Method for controlling circulating furnace number of decarburization slag in less slag smelting process of converter

A technology for smelting and decarburizing slag with less slag is applied in controlling the number of circulating furnaces of decarburized slag in the process of reducing slag smelting in converters, and in the field of converter smelting molten steel. The effect of sexual security, consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

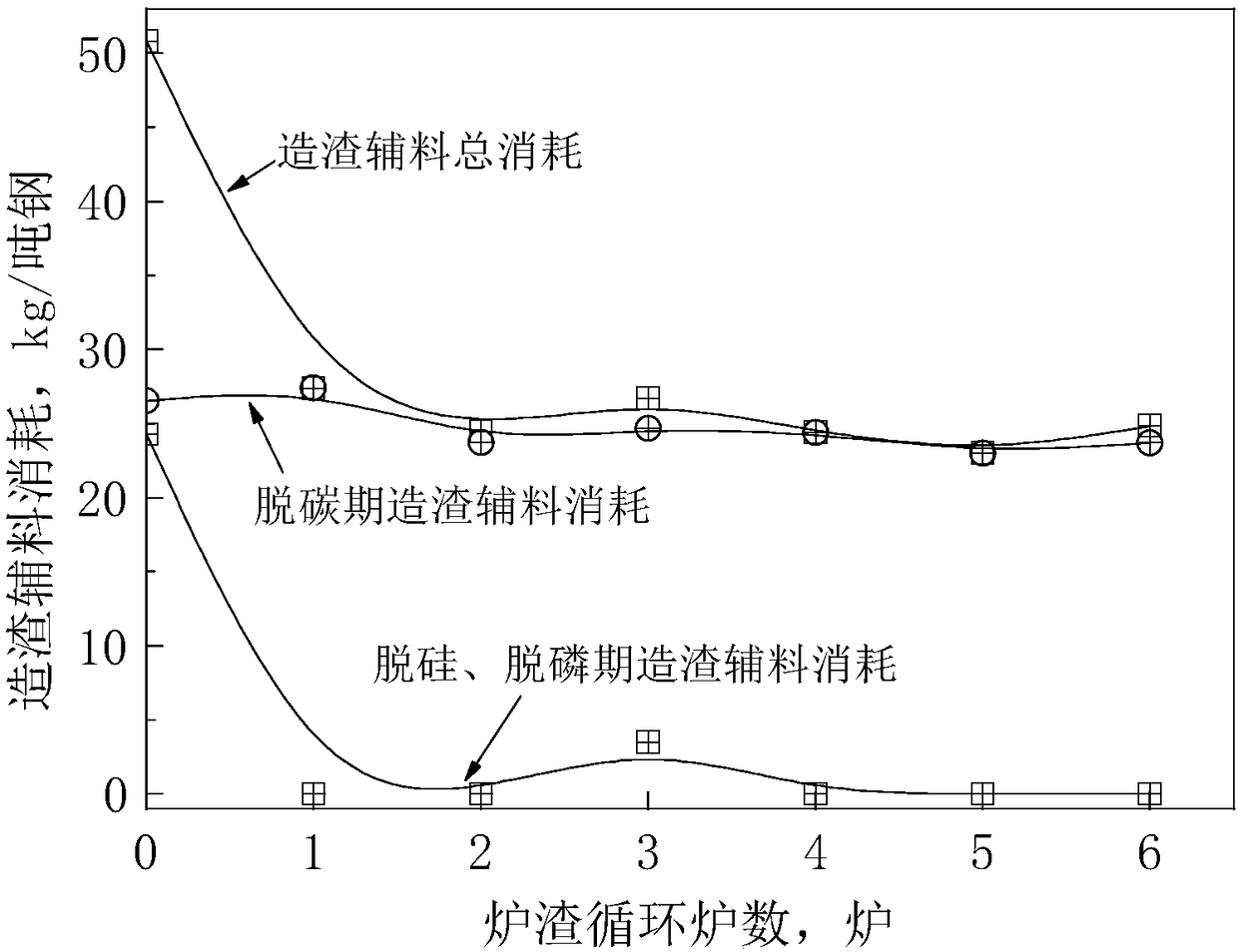

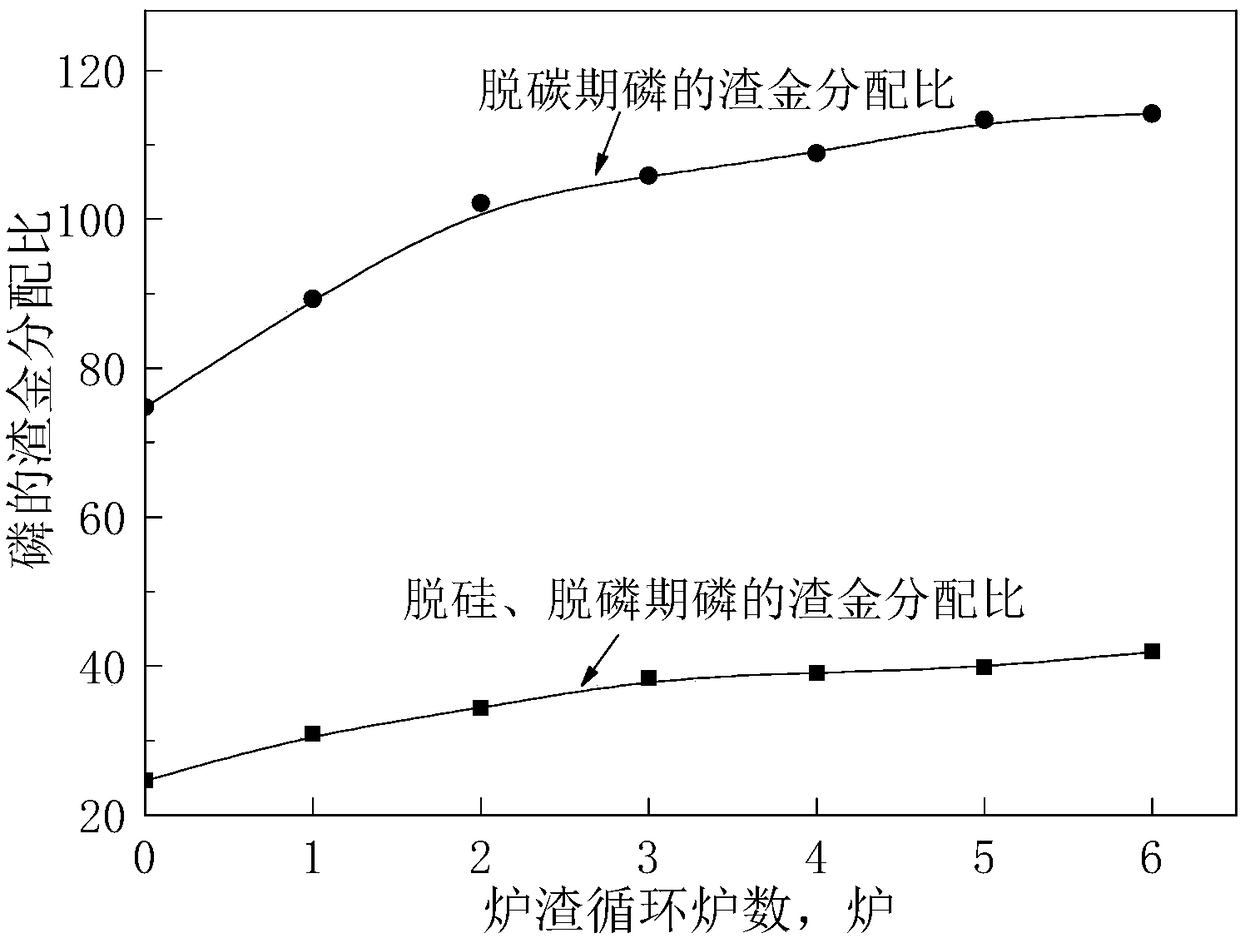

[0022] As in the embodiments shown in Table 1 to Table 4, taking the 150-ton top-bottom combined blowing converter smelting grade as 340CQ-1 automobile inner plate steel as an example, the bottom blowing gas in the converter smelting process is argon; Blowing converter adopts converter less slag smelting process for steelmaking, including the following steps: adding scrap steel, mixing molten iron → converter desiliconization, dephosphorization → dephosphorization slag in the early stage → blowing decarburization and heating → converter tapping → leaving decarburization slag and recycled to the next furnace.

[0023] Table 1 Parameters of converter smelting metal material in the embodiment of the present invention

[0024]

[0025]

[0026] Table 2 Converter smelting desiliconization and dephosphorization stage blowing process parameters of the embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com