Method for preparing high-grade metallic iron and titanium-rich slag with titanium concentrate as raw material

A high-grade titanium concentrate technology, applied in furnaces, furnace types, fluidized bed furnaces, etc., to achieve the effects of small investment scale, shortened smelting time, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

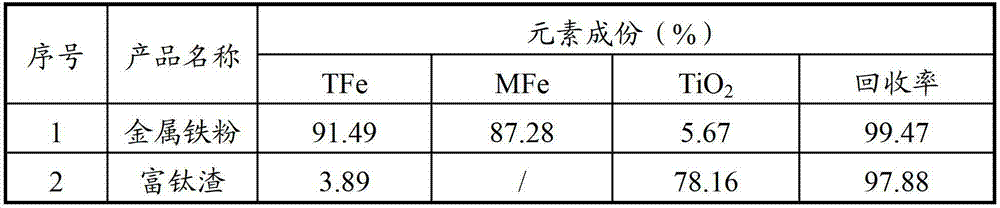

Examples

Embodiment 1

[0030] The tunnel kiln is used as the main equipment in the reduction process, and titanium concentrate powder is used as raw material to produce high-grade metal iron powder and titanium-rich slag through reduction and separation:

[0031] 1) The proposed index of the product obtained after reduction:

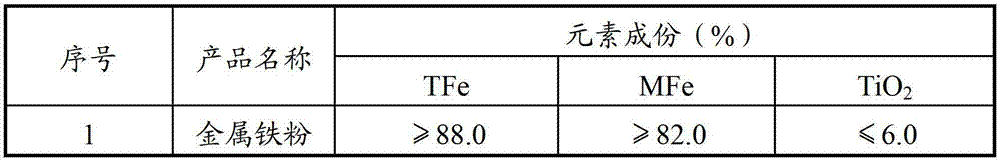

[0032] ① Metal iron powder products:

[0033]

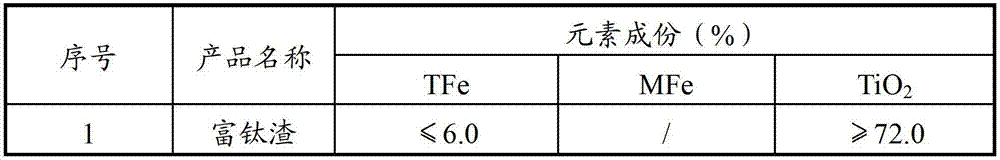

[0034] ②Titanium-rich slag products:

[0035]

[0036] 2) Production process

[0037] (1) Selection of raw materials:

[0038] The main composition indicators of the reduced material titanium concentrate are as follows: TFe=33.27%, TiO 2 =47.56%; the particle size ≤ -200 reached 92%.

[0039] Iron scale index: TFe=71.8%, particle size: 91% below -200 mesh.

[0040] Bituminous coal powder: C=84.54%, ash=4.77%, volatile matter=10.69%, particle size≤-160 mesh.

[0041] Auxiliary (industrial product): Glauber's salt: Na 2 SO 4 , Soda ash: Na 2 CO 3 1. Industrial salt: NaCl, ground into -160 mesh powder.

[0042] (2) ...

Embodiment 2

[0052] BLT-I reduction kiln is used as the main equipment in the reduction process, and titanium concentrate powder is used as raw material to produce high-grade metal iron powder and titanium-rich slag through reduction and separation:

[0053] 1) The proposed index of the product obtained after reduction:

[0054] ① Metal iron powder products:

[0055]

[0056] ②Titanium-rich slag products:

[0057]

[0058] 2) Production process

[0059] (1) Selection of raw materials

[0060] The main composition indicators of the reduced material titanium concentrate are as follows: TFe=32.17%, TiO 2 =47.46%; the particle size ≤ -200 aims to reach 93%.

[0061] Iron scale index: TFe=71.5%, particle size: 91% below -200 mesh.

[0062] Bituminous coal powder: C=84.92%, ash=4.57%, volatile matter=10.51%, particle size≤-160 mesh.

[0063] Auxiliary (industrial product): Glauber's salt: Na 2 SO 4 , Soda ash: Na 2 CO 3 1. Industrial salt: NaCl, ground into -160 mesh powder.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com