Polyelectrolyte elastomer as well as preparation method and application thereof

A polyelectrolyte and elastomer technology, which is applied in the field of polyelectrolyte elastomer preparation, can solve the problems of dehydration and hardening failure, increase processing difficulty and production cost, etc., achieve low production cost, broad industrial application prospects, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned polyelectrolyte elastomer, which comprises the following steps: (a) dispersing the ionic monomer or / and polymer in water to form an aqueous solution; (b) adding an initiator to the aqueous solution for reaction to obtain polymerization (c) drying the polymer aqueous solution to form a film or 3D printing into various shapes; the drying conditions can be low temperature (minimum -180°C), room temperature or high temperature (maximum 200°C). The process does not involve any organic solvents, only one-step reaction is required, does not involve complex synthesis steps, and can be used for simple processing such as 3D printing. The preparation process is simple, green, environmentally friendly and pollution-free, and the preparation conditions are relatively loose. Broad commercial application prospects. In step (a), the solute mass concentration of the aqueous solution can be adjusted within the range of 0.1% to 99%; in step (b...

Embodiment 1

[0027] This embodiment provides a preparation method and application of a polyelectrolyte elastomer, specifically:

[0028] (a) Disperse 5 g of 3-(2-methacryloyloxyethyldimethylamino) propanesulfonate monomer in 30 mL of water, and stir evenly to obtain the monomer aqueous solution;

[0029] (b) adding 0.1 g of ammonium persulfate initiator to the above-mentioned aqueous monomer solution, and then placing it at 70° C. for heating reaction for 6 hours to obtain an aqueous polymer solution;

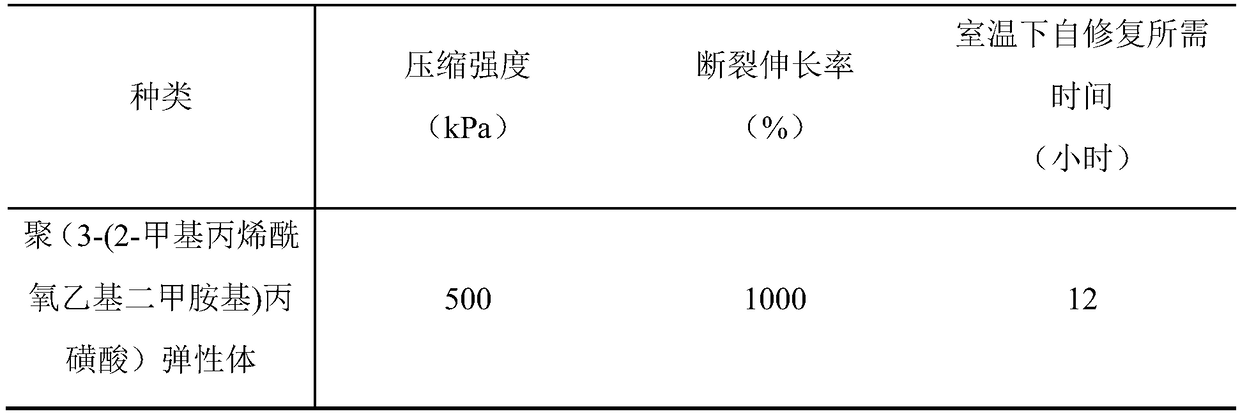

[0030] (c) drying the above-mentioned aqueous polymer solution into a film at room temperature to obtain a polyelectrolyte elastomer with compressible, stretchable and self-repairing effects; its mechanical properties are shown in Table 1, and it can be seen that the polyelectrolyte elastomer has 1000% elongation at break, high compressive strength and fast self-healing effect.

[0031] The above-mentioned polyelectrolyte elastomer is applied, specifically: two polyelectrolyte elastomers a...

Embodiment 2

[0035] This embodiment provides a preparation method and application of a polyelectrolyte elastomer, specifically:

[0036] (a) Disperse 2g of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate monomer and 1g of acrylic acid monomer in 2mL of water, and stir evenly to prepare an aqueous monomer solution;

[0037] (b) adding 0.2 g of ammonium persulfate initiator to the above-mentioned aqueous monomer solution, and then placing it at 50° C. for heating reaction for 24 hours to obtain an aqueous polymer solution;

[0038] (c) 3D print the above polymer aqueous solution (parameters: pressure 0.3MPa, temperature at room temperature, needle diameter 0.2mm, speed 1mm min-1), and dry at room temperature to form a polyelectrolyte elastomer with a designed shape .

[0039] The above-mentioned polyelectrolyte elastomer is applied, specifically: the bionic smart skin prepared by separating two polyelectrolyte elastomers with a polyacrylate film (thickness: 100 μm), and then connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com