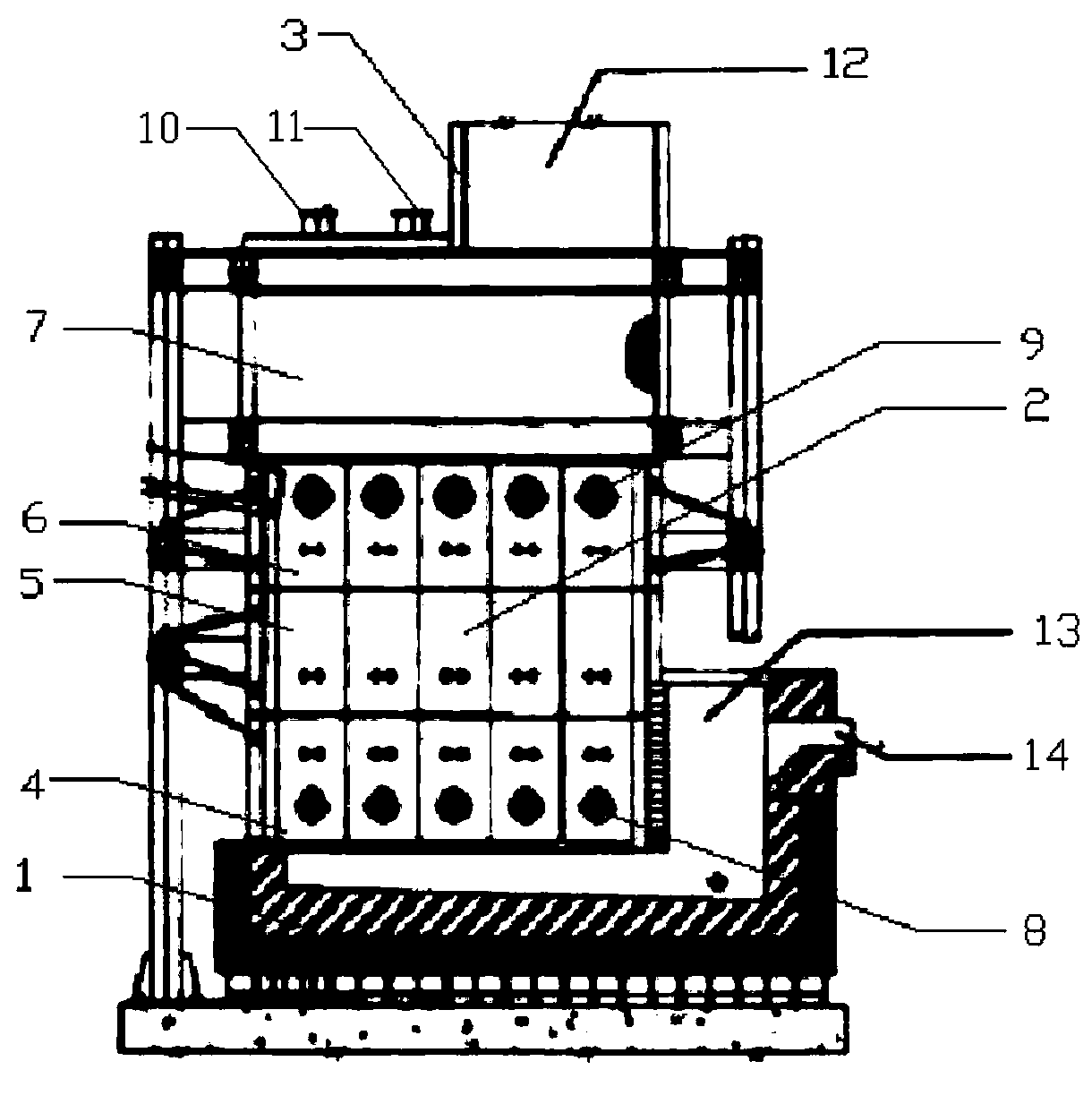

[0028] combine figure 1 and figure 2 , the structure of the side-blowing reduction furnace used in this embodiment is: it is composed of a hearth 1, a furnace body 2, and a furnace roof 3; the hearth 1 is made of refractory materials, and the part above the hearth is the furnace body 2. Furnace body 2 is spliced by one layer of steel water jacket and three layers of copper water jacket. From bottom to top, it is the first layer of copper water jacket 4, the second layer of copper water jacket 5, the third layer of copper water jacket 6 and Steel water jacket 7; several primary tuyeres 8 are provided on both sides of the first layer of copper water jacket of the furnace body, which are used to blow oxygen-enriched air into the molten slag layer; The secondary tuyere 9 is used to blow a certain amount of air into the furnace to fully burn the combustible gas such as CO in the flue gas; the part above the three-layer copper water jacket and the furnace top are composed of a m...

Embodiment 2

[0037] The structure of the side-blowing reduction furnace used in this embodiment is the same as that in Embodiment 1.

[0038] The method for reducing the lead content in the slag by supplementing oxygen locally in the side-blowing reduction furnace includes the following steps:

[0039] (1) Oxygen control in the furnace:

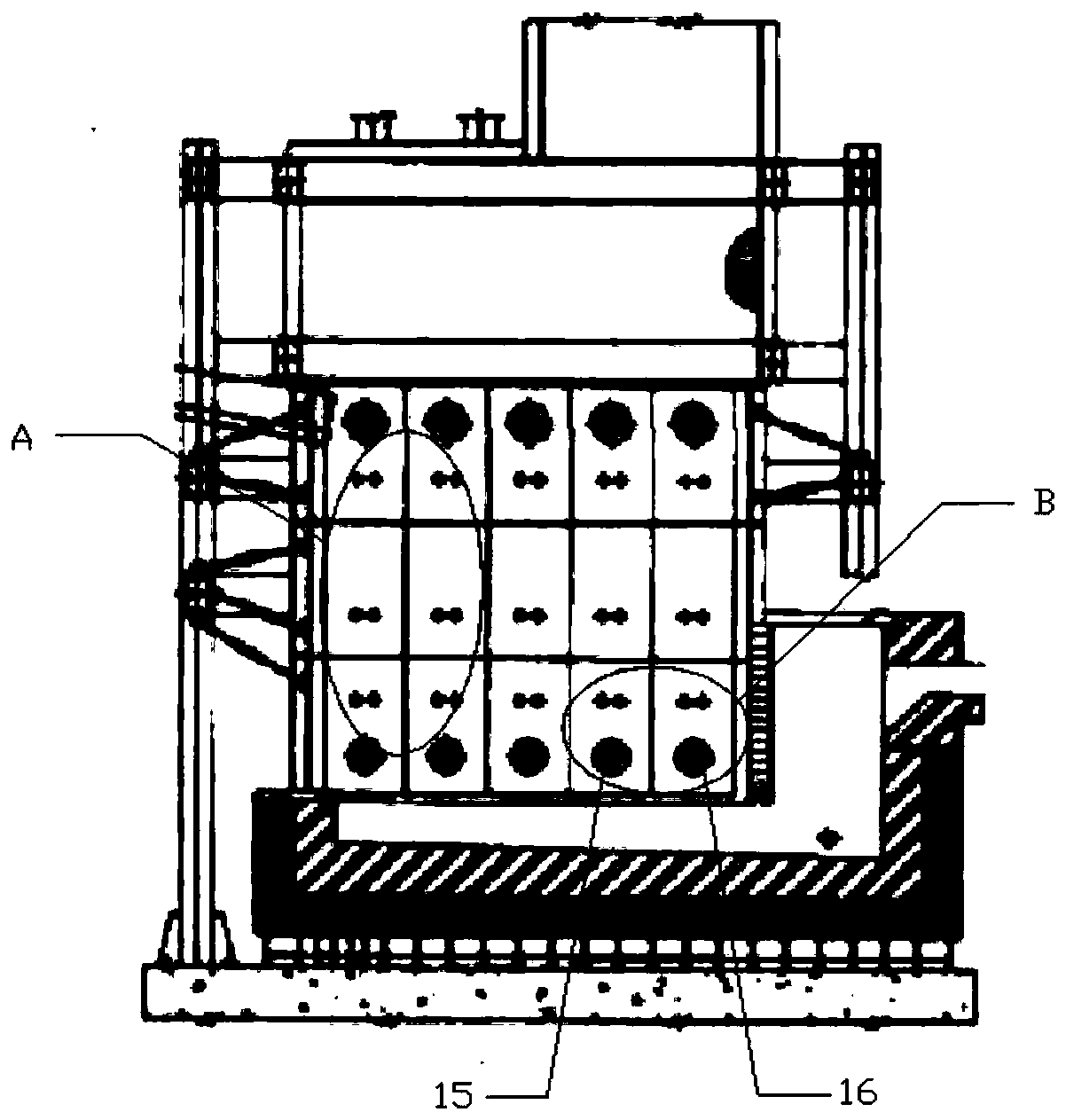

[0040] Put the material and fuel into the side-blown reduction furnace, and supply oxygen to the side-blown reduction furnace through the supply pipe of the side-blown reduction furnace, that is, the primary tuyere 8 and the secondary tuyere 9, to control the overall oxygen quality in the furnace. The content is 62%; then connect the pure oxygen pipeline to supply oxygen from the two side tuyeres below the coal particle feed port, and control the oxygen mass concentration in the lower coal tuyere area A to be 75%;

[0041] (2) Temperature regulation:

[0042] After controlling the overall oxygen mass percentage in the furnace to 62%, adjust the input am...

Embodiment 3

[0046] The structure of the side-blowing reduction furnace used in this embodiment is the same as that in Embodiment 1.

[0047] The method for reducing the lead content in the slag by supplementing oxygen locally in the side-blowing reduction furnace includes the following steps:

[0048] (1) Oxygen control in the furnace:

[0049]Put the material and fuel into the side-blown reduction furnace, and supply oxygen to the side-blown reduction furnace through the supply pipe of the side-blown reduction furnace, that is, the primary tuyere 8 and the secondary tuyere 9, to control the overall oxygen quality in the furnace. The content is 64%; then connect the pure oxygen pipeline to supply oxygen from the two side air outlets below the coal particle inlet, and control the oxygen mass concentration in the lower coal air outlet area A to be 74%;

[0050] (2) Temperature regulation:

[0051] After controlling the overall oxygen mass percentage in the furnace to 64%, adjust the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com