A kind of high temperature resistant modified starch and its preparation method and application

A high-temperature and starch-resistant technology, applied in the field of petroleum drilling fluids, can solve problems affecting drilling quality and drilling costs, affecting the overall performance of drilling fluids, and weakening the filtration loss reduction effect, achieving improved temperature resistance, good salt resistance, The effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing high temperature resistant modified starch, comprising the following steps:

[0025] (1) provide the aqueous solution of grafting agent;

[0026] adjusting the pH value of the aqueous solution of the grafting agent to 6-8 by using an alkaline pH regulator to obtain a neutral solution of the grafting agent;

[0027] Mixing the neutral grafting agent solution with a crosslinking agent to obtain a modifier solution;

[0028] (2) After mixing the base starch and water, gelatinize the obtained starch milk to obtain gelatinized starch; the mass ratio of the base starch to water is (1-2): (50-100);

[0029] (3) Alternately dripping initiator and modifying agent solution into the gelatinized starch successively, a modification reaction occurs, and high temperature resistant modified starch is obtained;

[0030] The steps (1) and (2) are not in chronological order;

[0031] In parts by mass, the base starch is 1-2 parts, and the g...

Embodiment 1

[0056] The following amounts are in parts by mass. Dissolve 12 parts of acrylamide, 20 parts of 2-acrylamide-2-methylpropanesulfonic acid and 13 parts of sodium p-styrenesulfonate in 100 parts of distilled water at a stirring rate of 150r / min After the dissolution is completed, 3 parts of vinylpyrrolidone and 8 parts of dimethyl diallyl ammonium chloride are added to the solution to obtain a monomer solution; 4 parts of NaOH are formulated into an aqueous solution with a mass fraction of 15%. In an ice-water bath environment, use 15% NaOH aqueous solution to adjust the pH value of the solution to 6.0-8.0, and add 0.02 parts of N,N-methylene bisacrylamide and 0.06 parts of tripropylene glycol dienyl ester to dissolve In the liquid, the modifier solution is obtained for subsequent use;

[0057] At a stirring rate of 150r / min, add 8 parts of tapioca starch and 80 parts of distilled water into the reactor to prepare 10% starch milk, and heat the starch milk in a water bath at 80°C...

Embodiment 2

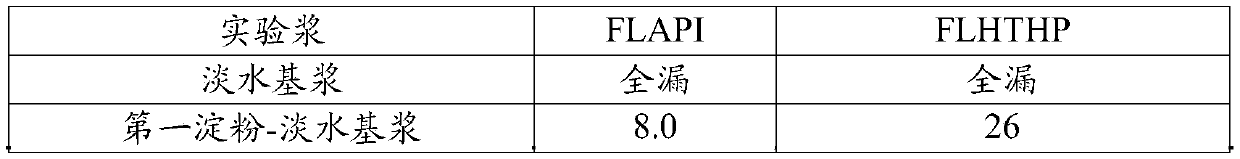

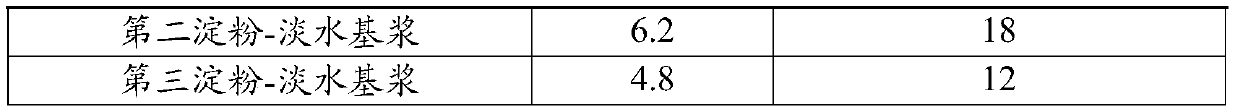

[0061] The high temperature resistant modified starch prepared in Example 1 was added to the fresh water base pulp, wherein the fresh water base pulp included 100g of fresh water and 5g of evaluation soil; the addition amount of the high temperature resistant modified starch was 1wt.%, 1.5 wt.% and 2wt.%, respectively recorded as the first starch-fresh water base pulp, the second starch-fresh water base pulp and the third starch-fresh water base pulp, the fresh water base pulp, the first starch-fresh water base pulp, the second starch-fresh water base pulp After the starch-fresh water base slurry and the third starch-fresh water base slurry were stirred at high speed for 5 minutes, the filter loss at room temperature was measured by a normal temperature pressure filter loss meter; For aging treatment, high temperature and high pressure filter loss meter was used to measure the fluid loss, so as to evaluate the temperature resistance and salt resistance of the modified starch. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com