Oil-soluble rosemary extract and preparation method and application thereof

A rosemary extract and oil-soluble technology, which is applied to the field of oil-soluble rosemary extract and its preparation, can solve the problems of affecting the use effect of the product, limiting the scope of application, slow dissolution, etc., and achieves good oil-soluble characteristics, flow The effect of good sex and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

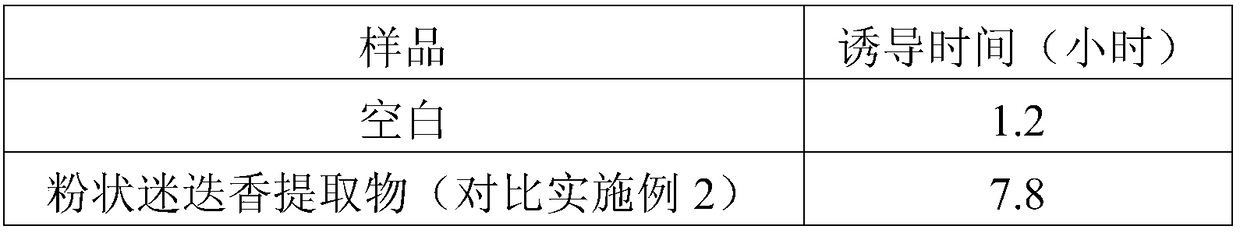

Examples

Embodiment 1

[0049] (1) get 10kg powdery rosemary extract (preparation method is with comparative example 2 step (1), wherein, carnosic acid and carnosol content add up to 25.1%) and 200kg vegetable oil extraction solvent mix, then 40 Under the condition of ℃, stir and extract at 80r / min for 30min, filter under normal pressure to obtain clear liquid;

[0050] (2) The clear liquid prepared in step (1) is concentrated under reduced pressure at 40~45°C and -0.04Mpa until there is no solvent residue, and 6.4kg of rosemary extract (carnosic acid and carnosic acid) are obtained. The grass phenol content is 31.2% in total);

[0051] (3) Place the rosemary extract extract prepared in step (2) in an emulsification kettle, preheat to 80°C, then add 6.4kg of oil-soluble emulsifier caprylic capric acid glyceride, at 80°C, 120r / Stir and emulsify for 30min under the condition of min to obtain the oil-soluble rosemary extract;

[0052] (4) Add 4.2kg of sunflower oil to the oil-soluble rosemary extract...

Embodiment 2

[0054] (1) get 10kg powdery rosemary extract (preparation method is the same as comparative example 2 step (1), wherein, carnosic acid and carnosol content add up to 22.6%) and 250kg ethyl acetate mix, then 20 ℃ Under the conditions, stirring and extracting at 180r / min for 50min, filtering under normal pressure to obtain clear liquid;

[0055](2) Concentrate the clear liquid prepared in step (1) under reduced pressure at 30~35°C and -0.06Mpa until no solvent remains, and obtain 6.2kg of rosemary extract (carnosic acid and carnosic acid) The glucophenol content is 28.4% in total);

[0056] (3) Place the rosemary extract extract prepared in step (2) in an emulsification kettle, preheat to 70°C, then add 1.32kg of oil-soluble emulsifier caprylic capric acid glyceride, at 70°C, 80r / Stir and emulsify for 60min under the condition of min to obtain the oil-soluble rosemary extract;

[0057] (4) add 5kg lard in the oil-soluble rosemary extract that step (3) makes, stir 70min under ...

Embodiment 3

[0059] (1) Get 10kg powdery rosemary extract (preparation method is the same as comparative example 2 step (1), wherein, carnosic acid and carnosol content add up to 35.7%) and 300kg ethyl acetate mix, then 50 ℃ Under heating conditions, stirring and extracting at 100r / min for 60min, filtering under reduced pressure to obtain clear liquid;

[0060] (2) Concentrate the clear liquid prepared in step (1) under reduced pressure under the conditions of 45~50°C and -0.05Mpa until no solvent remains, and obtain 6.3kg of rosemary extract (carnosic acid and carnosic acid) The grass phenol content is 45.8% in total);

[0061] (3) Put the rosemary extract prepared in step (2) in an emulsification kettle, preheat to 60°C, then add 3.15kg polyglycerol fatty acid ester, and put it under the conditions of 60°C and 180r / min Stir and emulsify for 50min to obtain the oil-soluble rosemary extract;

[0062] (4) Add 8kg of rapeseed oil to the oil-soluble rosemary extract prepared in step (3), st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com